High-gloss water-based two-component finish paint as well as preparation method and application thereof

A high-gloss, two-component technology, used in coatings, polyurea/polyurethane coatings, etc., can solve problems such as compatibility between hydroxy acrylic resin and polyisocyanate, and achieve excellent adhesion performance, high hardness, Good leveling effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

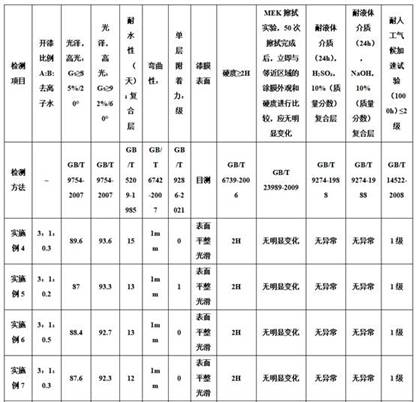

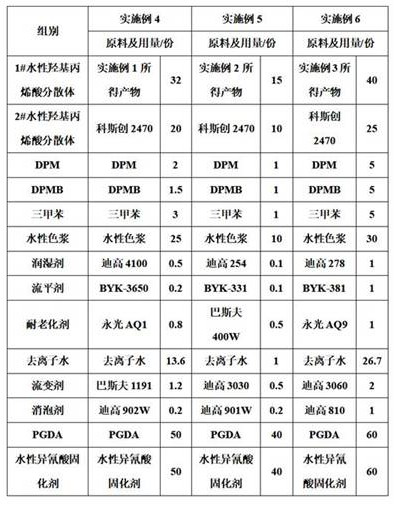

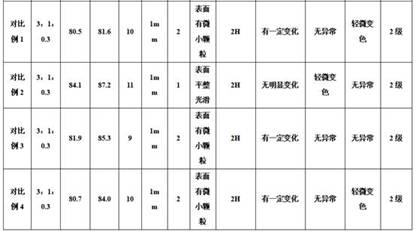

Examples

Embodiment 1

[0054] Example 1 Preparation method of 1# water-based hydroxyacrylic acid dispersion

[0055] The 1# water-based hydroxyacrylic acid dispersion includes the following raw materials by weight: 14 parts of styrene, 20 parts of methyl methacrylate, 12 parts of isobornyl acrylate, 11 parts of glycidyl tertiary carbonate, and 13 parts of butyl acrylate , 11 parts of hydroxyethyl methacrylate, 2 parts of acrylic acid, 3 parts of ethylene diamine, 10 parts of propylene glycol butyl ether, 4 parts of ethylene glycol butyl ether, and 96 parts of deionized water.

[0056] A: Resin synthesis process:

[0057] Step A1: Monomer premixing: all methyl methacrylate, isobornyl acrylate, 54% styrene, 20% butyl acrylate, 40% hydroxyethyl methacrylate, 15% acrylic acid, 1.9% initiator Add it into the mixing tank, stir evenly, and obtain component E; 23% styrene, 45% butyl acrylate, 60% hydroxyethyl methacrylate, 35% glycidyl tertiary carbonate, 45% acrylic acid, 2.3% initiator Add 23% styrene, ...

Embodiment 2

[0072] Example 2 Preparation method of 1# water-based hydroxyacrylic acid dispersion

[0073] The 1# water-based hydroxyacrylic acid dispersion includes the following raw materials by weight: 8 parts of styrene, 15 parts of methyl methacrylate, 5 parts of isobornyl acrylate, 5 parts of glycidyl tertiary carbonate, and 5 parts of butyl acrylate , 5 parts of hydroxyethyl methacrylate, 1 part of acrylic acid, 2 parts of ethylene diamine, 5 parts of propylene glycol butyl ether, and 96 parts of deionized water.

[0074] The preparation method is similar to Example 1. Wherein, the co-solvent in the component D is 50% propylene glycol butyl ether; in the step A2, the co-solvent is propylene glycol butyl ether.

Embodiment 3

[0075] Example 3 Preparation method of 1# water-based hydroxyacrylic acid dispersion

[0076] The 1# water-based hydroxyacrylic acid dispersion includes the following raw materials by weight: 20 parts of styrene, 25 parts of methyl methacrylate, 20 parts of isobornyl acrylate, 20 parts of glycidyl tertiary carbonate, and 30 parts of butyl acrylate , 20 parts of hydroxyethyl methacrylate, 10 parts of acrylic acid, 5 parts of ethylene diamine, 5 parts of trimethylbenzene and 10 parts of propylene glycol methyl ether, and 96 parts of deionized water.

[0077] The preparation method is similar to Example 1. Wherein, the cosolvent in the component D is 50% trimethylbenzene and 50% propylene glycol methyl ether; in the step A2, the cosolvent is 50% trimethylbenzene and 50% propylene glycol methyl ether.

PUM

| Property | Measurement | Unit |

|---|---|---|

| hardness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com