Copper-plated basalt fiber reinforced copper-based composite material as well as preparation method and application thereof

A copper-based composite material and basalt fiber technology, applied in chemical instruments and methods, metal material coating technology, other chemical processes, etc., can solve the problems of basalt fiber strength loss, unfavorable strength of copper-based composite materials, and improvement, etc. Achieve the effect of small gap, improved high temperature resistance and abundant resources

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

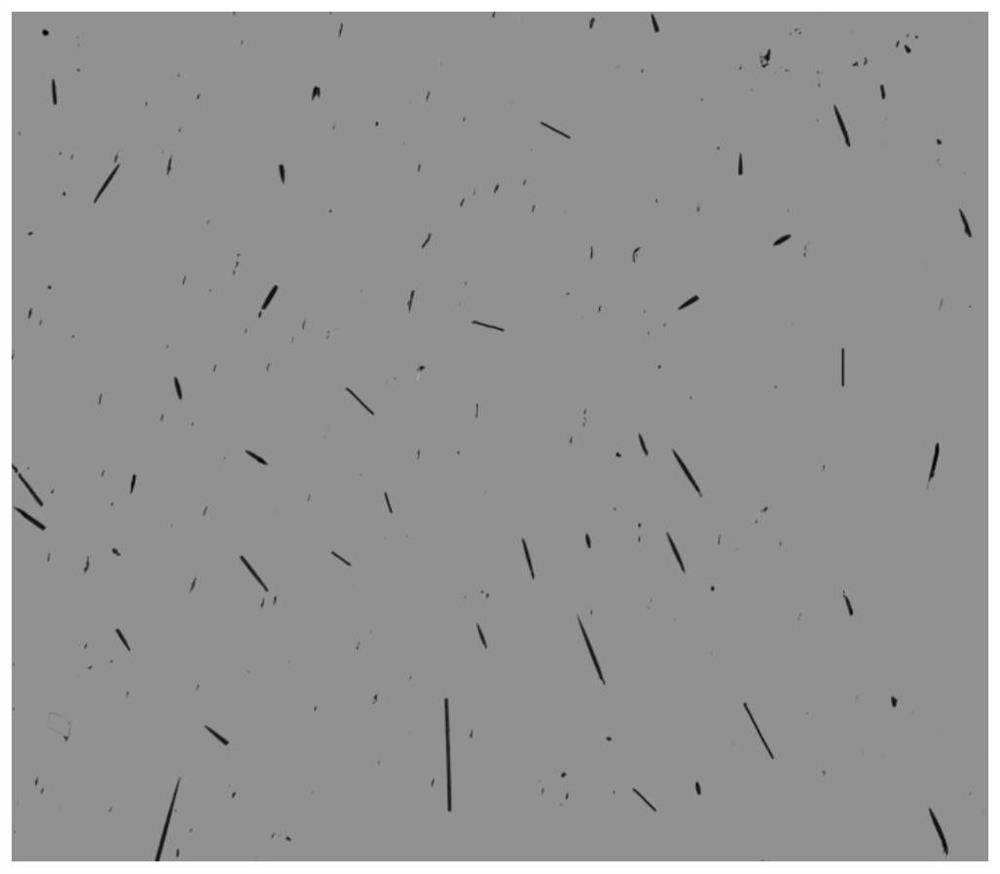

[0040] The present embodiment discloses a preparation method of a copper-plated basalt fiber-reinforced copper-based composite material, comprising the following steps:

