Structural color fiber material and preparation method thereof

A fiber material and structural color technology, applied in the field of fiber materials, can solve problems such as the surface shedding of textile substrates, cracks in the photonic crystal structure, and great influence on textile substrates, so as to achieve bright colors, avoid uneven color development, and facilitate adsorption Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0037] A preparation method of the structural color fiber material of any one of the above, comprising the following steps:

[0038] S1. Mix the two-dimensional material MXene with the dispersion liquid to obtain a two-dimensional material MXene solution with a concentration of 0.1-50 mg / mL; mix the photonic crystal nano-microspheres with the dispersion liquid to obtain a concentration of 0.01-1.0 g / mL Photonic crystal nano-microsphere solution;

[0039] S2, using a high-pressure airflow spray gun to uniformly spray the two-dimensional material MXene solution on the surface of the fiber material substrate to obtain MXene / fiber material substrate;

[0040] S3, spraying the photonic crystal nano-microsphere solution on the surface of the MXene / fiber material substrate obtained in step S2, and drying at 50-80° C. to obtain a structural color fiber material.

[0041] Wherein, the dispersion liquid is composed of one or more of alcohol solvent and deionized water. After the two-d...

Embodiment 1

[0046] The present embodiment provides a structural color fiber material and a preparation method thereof, comprising the following steps:

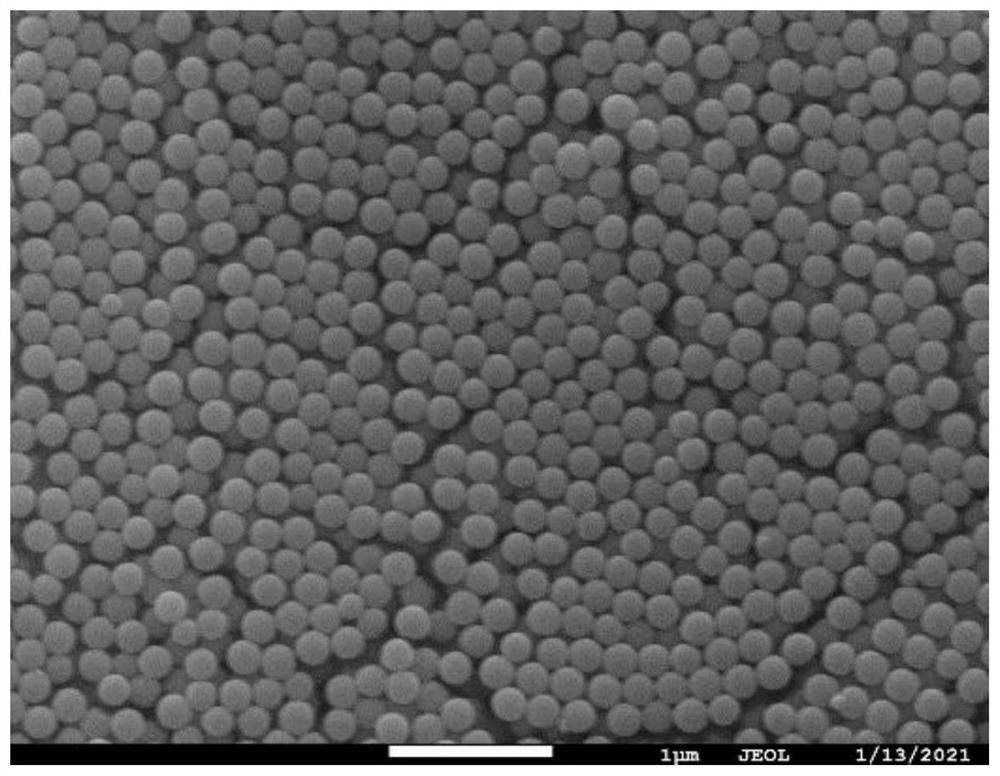

[0047] S1. Using ethyl orthosilicate with a concentration of 3.5% as a silicon source, ammonia water as a catalyst, a mixed solution of water and ethanol as a solvent, the reaction temperature is 40 ° C, and the reaction time is 2 h, the prepared silica colloidal nano-microspheres are as follows: Centrifuge at 1100 rpm, wash and purify, and dry at 60 °C to obtain silica colloidal nano-microspheres with a particle size of 164 nm;

[0048] S2, mixing the two-dimensional material MXene with an average sheet diameter of 5 μm and the dispersion to obtain a two-dimensional material MXene solution with a concentration of 10 mg / mL; mixing the silica colloidal nano-microsphere powder obtained in step S1 with the dispersion, A silica colloidal nano-microsphere solution with a concentration of 0.04 g / mL was prepared;

[0049] S3, using a high-press...

Embodiment 2~4

[0059] This example provides a structural color fiber material and a preparation method thereof. Compared with Example 1, the difference is that the particle sizes of the prepared silica colloidal nano-microspheres are 220 nm, 255 nm, and 341 nm, respectively; It is roughly the same as Embodiment 1, and will not be repeated here.

