Bifunctional composite material with ultra-small Ru nanoclusters loaded on MoO3-x nanobelts and preparation method and application of bifunctional composite material

A nano-cluster, composite material technology, applied in electrolysis components, electrodes, electrolysis process, etc., can solve the problems of scarcity of palladium and platinum reserves, restricting large-scale application, high price, etc., and achieves many active sites and excellent electrocatalysis. Activity, low reaction risk effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

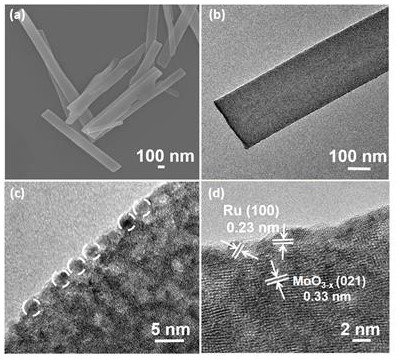

[0031] (1) Dissolve 0.5g of ammonium molybdate and chromium chloride in 25mL of deionized water, mix them uniformly by ultrasonic, and then inject 5mL of concentrated nitric acid, continue to stir evenly, and transfer them to the reaction kettle, and place the reaction kettle in an oven for 200 The hydrothermal reaction was carried out at ℃ for 3 hours. After the reaction, the MoO was obtained by centrifugation and washing several times. 3 nanoribbons;

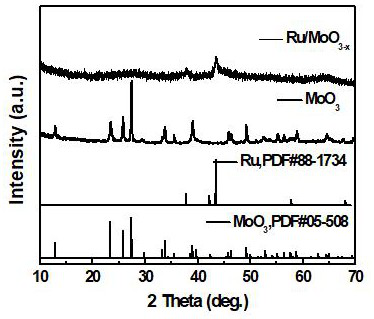

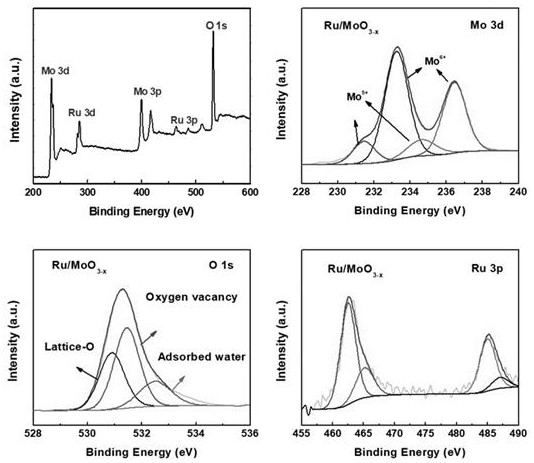

[0032] (2) 0.02g MoO 3 The nanobelts and 2.7 mg of ruthenium chloride were dispersed in 10 mL of water, immersed in ultrasonic waves for 2 hours, freeze-dried, and placed in a tube furnace in an argon-protected hydrogen atmosphere (the volume fraction of hydrogen was 5%) at 350 °C Reduction for 3 hours to obtain ultra-small Ru nanoclusters supported on MoO 3-x Bifunctional composites of nanoribbons.

Embodiment 2

[0034] (1) Dissolve 0.6g of ammonium molybdate and chromium chloride in 25mL of deionized water, mix them uniformly by ultrasonic, and then inject 5mL of concentrated nitric acid, continue to stir them evenly, and transfer them to the reaction kettle. Place the reaction kettle in an oven for 200 The hydrothermal reaction was carried out at ℃ for 4 hours. After the reaction, the MoO was obtained by centrifugation and washing several times. 3 nanoribbons;

[0035] (2) 0.03g MoO 3 The nanobelts and 3.0 mg of ruthenium chloride were dispersed in 10 mL of water, immersed in ultrasonic waves for 3 hours, freeze-dried, and placed in a tube furnace in an argon-protected hydrogen atmosphere (the volume fraction of hydrogen is 10%) at 450 °C Reduction for 2 hours to obtain ultra-small Ru nanoclusters supported on MoO 3-x Bifunctional composites of nanoribbons.

Embodiment 3

[0037] (1) Dissolve 1.0 g of ammonium molybdate and chromium nitrate in 50 mL of deionized water, mix them uniformly by ultrasonic, and then inject 10 mL of concentrated hydrochloric acid, continue to stir evenly, and transfer them to the reaction kettle, and place the reaction kettle in an oven at 180°C Under the hydrothermal reaction for 4 hours, after the reaction, centrifugal washing several times to obtain MoO 3 nanoribbons;

[0038] (2) 0.2g MoO 3 The nanobelts and 27 mg of ruthenium chloride were dispersed in 100 mL of water, immersed in ultrasonic for 3 hours, freeze-dried, and placed in a tube furnace in an argon-protected hydrogen atmosphere (the volume fraction of hydrogen was 5%) at 400 °C Reduction for 2 hours to obtain ultra-small Ru nanoclusters supported on MoO 3-x Bifunctional composites of nanoribbons.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com