Production process and fermentation device of flavor enhancer

A production process and fermentation device technology, applied in the field of the umami agent production process and its fermentation device, can solve the problems of time-consuming and laborious, loss of mellow taste, etc., and achieve the effects of avoiding too many dead ends, improving immunity, and strong taste penetration.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

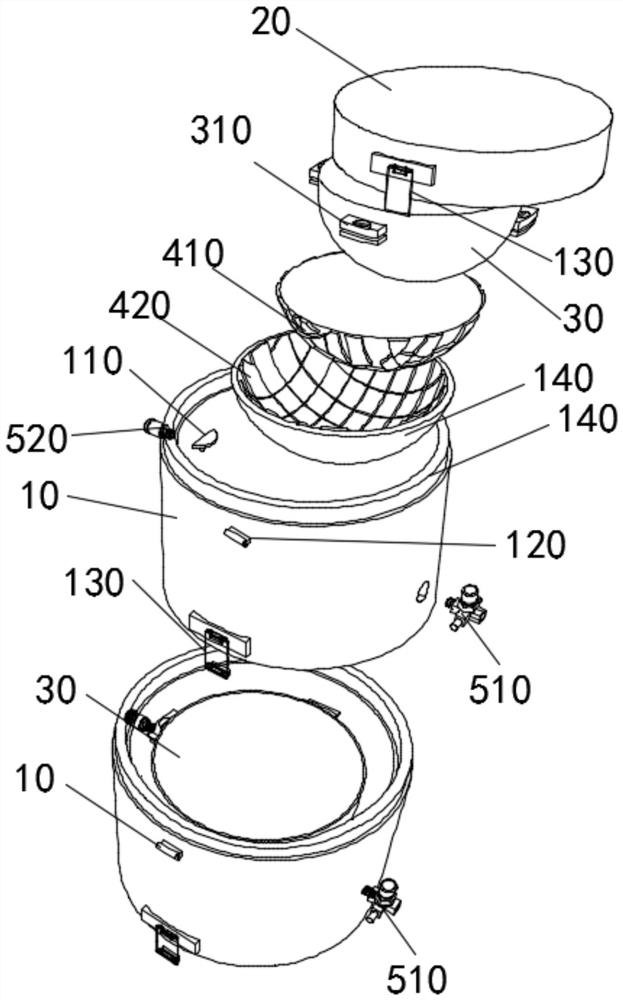

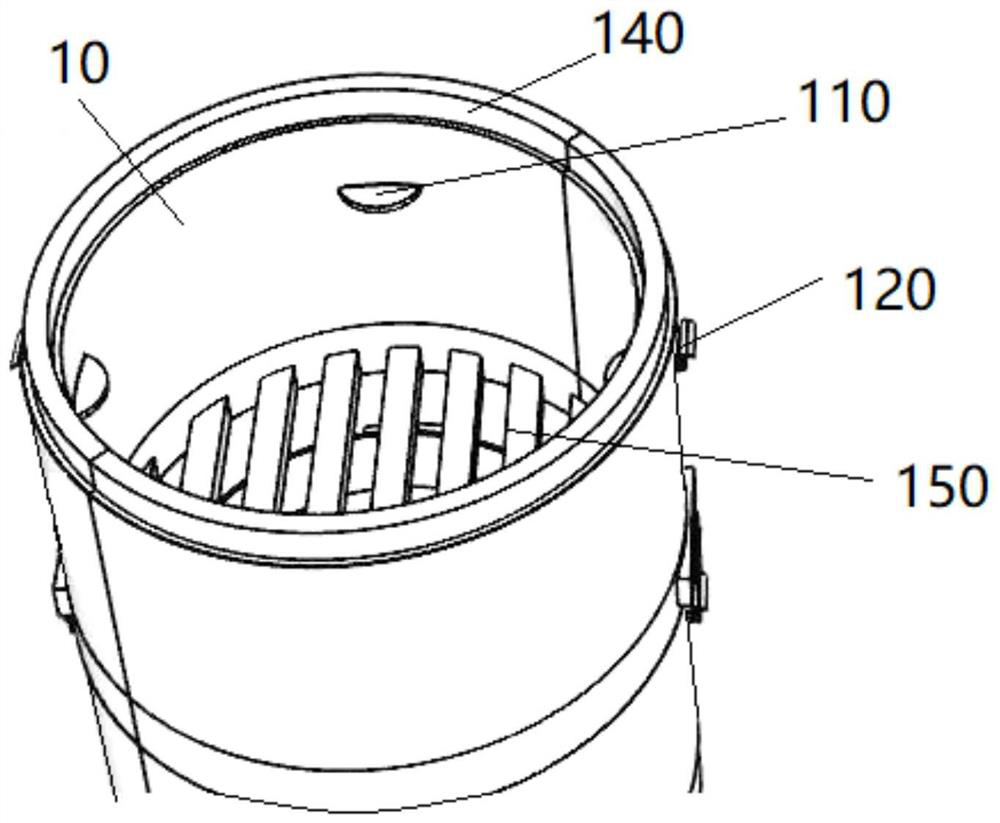

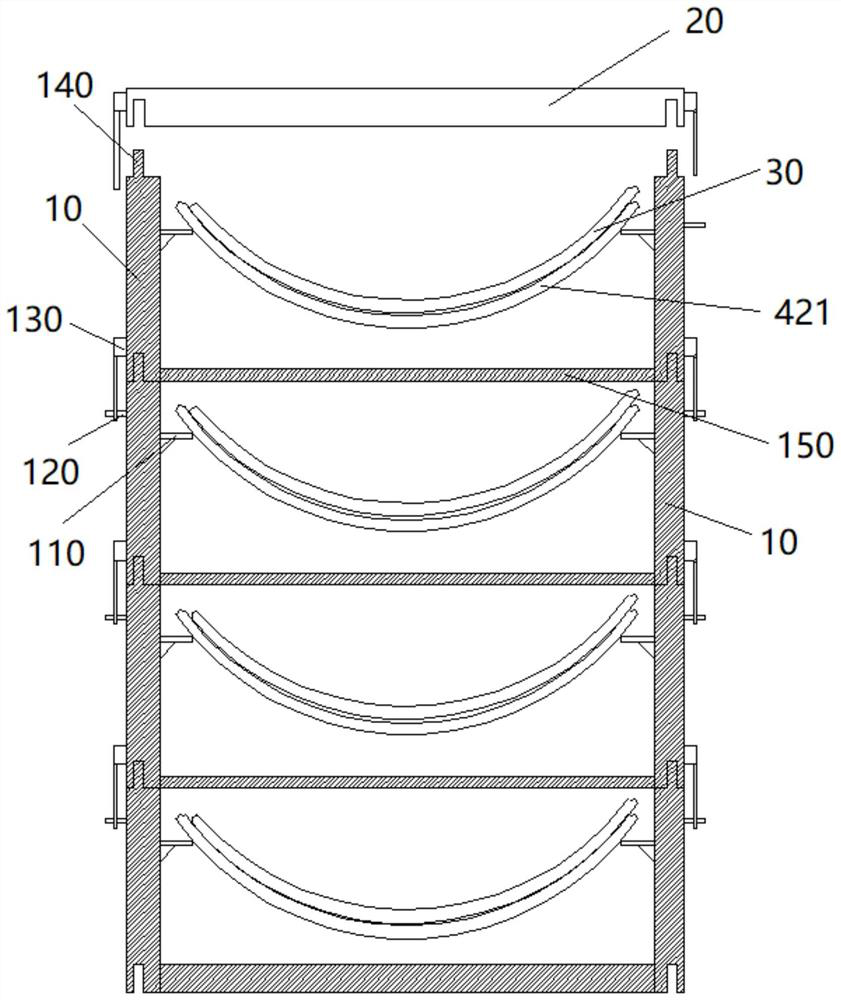

Image

Examples

Embodiment 1

[0034] A production process for an umami agent, comprising the following steps:

[0035] S1: Chicken Powder Preparation:

[0036] Choose fresh chicken or chicken breast, soak and wash it, soak it in water for 40 minutes, remove the blood water, boil the fresh chicken or chicken breast in water, remove the foam on the surface, and boil for 20 minutes. If it is fresh chicken, you need to remove the chicken skin and remove the chicken bones, then put the chicken in the soup and continue to cook, and the chicken breast can be simmered continuously. Mix the onion, ginger, salt, sugar, and pepper into powder, then Continue to cook for 30 minutes, grind the stewed chicken or chicken breast into powder through a grinder, and bake until the moisture is between 7-12% to obtain chicken powder for later use, in which the chicken oil and the clear soup are separated in the boiled chicken soup. spare;

[0037] S3: Fermentation enzymatic hydrolysis

[0038] The chicken powder is mixed wit...

Embodiment 2

