Preparation method and application of static elimination adhesive tape

A static elimination and adhesive tape technology, applied in the direction of adhesives, film/sheet adhesives, film/sheet without carrier, etc., can solve wireless signal attenuation, affect signal transmission, change of reduction chemical properties, etc. Problems, to achieve Good stability, wide application range, and high static elimination efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

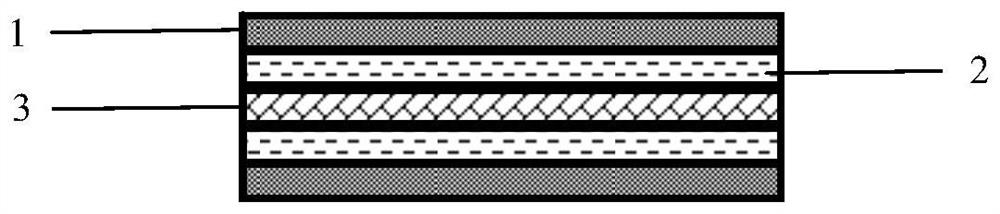

[0035] A preparation method of static elimination adhesive tape, comprising the following steps:

[0036] (1) The polyacrylic acid adhesive and cyclohexane are mixed and dispersed for 4h, and the rotating speed is 550r / min;

[0037] (2) Add carbon black, mix with ethylenediamine, continue stirring for 15h;

[0038] (3) carbon nanotubes are added, the silver-coated fiberglass continues to be mixed and stirred for 2.5h, and the material is discharged;

[0039] (4) Evenly coat the discharged material in step 3 on both sides of the PET substrate, then cover with a silicon-coated release film, and dry, and the oven temperature is 70°C.

[0040] The raw materials for the preparation of the static elimination tape include, in parts by weight, 25 parts of polyacrylic acid adhesive, 70 parts of cyclohexane, 7.5 parts of carbon black, 7 parts of ethylenediamine, 4 parts of carbon nanotubes, and 2 parts of silver-plated glass fibers.

[0041] The polyacrylic acid adhesive was purchased...

Embodiment 2

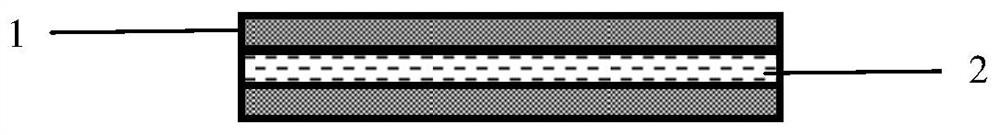

[0049] A preparation method of static elimination adhesive tape, comprising the following steps:

[0050] (1) The polyacrylic acid adhesive and toluene cyclohexanone are mixed and dispersed for 2h, and the rotating speed is 900r / min;

[0051] (2) adding silica, mixing with methylene bicyclohexaneamine, and continuing to stir for 9h;

[0052] (3) carbon nanotubes are added, the silver-coated fiberglass continues to be mixed and stirred for 2h, and then the material is discharged;

[0053] (4) Evenly coat the discharged material in step 3 on the middle of the two layers of silicon-coated release film, and dry it, and the oven temperature is 70°C.

[0054]The preparation raw materials of the static elimination tape include, in parts by weight, 20 parts of polyacrylic acid adhesive, 60 parts of toluene cyclohexanone, 6 parts of silicon dioxide, 5 parts of methylene bicyclohexane amine, 3 parts of carbon nanotubes, and silver plating. 1 part glass fiber.

[0055] The polyacrylic...

Embodiment 3

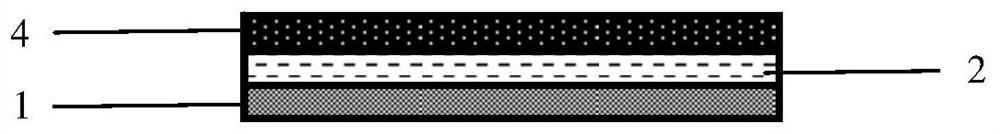

[0064] A preparation method of static elimination adhesive tape, comprising the following steps:

[0065] (1) The polyacrylic acid adhesive and N,N-dimethylformamide are mixed and dispersed for 5h, and the rotating speed is 300r / min;

[0066] (2) adding calcium oxide, mixing diethylenetriamine, and continuing to stir for 18h;

[0067] (3) carbon nanotubes are added, and the silver-coated fiberglass continues to be mixed and stirred for 3 hours, and then the material is discharged.

[0068] (4) Evenly coat the discharged material in step 3 on the matte black PI film, then cover with a silicon release film, and dry it, and the oven temperature is 70°C.

[0069] The raw materials for the preparation of the static elimination tape include, in parts by weight, 25 parts of polyacrylic acid adhesive, 70 parts of N,N-dimethylformamide, 7.5 parts of calcium oxide, 7 parts of diethylenetriamine, 5 parts of carbon nanotubes, and 5 parts of carbon nanotubes. 2 parts of silver fiberglass...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com