Environment-friendly explosion-proof modified ultra-high molecular weight polyethylene fiber and preparation method thereof

A technology of ultra-high molecular weight and polyethylene fibers, which is applied in fiber types, fiber processing, textiles and papermaking, etc. It can solve the problems of fiber mechanical property damage, damaged fiber mechanical properties, and damaged fiber self-strength, etc., to improve interface adhesion properties, nucleation and growth promotion, strength and toughness enhancement effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

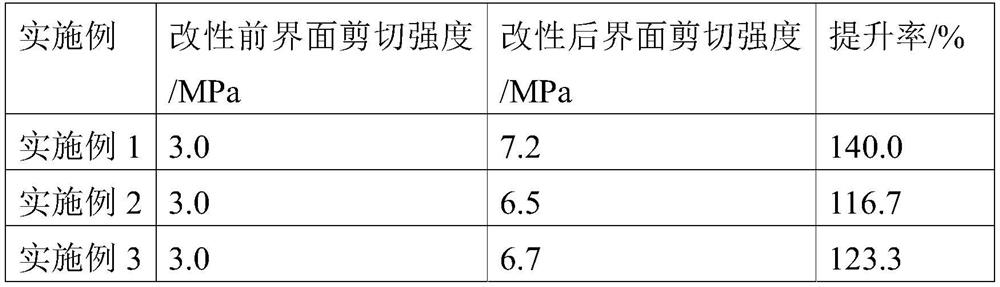

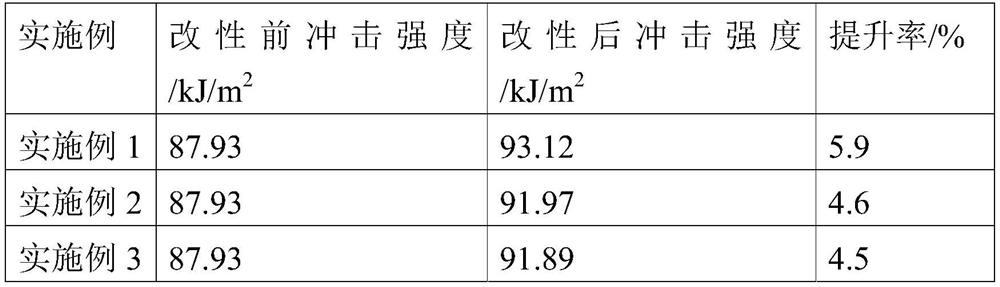

Examples

Embodiment 1

[0024] A preparation method of a modified ultra-high molecular weight polyethylene fiber for environmental protection and explosion-proof use, the preparation method comprises the following steps:

[0025] (1) soak the ultra-high molecular weight polyethylene fiber in absolute ethanol for ultrasonic cleaning, take out and dry; then soak in tannic acid buffer solution (the concentration of tannic acid is 2g / L, and the concentration of sodium chloride is 15g / L , pH 7 tris(hydroxymethylaminomethane buffer), placed in a shaker at 25°C, and reacted for 6h at a shaking rate of 60r / min; finally, the pretreated ultra-high molecular weight was obtained after washing and drying. polyethylene fibers;

[0026] (2) In the deionized aqueous solution containing 1.6g / L zinc acetate dihydrate and 0.07g / L cetyltrimethylammonium bromide, add NaOH to adjust pH to 11, and then add the pretreatment obtained in step (1) The ultra-high molecular weight polyethylene fiber was ultrasonicated for 1 hou...

Embodiment 2

[0028] A preparation method of a modified ultra-high molecular weight polyethylene fiber for environmental protection and explosion-proof use, the preparation method comprises the following steps:

[0029] (1) soak the ultra-high molecular weight polyethylene fiber in absolute ethanol for ultrasonic cleaning, take out and dry; then soak in tannic acid buffer solution (the concentration of tannic acid is 0.5g / L, the concentration of sodium chloride is 15g / L) L, tris(hydroxymethylaminomethane buffer solution with pH 8), placed in a shaker at 25°C, and the shaking rate was 120r / min to react for 2h; after final cleaning and drying, the pretreated ultra-high Molecular weight polyethylene fibers;

[0030] (2) in the deionized aqueous solution containing 1.02g / L zinc acetate dihydrate and 0.01g / L cetyltrimethylammonium bromide, add NaOH to adjust pH to 9, then add the pretreatment obtained in step (1) The ultra-high molecular weight polyethylene fiber of 80 ° C, the power is 80 kHz,...

Embodiment 3

[0032] A preparation method of a modified ultra-high molecular weight polyethylene fiber for environmental protection and explosion-proof use, the preparation method comprises the following steps:

[0033] (1) soak the ultra-high molecular weight polyethylene fiber in absolute ethanol for ultrasonic cleaning, take out and dry; then soak in tannic acid buffer solution (the concentration of tannic acid is 4g / L, the concentration of sodium chloride is 15g / L , tris(hydroxymethylaminomethane buffer solution with pH 9), placed in a shaker at 25°C, and reacted for 8h under the condition of a shaking rate of 100r / min; finally, the pretreated ultra-high molecular weight was obtained after washing and drying. polyethylene fibers;

[0034] (2) in the deionized aqueous solution containing 2g / L zinc acetate dihydrate and 0.05g / L cetyltrimethylammonium bromide, add NaOH to adjust pH to 13, then add the pretreated Ultra-high molecular weight polyethylene fiber, sonicated for 1 hour at 80°C ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com