Super-wear-resistant and low-temperature-resistant glassy-state hydrophobic coating, preparation method of coating and coating

A hydrophobic coating and hydrophobic coating technology, applied in the field of coatings, can solve the problems of sand and stone wear resistance, low temperature resistance and pollution resistance, self-cleaning, aging resistance, acid and alkali resistance, etc., so as to improve the ability of low temperature environment and sand resistance. Stone wear and impact ability is strong, the effect of small wear volume

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

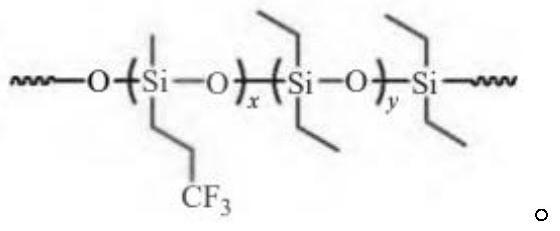

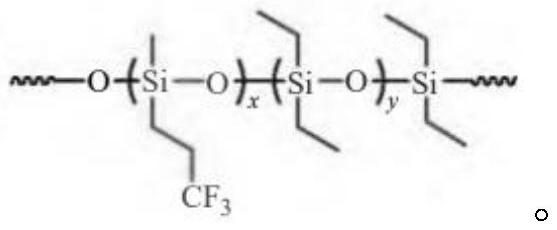

[0028] In this embodiment, the initiator is DuPont AIBN azobisisobutyronitrile (V60 / VAZO64); PDES-ran-PTFPMS is a fluorine-containing copolysiloxane prepared by phosphazene alkali-catalyzed ring-opening polymerization; the curing agent is Covestro N3600; UV absorber is Tinuvin 622 from BASF; diluent is xylene, ethyl acetate, n-butyl acetate, and propylene glycol monomethyl ether mixed in a mass ratio of 4:4:1:1.

[0029] The preparation method of the ultra-wear-resistant and low-temperature resistant glassy hydrophobic coating comprises the following steps:

[0030] Step S1, accurately weigh 2g initiator, 32g methacryloxysilane, 38g hydroxyethyl methacrylate and 3g diluent and place them in a three-necked flask, feed nitrogen, stir, and react at 80°C 5h, due to the high viscosity of the reaction system, 2g of diluent was added, and the reaction was continued for 3h to obtain a modified prepolymer to obtain a modified prepolymer.

[0031] Step S2-1, using an ice-water bath to ...

Embodiment 2

[0037] In this embodiment, the initiator is DuPont AIBN azobisisobutyronitrile (V60 / VAZO64); PDES-ran-PTFPMS is a fluorine-containing copolysiloxane prepared by phosphazene alkali-catalyzed ring-opening polymerization; the curing agent is Covestro N3390; UV absorber is Tinuvin 622 from BASF; diluent is ethyl acetate.

[0038] The preparation method of the ultra-wear-resistant and low-temperature resistant glassy hydrophobic coating comprises the following steps:

[0039] Step S1, accurately weigh 2 g of initiator, 25 g of methacryloyloxysilane, 32 g of hydroxyethyl methacrylate and 3 g of diluent, place them in a three-necked flask, feed nitrogen, and react at 80° C. for 5.5 h to obtain a modified prepolymer.

[0040] In step S2-1, using an ice-water bath, the temperature of the modified prepolymer prepared in step S1 is lowered to 18° C., and then the diluent is poured into it to adjust the solid content to 20% (determine by testing whether the solid content reaches 20%) , ...

Embodiment 3

[0046] In this embodiment, the initiator is Huaxiang Kejie azobisisoheptanenitrile 4419-11-8ABVN V65; PDES-ran-PTFPMS is a fluorine-containing copolysiloxane prepared by phosphazene alkali-catalyzed ring-opening polymerization; the curing agent It is Covestro N3600; the UV absorber is BASF's Tinuvin400; the diluent is xylene.

[0047] The preparation method of the ultra-wear-resistant and low-temperature resistant glassy hydrophobic coating comprises the following steps:

[0048] Step S1, accurately weigh 3g of initiator, 35g of methacryloxysilane, 30g of hydroxyethyl methacrylate and 3g of diluent, place them in a three-necked flask, pass nitrogen gas, and react at 82°C for 5h , due to the high viscosity of the reaction system, 1 g of diluent was added, and the reaction was continued for 3.5 h to obtain a modified prepolymer.

[0049] In step S2-1, using an ice-water bath, the temperature of the modified prepolymer prepared in step S1 is lowered to 18° C., and then the dilue...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com