Preparation method of high-plasticizing and anti-migration cardanol-based plasticizer

A cardanol-based polyoxyethylene ether and anti-migration technology, applied in the field of plasticizers, can solve the problems of low plasticization efficiency and migration risk in plasticizing properties, achieve excellent ductility, realize high-value utilization, and be practical sexual effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0035] The preparation method of cardanol-based polyoxyethylene ether fatty acid ester, the steps are as follows:

[0036] 1) Synthesis of cardanol-based polyoxyethylene ether:

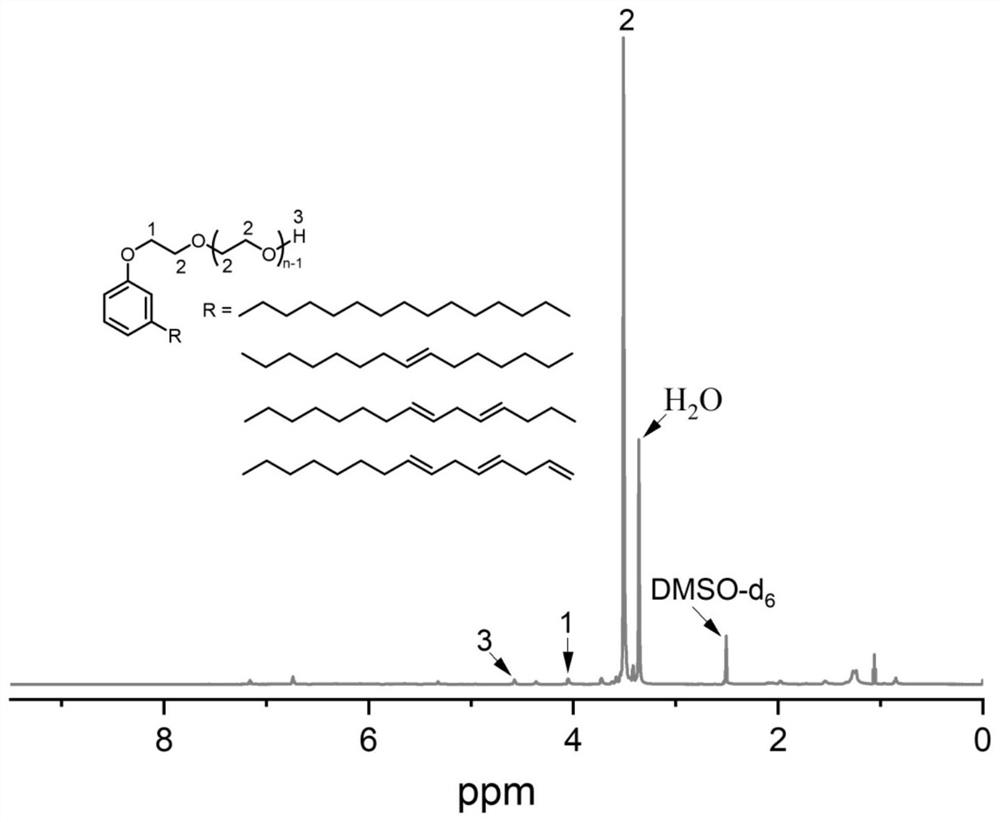

[0037] Add 328g cardanol, 3.8g KOH to the closed autoclave, use N 2 Replace 3 to 5 times, then under the condition of temperature of 90 to 100 ℃, vacuum dehydration for 20 to 60 minutes, add 3076g of ethylene oxide under the condition of temperature of 110 to 120 ℃ to start the reaction, and control by condensed water during the feeding process The reaction temperature is 120-125 ℃, the pressure in the kettle is 0.1 MPa-0.3 MPa, and the reaction is completed by aging for 60 min after feeding, cooling to 60 ℃, adding phosphoric acid for neutralization, then adding 5 g of activated clay, adsorbing at 60 ℃ for 1 hour, and filtering, To obtain cardanol polyoxyethylene ether with a molecular weight of 3129 g / mol, the hydrogen nuclear magnetic spectrum is as follows figure 1 shown.

