Electrostatic spinning process for preparing sulfonated polymer elastomer nanofiber membrane

An electrospinning process, a polymer elastomer technology, applied in the chemical characteristics of fibers, single-component synthetic polymer rayon, textiles and papermaking, etc., can solve the problems of poor film air permeability and small adjustable range of microstructure, etc. Achieving the effects of good dimensional stability, wide adjustable range of morphology and excellent mechanical properties

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

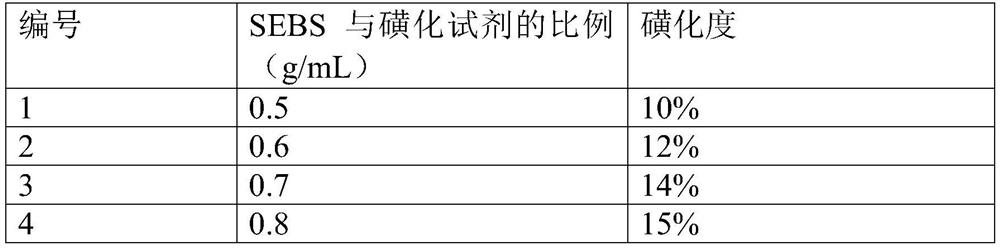

[0025] The preparation method of sulfonated SEBS is as follows:

[0026] (1) Preparation of sulfonation reagent

[0027] First, acetic anhydride and 1,2-dichloroethane were mixed, and concentrated sulfuric acid was added dropwise with stirring in an ice-water bath, then stirred in an ice-water bath for 30 minutes, and then vigorously stirred at room temperature for 10 minutes to obtain a sulfonated reagent. During the operation, the molar ratio of acetic anhydride and concentrated sulfuric acid was controlled to be 1.5:1, and the volume ratio of acetic anhydride to 1,2-dichloroethane was 1:15.

[0028] (2) Preparation of sulfonated SEBS

[0029] Get 5g SEBS and add 150mL mixed solvent of 1.2-dichloroethane and cyclohexane (wherein the volume ratio of 1.2-dichloroethane and cyclohexane is 5:1), stir and dissolve at 50 ℃ to obtain SEBS solution, Then, the above-mentioned sulfonating reagent was added dropwise to the SEBS solution, reacted at 50°C for 5 hours, isopropanol was a...

Embodiment 1-15

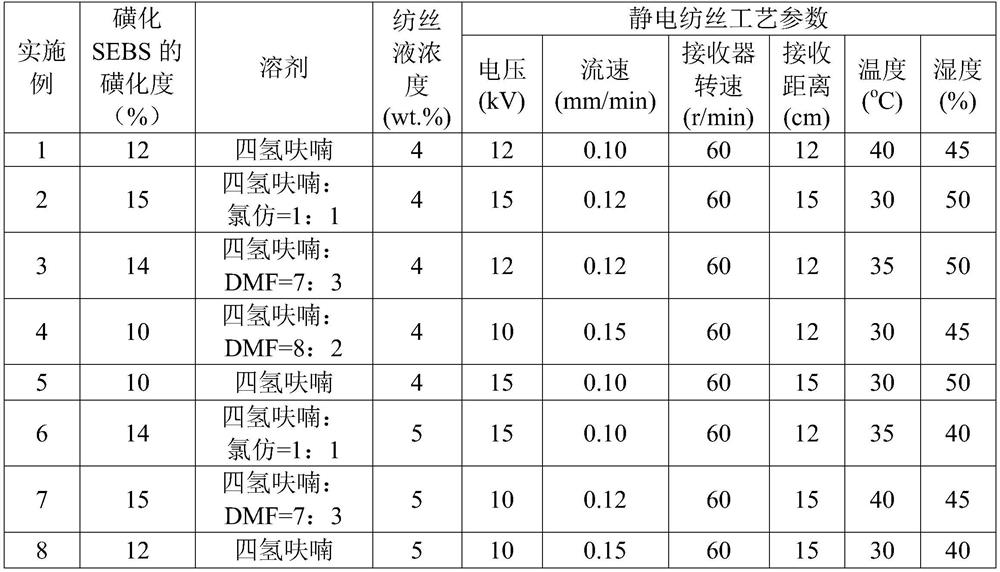

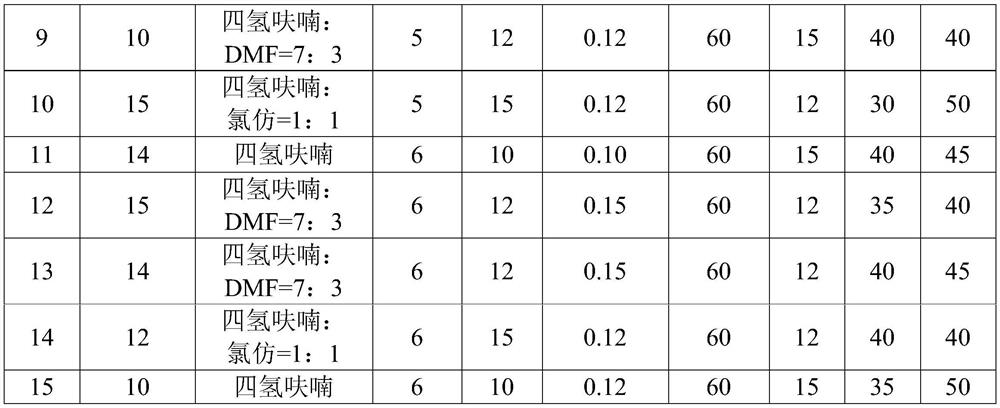

[0033] Examples 1-15: Electrospinning Process for Preparation of Sulfonated SEBS Nanofibrous Membranes

[0034] (1) according to table 2, take by weighing sulfonated SEBS and be dissolved in solvent and be made into the spinning solution of corresponding concentration;

[0035] (2) electrospinning the spinning solution to obtain a nanofiber membrane, and the electrospinning process parameters are shown in Table 2;

[0036] (3) The sulfonated SEBS nanofiber membrane is obtained after the nanofiber membrane is vacuum-dried.

[0037] Table 2. Sulfonated SEBS nanofiber membranes under different formulations and electrospinning processes

[0038]

[0039]

[0040] The beneficial effects of the present invention are demonstrated below through experimental examples.

experiment example 1

[0041] Experimental Example 1: Performance characterization of the sulfonated SEBS nanofiber membrane obtained in the present invention

[0042] 1. Test sample

[0043] Sulfonated SEBS nanofiber membranes prepared in Examples 1-15.

[0044] 2. Experimental method

[0045] Air permeability test method: refer to GB / T1038-2000;

[0046] Tensile strength test method: refer to GB3923.1-2013.

[0047] 3. Experimental results

[0048] Table 3. Performance characterization results of each sulfonated SEBS nanofiber membrane

[0049] Example Air permeability (mm s -1 )

Tensile strength (MPa) 1 167 2.97 2 158 3.27 3 160 3.37 4 148 3.12 5 159 2.87 6 197 4.67 7 193 4.76 8 225 5.14 9 198 4.98 10 200 4.86 11 204 4.79 12 206 4.74 13 197 4.89 14 208 4.96 15 210 5.02

[0050] It can be seen that the air permeability of the sulfonated SEBS nanofiber membranes prepared in Examples 1...

PUM

| Property | Measurement | Unit |

|---|---|---|

| strength | aaaaa | aaaaa |

| Degree of sulfonation | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com