Method for producing adenine through fermentation

A technique for producing adenine and bacteria, which is applied in the field of fermentation and production of adenine, and can solve problems such as difficulty in extracting adenine

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

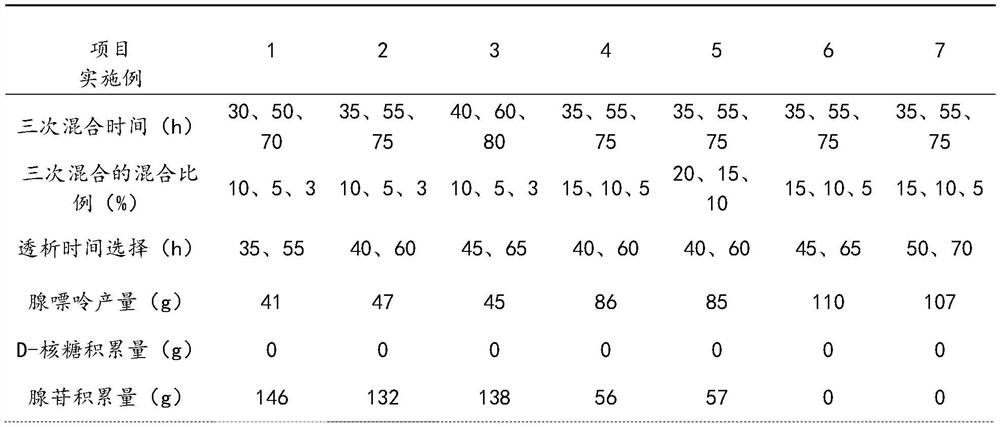

Examples

Embodiment 1

[0031] A method for producing adenine by fermentation, the concrete steps are as follows:

[0032] 1. Bacillus subtilis XGL culture

[0033] (1) Activation of strains: Bacillus subtilis XGL was inserted into the slanted medium from the glycerol storage tube for activation and cultivation (two generations of activation), and the temperature was maintained at 34 ° C; the composition and content of the slanted medium were: glucose 2g / L, beef extract 10g / L, sodium chloride 2.5g / L, peptone 10g / L, yeast powder 2g / L, agar powder 25g / L, xanthine 50mg / L, histidine 50mg / L;

[0034] (2) Seed culture (2L): Pour about 200 mL of sterile water into the above-mentioned eggplant-shaped bottle near the flame of the ultra-clean bench, scrape the colonies into sterile water with an inoculating ring and disperse to prepare a bacterial suspension, and place in a fermenter. The bacterial suspension is inoculated into the fermented seed culture tank beside the fire ring. During the cultivation proc...

Embodiment 2

[0046] A method for producing adenine by fermentation, with reference to Example 1, the difference is: the time of three mixing operations is selected as 35h, 55h and 75h respectively;

[0047] When the fermentation was put in the tank for 85 hours, the total adenosine amount was 132 g, the total adenine production was 47 g, and the total D-ribose production was 0 g.

Embodiment 3

[0049] A method for producing adenine by fermentation, with reference to Example 1, the difference is: the time of the three mixing operations is selected as 40h, 60h and 80h respectively;

[0050] When the fermentation was put in the tank for 85 hours, the total adenosine amount was 138 g, the total adenine production was 45 g, and the total D-ribose production was 0 g.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com