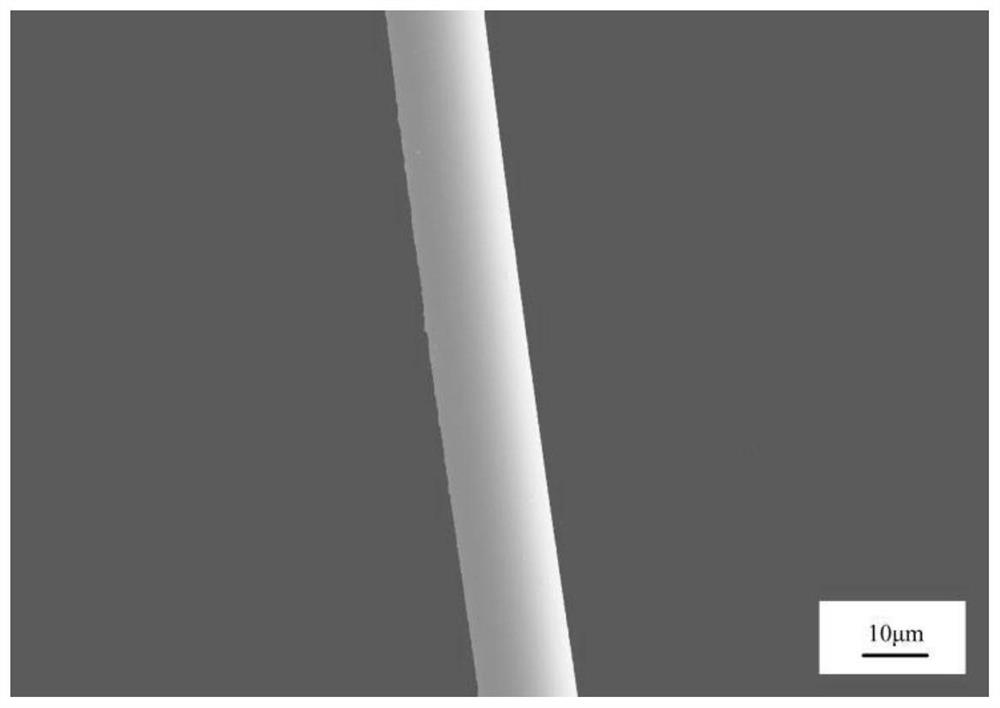

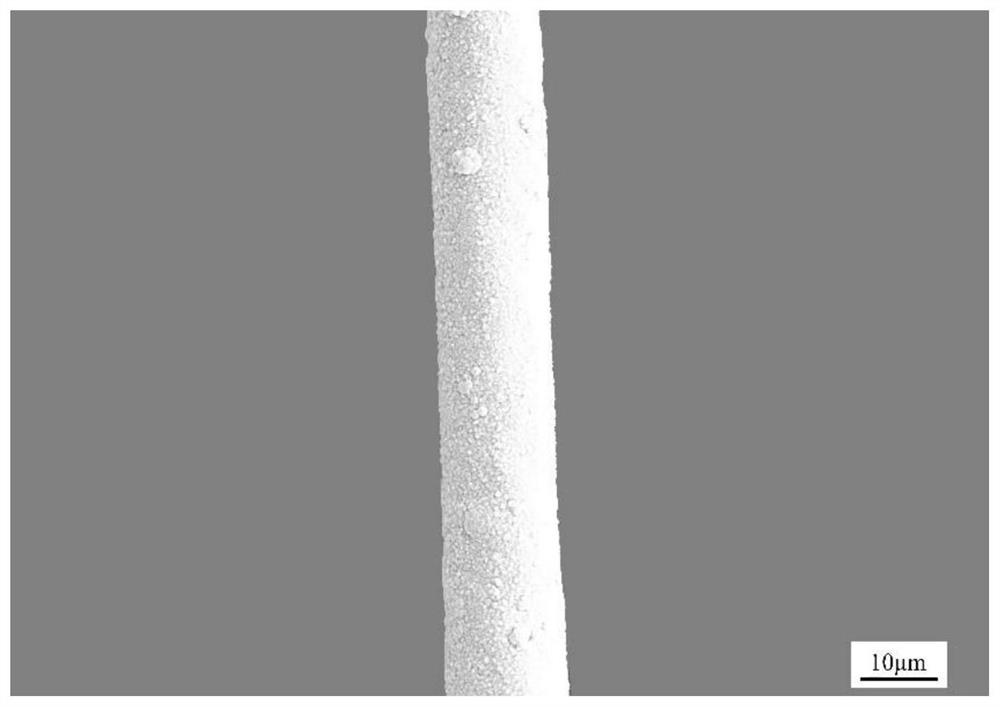

[0041](1) Put the original basalt fiber into the vacuum furnace, the vacuum degree is 1-3×10 -3 Pa, heated to 400°C, and kept for 20min. Turn off the power supply, and after the temperature in the furnace drops below 50°C, take out the basalt fiber from the furnace to obtain preheated basalt fiber. The original morphology of basalt fiber is as follows figure 1 shown.

[0042] (2) The basalt fiber obtained by the treatment in step (1) was soaked in a 4 wt.% HF solution for 10 min to carry out surface roughening treatment.

[0043] (3) Put the basalt fiber obtained in step (2) into the sensitizing solution for ultrasonic vibration for 30 minutes, then put it into the activation solution for ultrasonic vibration for 30 minutes, wash and dry with alcohol for many times. The formula of the sensitizing solution...

Embodiment 2

[0051] The present embodiment discloses a preparation method of a copper-plated basalt fiber-reinforced copper-based composite material, comprising the following steps:

[0052] (1) Put the original basalt fiber into the vacuum furnace, the vacuum degree is 1-3×10 -3 Pa, heated to 400°C, and kept for 20min. Turn off the power supply, and after the temperature in the furnace drops below 50°C, take out the basalt fiber from the furnace to obtain preheated basalt fiber.

[0053] (2) The basalt fiber obtained by the treatment in step (1) was soaked in a 4 wt.% HF solution for 10 min to carry out surface roughening treatment.

[0054] (3) Put the basalt fiber obtained in step (2) into the sensitizing solution for ultrasonic vibration for 30 minutes, then put it into the activation solution for ultrasonic vibration for 30 minutes, wash and dry with alcohol for many times. The formula of the sensitizing solution is: SnCl 2 , 20 g / L; 37 wt.% HCl, 40 mL / L; the remainder is deionized...

Embodiment 3

[0060] The present embodiment discloses a preparation method of a copper-plated basalt fiber-reinforced copper-based composite material, comprising the following steps:

[0061] (1) Put the original basalt fiber into the vacuum furnace, the vacuum degree is 1-3×10 -3 Pa, heated to 400°C, and kept for 20min. Turn off the power supply, and after the temperature in the furnace drops below 50°C, take out the basalt fiber from the furnace to obtain preheated basalt fiber.

[0062] (2) The basalt fiber obtained by the treatment in step (1) was soaked in a 4 wt.% HF solution for 10 min to carry out surface roughening treatment.

[0063] (3) Put the basalt fiber obtained in step (2) into the sensitizing solution for ultrasonic vibration for 30 minutes, then put it into the activation solution for ultrasonic vibration for 30 minutes, wash and dry with alcohol for many times. The formula of the sensitizing solution is: SnCl 2 , 20 g / L; 37 wt.% HCl, 40 mL / L; the remainder is deionized...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com