Preparation process of wear-resistant bending-resistant pipe

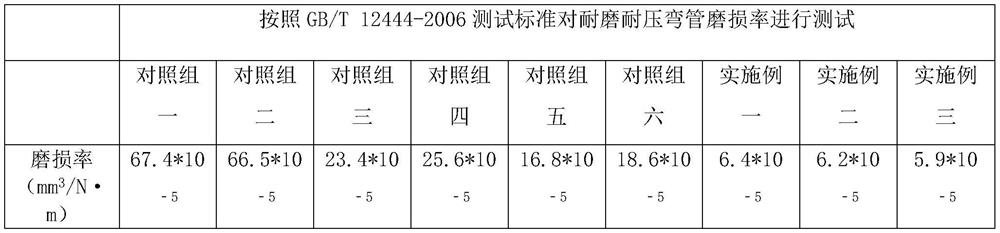

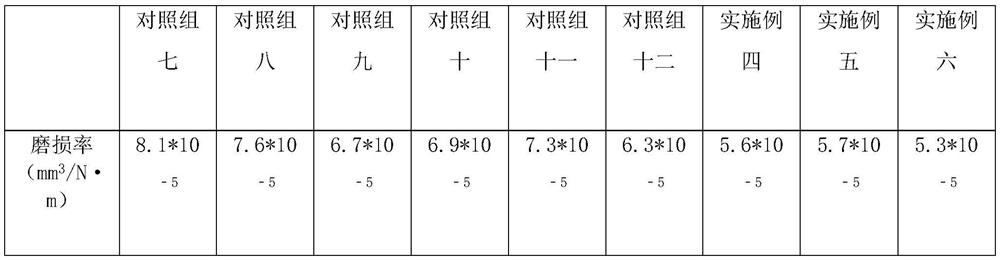

A preparation process and technology of preparation steps are applied in the field of preparation technology of wear-resistant and pressure-resistant elbows, which can solve the problems of inconvenient maintenance, serious wear and corrosion of the inner wall of the elbows, and easy damage, so as to ensure the pressure resistance, strengthen the bonding effect and The effect of uniform distribution and the effect of reducing the surface wear rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0031] The invention provides a preparation process of a wear-resistant and pressure-resistant elbow, and the specific preparation steps are as follows:

[0032] Step 1: Use the stainless steel pipe as the inner lining layer and the straight seam welded pipe as the outer base layer to adopt the hydroforming method to make the bimetal composite pipe;

[0033] Step 2: Use bimetal composite pipe for hot push processing to make a pressure-resistant elbow;

[0034] Step 3: Spray the inner and outer walls of the elbow with PTFE composite material to obtain a semi-finished wear-resistant and pressure-resistant elbow;

[0035] Step 4: The semi-finished wear-resistant and pressure-resistant elbow is treated by plasma enhanced chemical vapor deposition to obtain the wear-resistant and pressure-resistant elbow;

[0036] The polytetrafluoroethylene composite material, calculated by weight percentage, includes: 3.6% polyethylene oxide, 9.6% wollastonite, 15.6% polyvinylpyrrolidone, 8.6% c...

Embodiment 2

[0046] The difference from Example 1 is that in step 1, in the hydroforming method, the bulging pressure is 180MPa, the initial gap is 2.5mm, and the wall thickness of the liner is 4mm; in step 2, during the hot pushing process, the heating temperature is 980°C , the holding time is 3min; the cooling rate of water spray is 15℃ / s; the tempering temperature is 510℃, and the holding time is 51min; in step 3, electrostatic spraying is used, the electrostatic high voltage is 80KV, the electrostatic current is 20μA, and the flow rate is The pressure is 0.45MPa, the atomization pressure is 0.40MPa, and the distance between the nozzle of the spray gun and the pipe wall is 260mm; in step 4, during the plasma enhanced chemical vapor deposition process, the semi-finished wear-resistant and pressure-resistant elbow is placed in the plasma enhanced The inside of the deposition chamber in the chemical vapor deposition equipment is evacuated, and then nitrogen gas is introduced for pretreatme...

Embodiment 3

[0048] Different from Examples 1-2, in step 1, in the hydroforming method, the bulging pressure is 170MPa, the initial gap is 2.0mm, and the wall thickness of the liner is 3mm; in step 2, during the hot pushing process, the heating temperature is The temperature is 965°C, the holding time is 2.5min; the cooling rate of water spray is 12°C / s; the tempering temperature is 495°C, and the holding time is 48min; is 15μA, the flow rate pressure is 0.40MPa, the atomization pressure is 0.38MPa, and the distance between the nozzle of the spray gun and the pipe wall is 245mm; in step 4, during the plasma enhanced chemical vapor deposition treatment process, put the semi-finished wear-resistant and pressure-resistant elbow into the Go to the inside of the deposition chamber in the plasma-enhanced chemical vapor deposition equipment, evacuate, and then pass nitrogen for pretreatment, and at the same time pass methane for deposition; 170W, growth for 75min, and reaction temperature of 360℃...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com