Durable polymer mortar for high-strength steel wire cloth reinforced concrete member

A high-strength steel wire and polymer technology, which is applied in the field of building material mortar preparation, can solve the problems of not considering freeze-thaw resistance, rust resistance, strength shrinkage, and few sources, so as to prevent the mortar layer from being corroded and improve the overall durability. , Improve the effect of bond strength

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

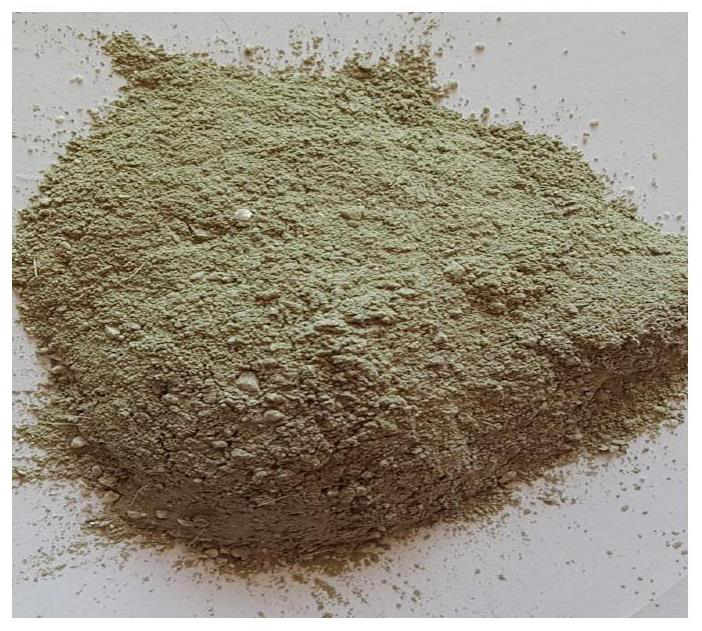

Image

Examples

Embodiment 1

[0035] A durable polymer mortar for reinforcing concrete members with high-strength steel wire cloth, cementing material 460kg (ordinary Portland cement 400kg, ultra-high-strength sulfoaluminate cement 60kg), graded quartz sand 473.5kg (using a particle size of 10 meshes) , 25 mesh, 50 mesh, and 80 mesh quartz sand are mixed in a mass ratio of 2:3:3:2), polymer powder 30kg, water reducing agent 2.5kg, thixotropic agent 0.5kg, retarder 1kg, coagulation accelerator 1.5kg of agent, 1kg of PP fiber, and 30kg of impermeable and rust-resistant admixture. The polymer mortar is uniformly prepared by pre-mixing. When using, mortar: water = 1:0.125 is mixed in proportion, and mechanical stirring is used to uniformly form a thick slurry.

Embodiment 2

[0037] A durable polymer mortar for reinforcing concrete members with high-strength steel wire cloth, cementing material 540kg (ordinary Portland cement 450kg, ultra-high-strength sulfoaluminate cement 90kg), graded quartz sand 393kg, polymer powder 30kg, reducing 3.0kg of water agent, 0.5kg of thixotropic agent, 1.5kg of retarder, 1kg of coagulant, 1kg of PP fiber, and 30kg of anti-freeze-thaw and anti-rust compacting agent. The polymer mortar is evenly prepared by pre-mixing and mixing. When using, mortar: water = 1:0.140 is mixed in proportion, and mechanical stirring is used to uniformly form a thick slurry.

[0038] The difference between Example 2 and Example 1 is that the cement and the corresponding admixtures and the content of quartz sand in Example 2 are different.

Embodiment 3

[0040] A durable polymer mortar for reinforcing concrete members with high-strength steel wire cloth, according to 460kg of cementitious materials (400kg of ordinary Portland cement, 60kg of ultra-high-strength sulfoaluminate cement), 458.5kg of graded quartz sand, and 45kg of polymer rubber powder , 2.5kg of water reducing agent, 0.5kg of thixotropic agent, 1kg of retarder, 1.5kg of accelerator, 1kg of PP fiber, 30kg of impermeable and rust-resistant compacting agent. The polymer mortar is uniformly prepared by pre-mixing and mixing. When using, mortar: water = 1:0.120 is mixed in proportion, and mechanical stirring is used to uniformly form a thick slurry.

[0041] The difference between Example 3 and Example 1 is that the amount of polymer rubber powder and the amount of quartz sand in Example 3 are different.

PUM

| Property | Measurement | Unit |

|---|---|---|

| length | aaaaa | aaaaa |

| tensile strength | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com