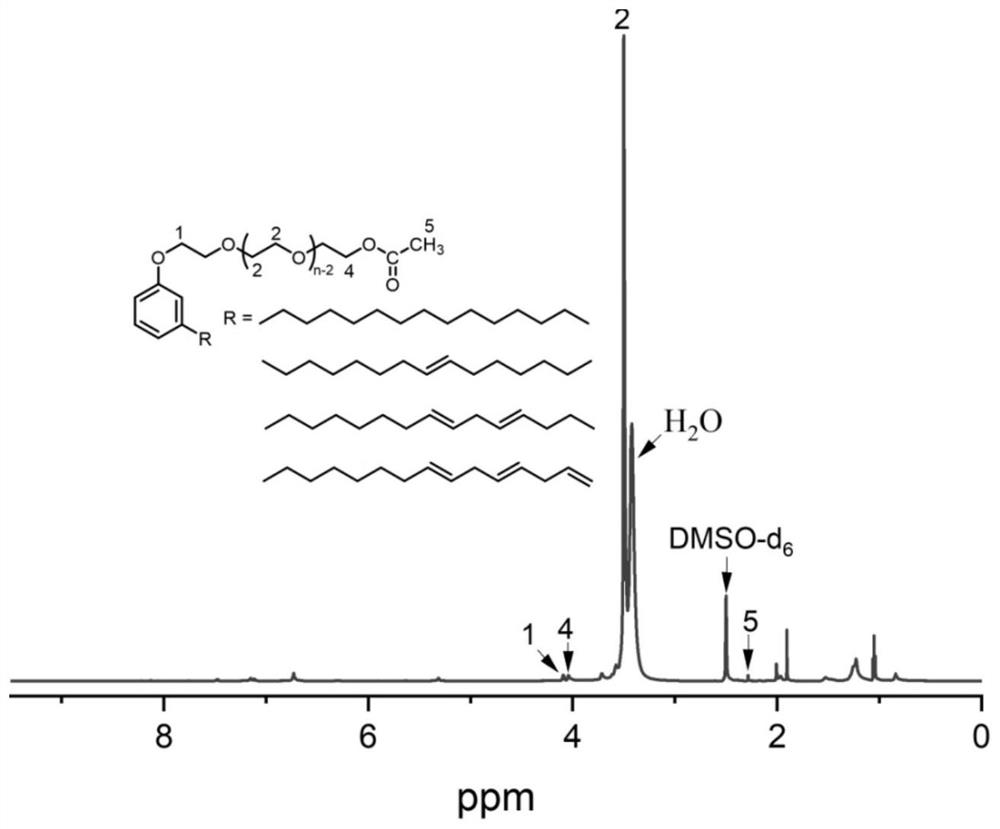

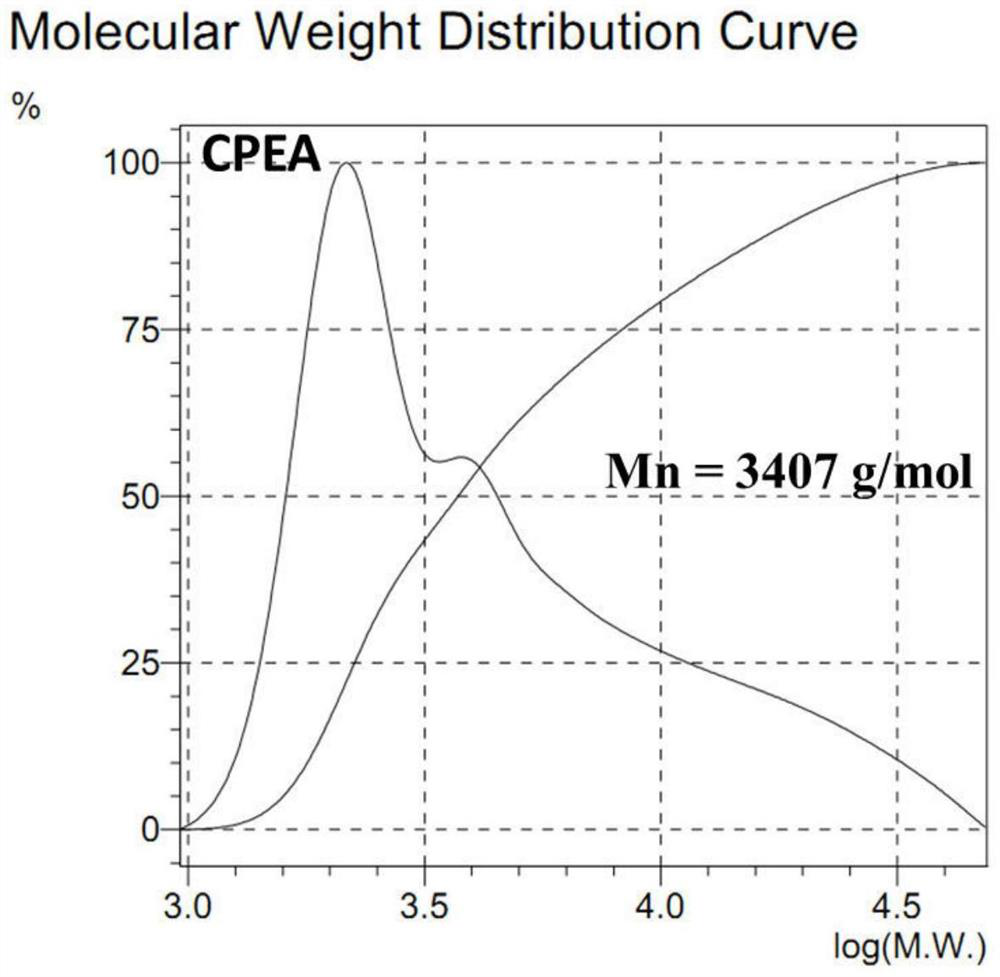

[0038]2) Synthesis o...

Embodiment 2

[0041] Utilize the cardanol polyoxyethylene ether in embodiment 1, synthesize cardanol polyoxyethylene ether n-butyl ester, the process is as follows: 110g above-mentioned cardanol polyoxyethylene ether; 8.0g n-butyric acid, 3.3g p-toluenesulfonic acid, 33.0 g of cyclohexane was added to the four-necked flask, and the reaction was terminated after 8 h at 82-105 °C. Excess cyclohexane was removed by distillation under reduced pressure, followed by 10 wt% NaHCO 3 The solution washes the remaining liquid until the pH of the system becomes neutral; finally, it is dehydrated and dried by distillation under reduced pressure to obtain cardanol polyoxyethylene ether n-butyrate (CPEB). Figure 4 shown; GPC results are shown in Figure 5 As shown, the number average molecular weight Mn was 3813 g / mol.

Embodiment 3

[0043] Utilize the cardanol polyoxyethylene ether in Example 1 to synthesize cardanol polyoxyethylene ether oleate, and the process is as follows: 80 g of the above-mentioned cardanol polyoxyethylene ether; 20.2 g of oleic acid, 0.8 g of p-toluenesulfonic acid, 32.0 g of g-cyclohexane was added to the four-necked flask, and the reaction was terminated after 7 h at 93-105 °C. Excess cyclohexane was removed by distillation under reduced pressure, followed by 10 wt% NaHCO 3 The solution washes the remaining liquid until the pH of the system becomes neutral; finally, it is dehydrated and dried by distillation under reduced pressure to obtain cardanol polyoxyethylene ether oleate (CPEO). Image 6 shown; GPC results are shown in Figure 7 As shown, the number average molecular weight Mn was 4113 g / mol.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com