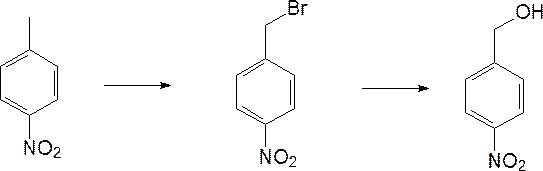

Production process of p-nitrobenzyl alcohol

A technology for the production of p-nitrobenzyl alcohol, applied in the preparation of organic compounds, organic chemistry, chemical instruments and methods, etc., can solve the problems of high production cost and high heat energy consumption, reduce heat energy consumption, improve reaction efficiency, The effect of improving production safety

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

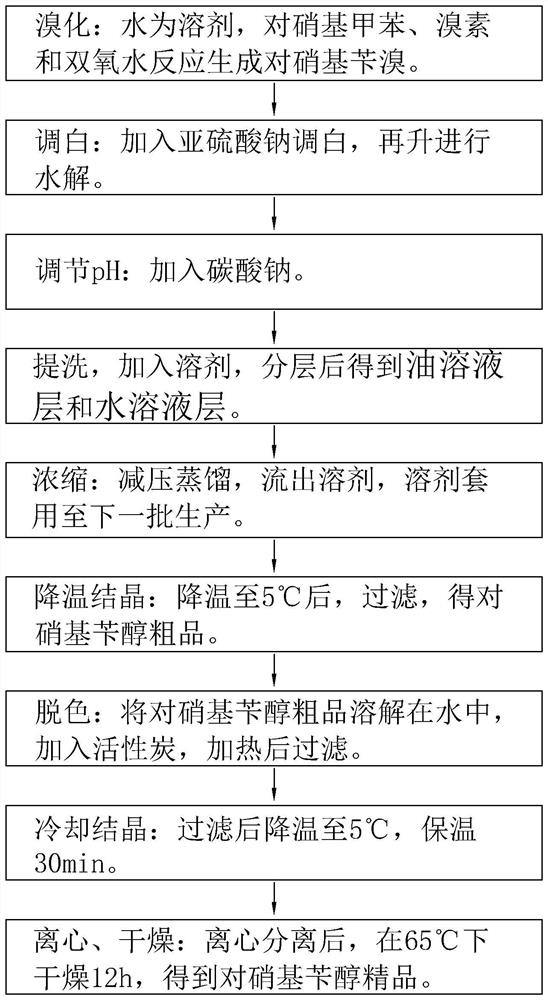

Method used

Image

Examples

preparation example 1

[0039] Preparation of catalyst:

[0040] The ZSM-5 molecular sieve was soaked in ferric sulfate solution, taken out and dried at 100°C for 12 hours, and then calcined at 500-°C for 6 hours to obtain the iron-loaded molecular sieve. The ZSM-5 molecular sieve was loaded with 1wt% iron.

preparation example 2

[0042] Preparation of catalyst:

[0043] The ZSM-5 molecular sieve was soaked in ferric sulfate solution, removed and dried at 100 °C for 12 h, and then calcined at 550 °C for 4 h to obtain an iron-loaded molecular sieve. The ZSM-5 molecular sieve was loaded with 1wt% iron.

preparation example 3

[0045] Preparation of catalyst:

[0046] The ZSM-5 molecular sieve was soaked in the ferric sulfate solution, removed and dried, and then calcined at 520 °C for 5 h to obtain the iron-loaded molecular sieve. The ZSM-5 molecular sieve was loaded with 1wt% iron.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com