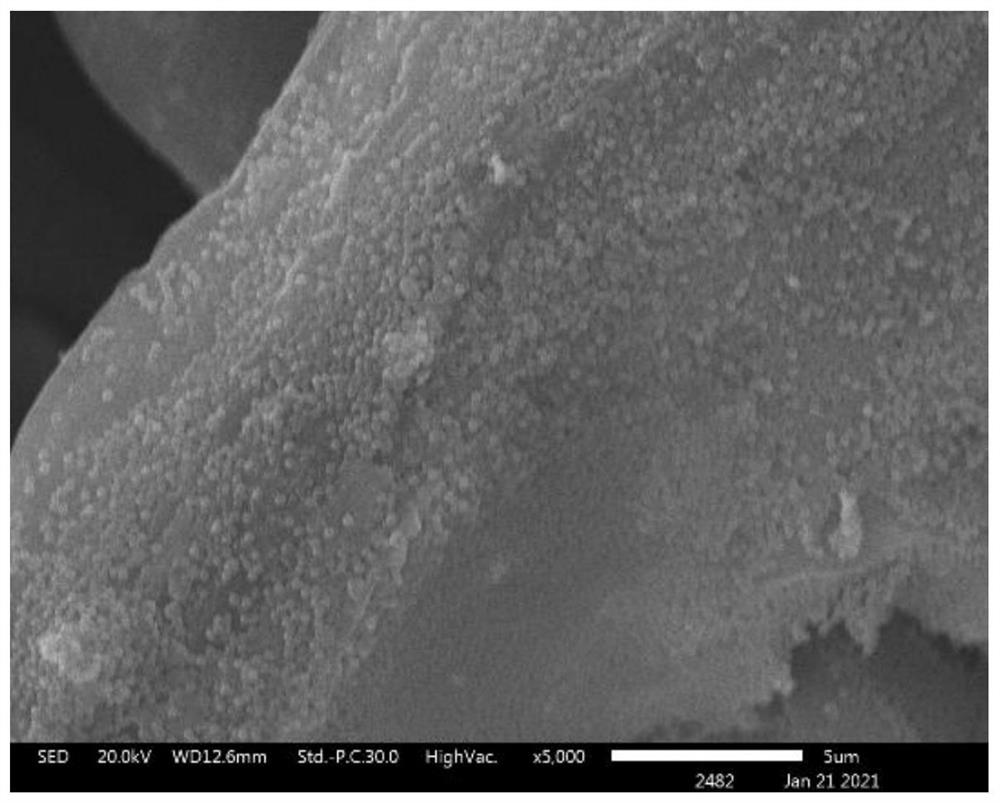

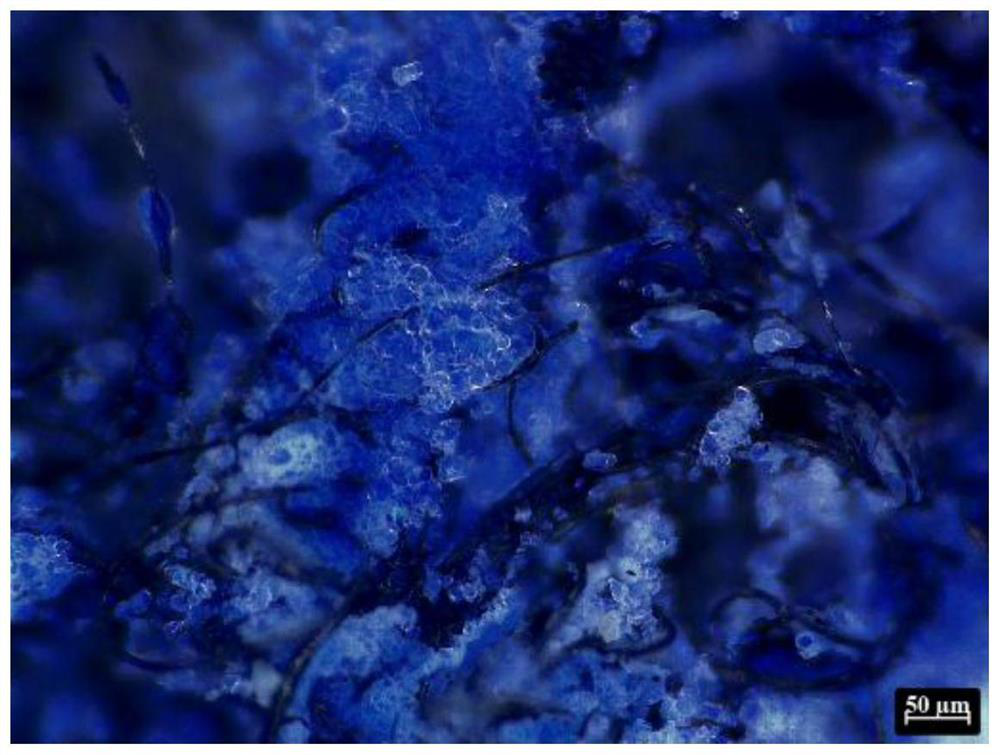

[0060] see Figure 4 shown, Figure 4 The appearance diagram of the original PET / PA non-woven fabric, the structural color PET / PA orange-shaped microfiber non-woven fabric prepared in Comparative Example 1 and Examples 1 to 4, it can be seen from the figure that the photonic crystal nano-microspheres The adhesion on the surface of the non-woven fabric is very firm and uniform, and the color rendering effect is also very uniform; and the non-woven fabric prepared by silica colloidal nano-microspheres with different particle sizes has different colors; this is because the photonic crystals of different sizes are sensitive to light. Different effects...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| concentration | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com