Low-volatility disinfectant and preparation method thereof

A low-volatility, disinfectant technology, applied in the direction of medical formula, organic active ingredients, inorganic active ingredients, etc., can solve the problems of key disinfection of parts that cannot be disinfected, alcohol-based disinfectants are volatile, and the efficacy is not long-lasting, etc., to achieve prolonged efficacy Action time, improve disinfection effect, improve the effect of protective effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1-5

[0039] A kind of low volatility disinfectant, its preparation method is:

[0040] S1. according to the proportioning in table 1, ethanol and propylene glycol are mixed to obtain mixed alcohol solution, nano molecular sieve is added in mixed alcohol solution, stand for 20min, obtain initial mixed solution, wherein nano molecular sieve particle size is 170nm;

[0041] S2. According to the proportioning of table 1, nano-zinc oxide sol, nano-titanium dioxide sol, nano-molecular sieve, and water are added to the initial mixed solution, mixed evenly, and sealed and stored to obtain a low-volatility disinfectant.

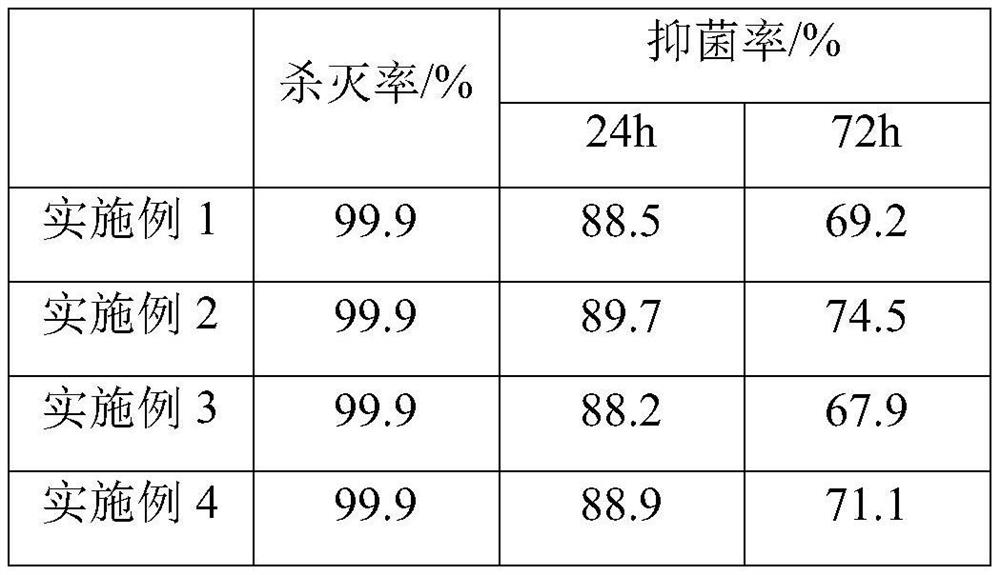

[0042] Table 1 embodiment 1-5 raw material proportioning table (kg)

[0043] Example 1 Example 2 Example 3 Example 4 Example 5 Ethanol 50 60 70 60 60 Propylene Glycol 30 25 20 25 25 Nano zinc oxide sol 20 30 40 27.5 33 Nano Titanium Dioxide Sol 30 25 20 27.5 22 Nano molecular sieve 35 40 50 40 40 wat...

Embodiment 6-8

[0045] Different from Example 2, Examples 6-8 also include 5kg, 10kg, and 20kg of film-forming agents, respectively. The film-forming agent is added in step S2, and the film-forming agent is gelatin.

Embodiment 9

[0047] Different from Example 7, the film-forming agent in Example 9 is chitosan.

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| degree of polymerization | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com