Phosphoric acid modified silicon dioxide microspheres as well as preparation method and application thereof

A silica and microsphere technology, applied in the field of water treatment, can solve the problems of low chemical and thermal stability, poor recycling performance, slow adsorption kinetics, etc., and achieve the effects of simple preparation method, few steps, and efficient synthesis

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

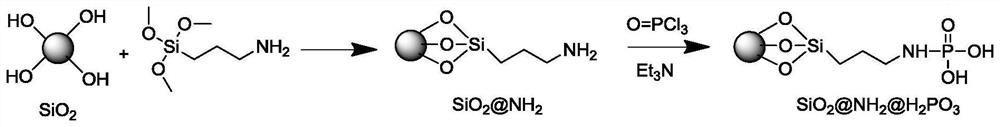

[0046] Example 1 Preparation of phosphoric acid modified silica microsphere material

[0047] 1) Disperse 6.2 g of silica microspheres in 70 mL of anhydrous toluene under the action of ultrasound, add 4 mL of 3-aminopropyltrimethoxysilane dropwise, and reflux the final mixture in an oil bath at 103 °C for 24 h, take out the The silica microspheres were washed with absolute ethanol, and then dried in a vacuum drying oven at 80 °C for 24 h to obtain 3-aminopropyl-functionalized silica microspheres (SiO 2 @NH 2 );

[0048] 2) Take 2g SiO 2 @NH 2 It was dispersed into 70 mL of acetonitrile under the action of ultrasound, and then 16 mL of triethylamine was added, and then 6 mL of phosphorus oxychloride was slowly added dropwise to it, and the reaction was carried out in an oil bath at 40 °C for 24 h. Then it was dried in a vacuum drying oven at 80°C for 24 hours to obtain phosphoric acid modified silica microspheres (SiO 2 @NH 2 @H 2 PO 3 ).

Embodiment 2

[0049] Example 2 Preparation of phosphoric acid modified silica microsphere material

[0050] 1) Disperse 5 g of silica microspheres in 30 mL of anhydrous toluene under the action of ultrasound, add 4 mL of 3-aminopropyltrimethoxysilane dropwise, and reflux the final mixture in an oil bath at 103 °C for 24 h, take out the dioxide The silicon microspheres were washed with absolute ethanol, and then dried in a vacuum drying oven at 80 °C for 24 h to obtain 3-aminopropyl functionalized silica microspheres (SiO 2 @NH 2 );

[0051] 2) Take 1g SiO 2 @NH 2 Disperse into 30 mL of acetonitrile under the action of ultrasound, then add 16 mL of triethylamine, then slowly dropwise add 6 mL of phosphorus oxychloride to it, react in an oil bath at 40 °C for 24 h, and wash the product with acetonitrile, water, and anhydrous ethanol in turn, Then it was dried in a vacuum drying oven at 80°C for 24 hours to obtain phosphoric acid modified silica microspheres (SiO 2 @NH 2 @H 2 PO 3 ). ...

Embodiment 3

[0052] Example 3 Preparation of phosphoric acid modified silica microsphere material

[0053] 1) Disperse 10 g of silica microspheres in 100 mL of anhydrous toluene under the action of ultrasound, add 4 mL of 3-aminopropyltrimethoxysilane dropwise, and reflux the final mixture in an oil bath at 103 °C for 24 hours, take out the dioxide The silicon microspheres were washed with absolute ethanol, and then dried in a vacuum drying oven at 80 °C for 24 h to obtain 3-aminopropyl functionalized silica microspheres (SiO 2 @NH 2 );

[0054] 2) Take 2g SiO 2 @NH 2 Disperse into 50 mL of acetonitrile under the action of ultrasound, then add 16 mL of triethylamine, and then slowly add 6 mL of phosphorus oxychloride dropwise to it, react in an oil bath at 40 °C for 24 h, and wash the product with acetonitrile, water, and absolute ethanol in turn. Then it was dried in a vacuum drying oven at 80°C for 24 hours to obtain phosphoric acid modified silica microspheres (SiO 2 @NH 2 @H 2 P...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| pore size | aaaaa | aaaaa |

| specific surface area | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com