[0046] Specifically, the chicken powder, water, clear soup, chicken oil, edible salt and mushroom enzyme in S4 are in proportions of 1.5:9.0:3.5:2.5:0.1:0.25 parts by weight;

[0047]Specifically in this embodiment, the mushroom enzyme described in step S2 is a mixture of black fungus, pine mushrooms, shiitake mushrooms, brown sugar, and probiotics in a weight ratio of 0.5:1:1.5:3:2. Add 4-6 times the mass of water to make a slurry, and after fermentation, the mushroom enzyme is obtained, the fermentation temperature is 35-40° C., and the fermentation time is 24-48h.

Embodiment 3

[0049] Different from embodiment one has the following points, wherein the production process of this umami agent concrete agent is as follows:

[0050] 1. The preparation of chicken powder in S1 starts from the crushing process: crushing-mixing-granulating-drying-screening-finished product.

[0051] Crushing, mixing, granulating and drying are the four major steps in the production of umami.

[0052] The drying equipment involved is the main equipment, but it is also inseparable from many auxiliary equipment, such as: screening, packaging, heating system, conveying system, etc.

[0053] 1. Chicken powder starts from fresh chicken and has a second treatment method, which is suitable for mass production and improves the umami taste through enzymatic hydrolysis, but it is a pure liquid umami agent and can be used as food ingredients. The processing steps are as follows: fresh chicken—flavoring—cooking—colloid mill—enzymolysis—colloid mill—filtering—spraying—chicken powder.

[...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com