Synthesis method and application of two-dimensional layered tungsten nitride nanoparticles

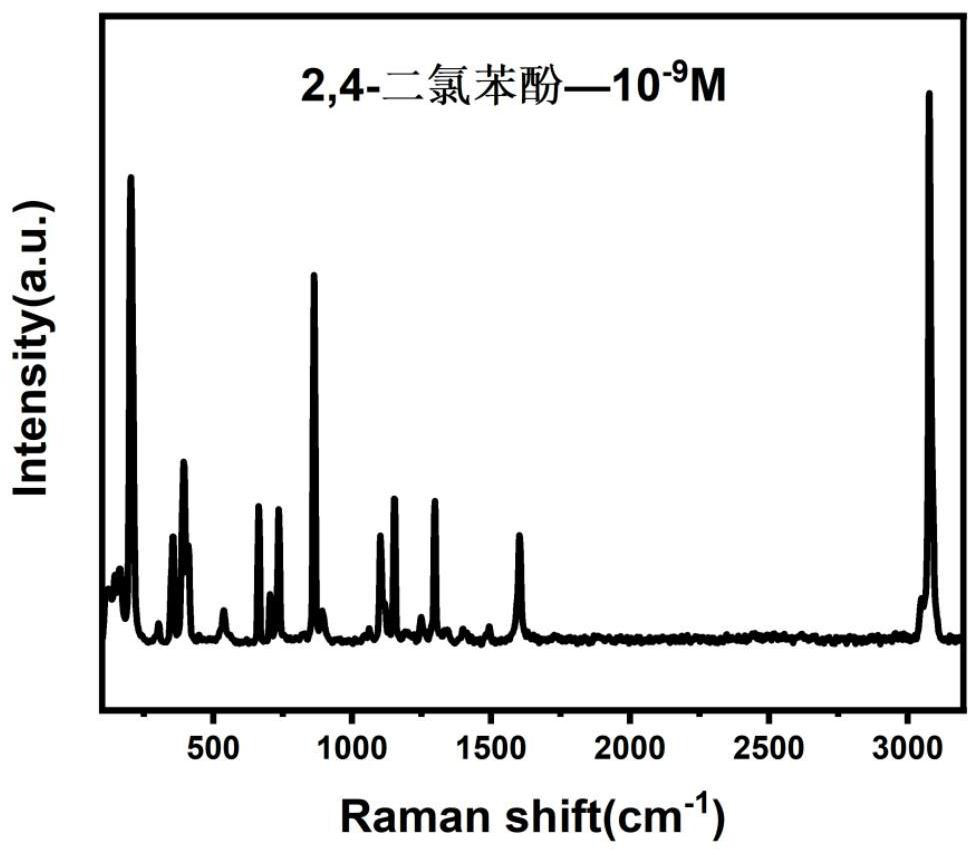

A technology of tungsten nitride nanometer synthesis method, which is applied in the direction of nitrogen-metal/silicon/boron binary compound, material excitation analysis, Raman scattering, etc., can solve the problems of irregular material shape and lengthy steps, etc. Regular appearance, good repeatability and stability, strong manipulation effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0043] This embodiment provides a method for preparing two-dimensional layered tungsten nitride nanoparticles:

[0044] 1) 5g of tungsten hexachloride was added to the ethanol solution of 99.5% in 300mL of ethanol solution, the rotating speed of 300r / min was magnetically stirred until the solution became pale yellow, and it was transferred into the 100mL reaction kettle at 120°C in the blast drying oven. Hold for 12h. After cooling to room temperature, it was transferred to a centrifuge tube, centrifuged (centrifugation speed 8000r / min, centrifugation time 6min), washed with deionized water, repeated 3 times, and the sample was kept in a blast drying oven at 55°C for 12h to dry.

[0045] 2) Place the dried sample in a tube furnace, feed into a mixed gas of nitrogen and ammonia (the flow rate of ammonia gas is 5mL / min, and the flow rate of nitrogen gas is 2mL / min), and the temperature is raised to 6°C / min. 720°C and kept for 8h to obtain the final sample.

