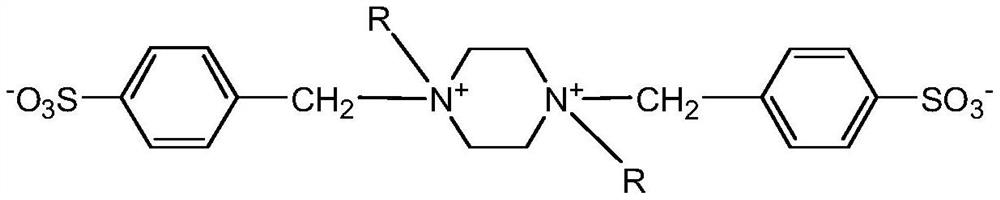

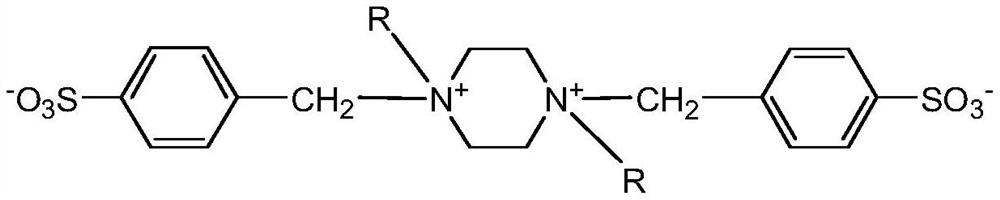

Discharge aiding agent for acid fracturing and preparation method of discharge aiding agent

A technology of acidizing fracturing and drainage aids, which is applied in the direction of chemical instruments and methods, organic chemistry, and drilling compositions. The effect of low dosage, simple synthesis and preparation process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

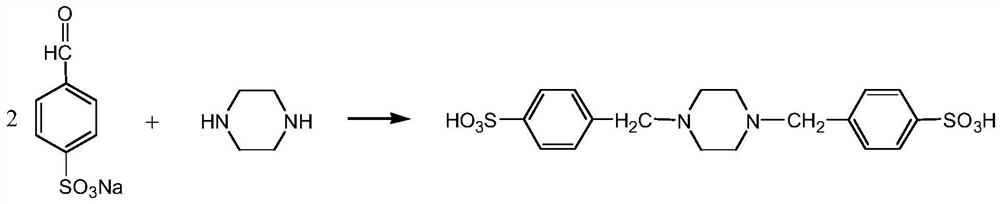

[0037] (1) 0.05mol piperazine (4.32g), 0.10mol sodium p-formaldehyde benzene sulfonate, 0.10mol sodium cyanoborohydride, 12.96g methanol, 0.216g 30wt% hydrochloric acid were sequentially added to the first reactor, while stirring Heating, refluxing for 4h, adding 1M sodium hydroxide solution to adjust pH3-5;

[0038] (2) in above-mentioned mixed solution, add 12.96g chloroform, extract, evaporate to dryness by rotary evaporator, obtain intermediate product;

[0039] (3) above-mentioned intermediate product was transferred to the second reactor with 16.88g ethanol, 0.09mol bromobutane was added, heated to reflux for 4h, and evaporated to dryness by rotary evaporator to obtain crude product;

[0040] (4) Add 12.96g of n-hexane to the above crude product, heat up to dissolve, filter, cool the filtrate to below 10°C, separate out crystals, filter, and dry at 80°C for 3 hours to obtain the product, a drainage aid S for acid fracturing. 1 .

Embodiment 2

[0042] (1) 0.05mol piperazine (4.32g), 0.13mol sodium p-formaldehyde benzene sulfonate, 0.13mol sodium cyanoborohydride, 43.2g methanol, 0.864g 30wt% hydrochloric acid were successively added to the first reactor, while stirring Heating, refluxing for 6h, adding 1M sodium hydroxide solution to adjust pH3-5;

[0043] (2) in above-mentioned mixed solution, add 43.2g chloroform, extract, evaporate to dryness by rotary evaporator, obtain intermediate product;

[0044] (3) above-mentioned intermediate product was transferred to the second reactor with 43.2g ethanol, added 0.12mol bromododecane, heated to reflux for 7h, evaporated to dryness by rotary evaporator to obtain crude product;

[0045] (4) Add 34.56g of n-hexane to the above crude product, heat up to dissolve, filter, cool the filtrate to below 10°C, separate out crystals, filter, and dry at 90°C for 2 hours to obtain the product, a drainage aid S for acid fracturing. 2 .

Embodiment 3

[0047](1) 0.05mol piperazine (4.32g), 0.111mol sodium p-formaldehyde benzene sulfonate, 0.112mol sodium cyanoborohydride, 20.16g methanol, 0.39g 30wt% hydrochloric acid were successively added to the first reactor, while stirring Heating, refluxing for 8h, adding 1M sodium hydroxide solution to adjust pH3-5;

[0048] (2) in above-mentioned mixed solution, add 20.88g chloroform, extract, evaporate to dryness by rotary evaporator, obtain intermediate product;

[0049] (3) above-mentioned intermediate product is transferred to the second reactor with 12.96g ethanol, adds 0.099mol bromododecane, heats under reflux for 8h, and evaporates to dryness by rotary evaporator to obtain crude product;

[0050] (4) Add 18.44g of n-hexane to the above crude product, heat up to dissolve, filter, cool the filtrate to below 10°C, separate out crystals, filter, and dry at 80°C for 2 hours to obtain the product, a drainage aid S for acid fracturing. 3 .

PUM

| Property | Measurement | Unit |

|---|---|---|

| surface tension | aaaaa | aaaaa |

| surface tension | aaaaa | aaaaa |

| interfacial tension | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com