Controllable water-soluble battery adhesive and preparation method thereof

A binder and water-soluble technology, applied in the field of polymer compounds, can solve the problems of battery charging efficiency and discharge efficiency discount, poor water solubility of polyimide film, and difficulty in maintaining the integrity of the pole piece, so as to increase the charging and discharging performance. Effects of cycle times, increased process controllability, and improved charge-discharge stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

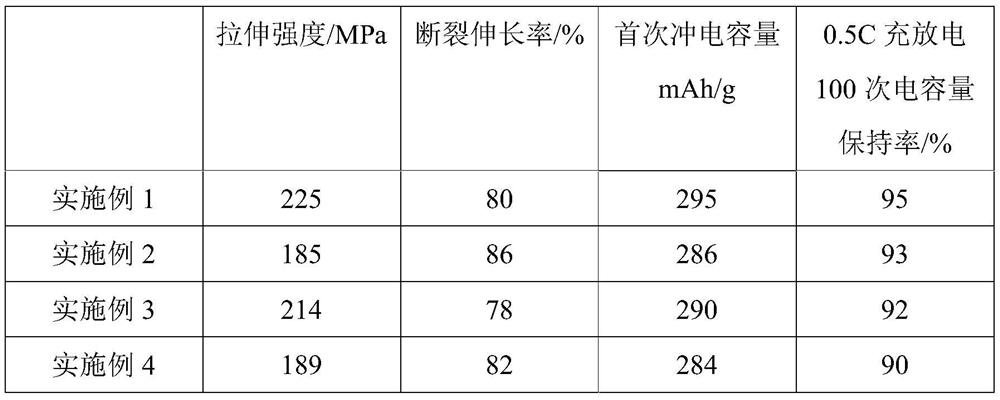

Examples

Embodiment 1

[0035]A controllable water-soluble battery binder, the raw materials for preparation include 3.7 parts by weight of aliphatic dianhydrides, 0.6 parts of aromatic diamines, 17 parts of solvents and 1.5 parts of catalysts.

[0036] The aliphatic dianhydride is a combination of 2-amino-3-fluorobicyclohexane dianhydride and 3,4-dicarboxy-1,2,3,4-tetrahydro-1-naphthalene succinic acid dianhydride, and the mass ratio 5:1.

[0037] The aromatic diamine is 4,4'-oxobiphenylenediamine.

[0038] The solvent is resorcinol, and the catalyst is pyridine.

[0039] A preparation method of a controllable water-soluble battery binder, comprising the following steps:

[0040] (1) Mix the aromatic diamine and the aliphatic dianhydride in a nitrogen atmosphere according to the weight ratio, add a solvent, and react at 90° C. for 6 hours;

[0041] (2) then adding a catalyst, heating up to 210 ° C, and reacting for 14 h to obtain a polymer;

[0042] (3) The polymer obtained in step 2 is washed a...

Embodiment 2

[0044] A controllable water-soluble battery binder, the raw materials for preparation include 3.7 parts by weight of aliphatic dianhydrides, 0.6 parts of aromatic diamines, 17 parts of solvents and 1.5 parts of catalysts.

[0045] The aliphatic dianhydride is a combination of fluorobicyclohexane dianhydride and 3,4-dicarboxy-1,2,3,4-tetrahydro-1-naphthalenesuccinic acid dianhydride, and the mass ratio is 5:1.

[0046] The aromatic diamine is 4,4'-oxobiphenylenediamine.

[0047] The solvent is resorcinol, and the catalyst is pyridine.

[0048] A preparation method of a controllable water-soluble battery binder, comprising the following steps:

[0049] (1) Mix the aromatic diamine and the aliphatic dianhydride in a nitrogen atmosphere according to the weight ratio, add a solvent, and react at 90° C. for 6 hours;

[0050] (2) then adding a catalyst, heating up to 210°C, and reacting for 14h to obtain a polymer;

[0051] (3) The polymer obtained in step 2 is washed and discharg...

Embodiment 3

[0053] A controllable water-soluble battery binder, the raw materials for preparation include 3.7 parts by weight of aliphatic dianhydrides, 0.6 parts of aromatic diamines, 17 parts of solvents and 1.5 parts of catalysts.

[0054] The aliphatic dianhydride is a combination of 2-amino-3-fluorobicyclohexane dianhydride and cyclohexanetetracarboxylic dianhydride, and the mass ratio is 5:1.

[0055] The aromatic diamine is 4,4'-oxobiphenylenediamine.

[0056] The solvent is resorcinol, and the catalyst is pyridine.

[0057] A preparation method of a controllable water-soluble battery binder, comprising the following steps:

[0058] (1) Mix the aromatic diamine and the aliphatic dianhydride in a nitrogen atmosphere according to the weight ratio, add a solvent, and react at 90° C. for 6 hours;

[0059] (2) then adding a catalyst, heating up to 210°C, and reacting for 14h to obtain a polymer;

[0060] (3) The polymer obtained in step 2 is washed and discharged.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com