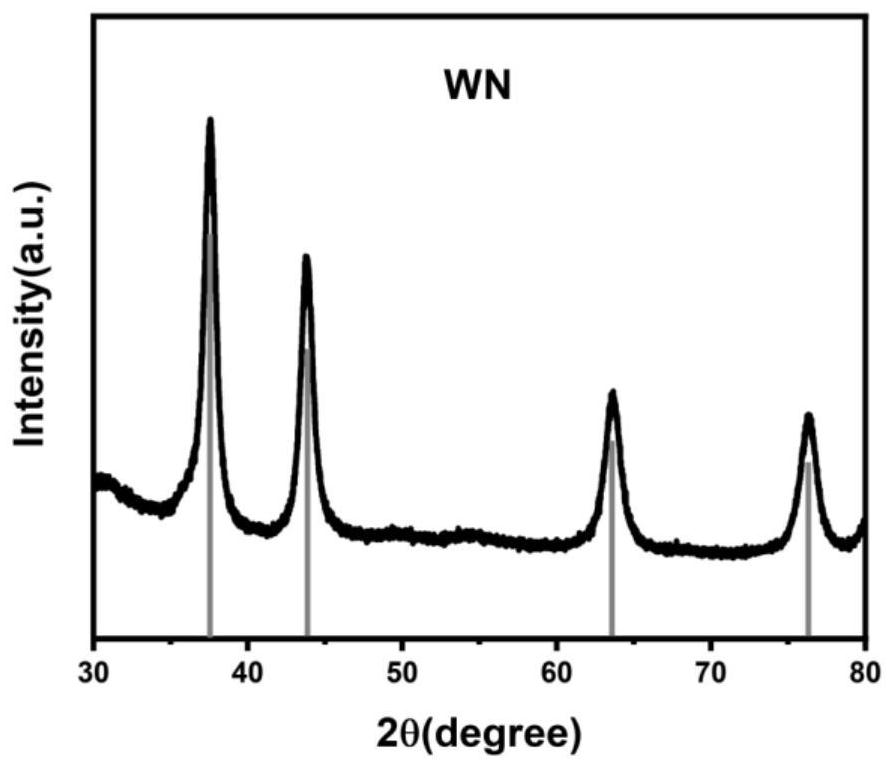

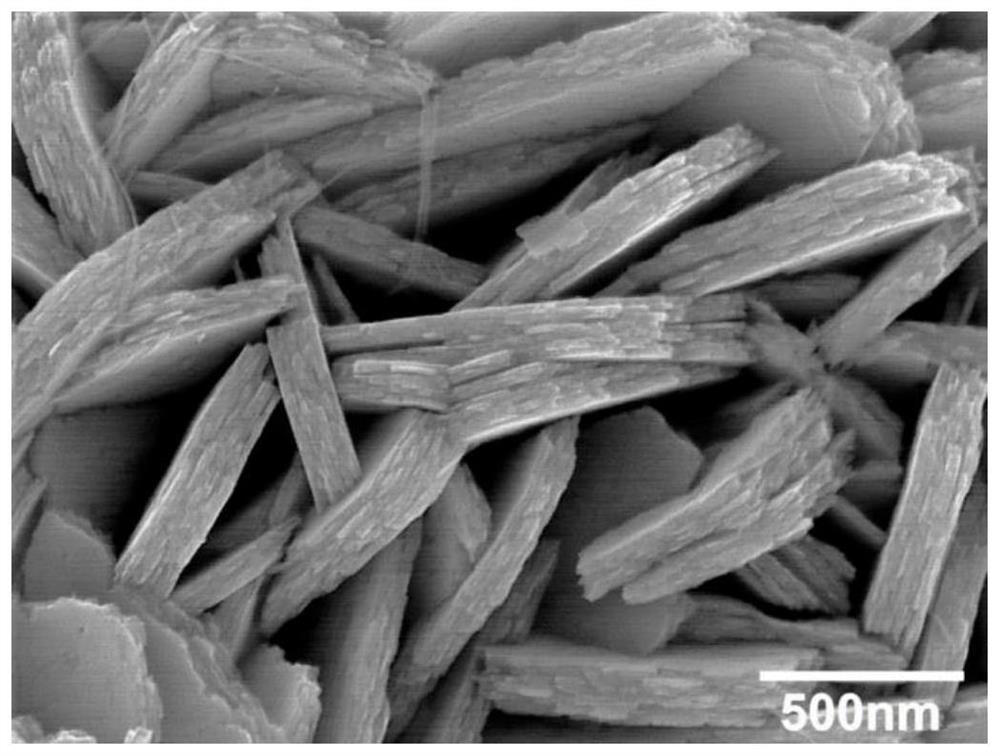

[0046] The obtaine...

Embodiment 2

[0048] This embodiment provides a method for preparing two-dimensional layered tungsten nitride nanoparticles:

[0049] 4.5g of tungsten hexachloride was added to the 300mL ethanol solution with a concentration of 99.5%, the rotating speed of 280r / min was magnetically stirred until the solution became pale yellow, transferred to a 100mL reaction kettle and kept at 110°C in a blast drying oven. 10h. After cooling to room temperature, it was transferred to a centrifuge tube, centrifuged (centrifugation speed 8500 r / min, centrifugation time 4 min), washed with deionized water, repeated 3 times, and the sample was kept in a blast drying oven at 60 °C for 10 h to dry.

[0050]2) Place the dried sample in a tube furnace, feed into a mixed gas of nitrogen and ammonia (the flow rate of ammonia gas is 7mL / min, and the flow rate of nitrogen gas is 3.5mL / min), and the temperature rises at a heating rate of 1°C / min. to 700°C and kept for 6h to obtain the final sample.

[0051] The obtai...

Embodiment 3

[0053] This embodiment provides a method for preparing two-dimensional layered tungsten nitride nanoparticles:

[0054] Add 4g of tungsten hexachloride to 300mL of ethanol solution with a concentration of 99.5%, stir magnetically at a speed of 260r / min until the solution turns light yellow, transfer it to a 100mL reaction kettle and keep it in a blast drying oven at 100°C for 4h . After cooling to room temperature, it was transferred to a centrifuge tube, centrifuged (centrifugation speed 9000r / min, centrifugation time 5min), washed with deionized water, and after repeated 3 times, the samples were kept in a blast drying oven at 75°C for 7h to dry.

[0055] 2) Place the dried sample in a tube furnace, feed the mixed gas of nitrogen and ammonia (the flow rate of ammonia gas is 5mL / min, and the flow rate of nitrogen gas is 2mL / min), and heat up to 3°C / min at a heating rate. 710°C and kept for 4h to obtain the final sample.

[0056] The obtained final sample was XRD ( Figure ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com