Activated carbon encapsulated imidazole metal organic framework composite material with high gas separation selectivity and preparation method of activated carbon encapsulated imidazole metal organic framework composite material

A metal-organic framework and composite material technology, which is applied in the field of activated carbon-encapsulated imidazole-based metal-organic framework composite materials and its preparation, can solve the problems of no selective adsorption capacity, disordered pore structure, and high manufacturing cost, so as to improve selectivity and Effects of adsorption amount, increasing types of functional groups, and increasing micropore content

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

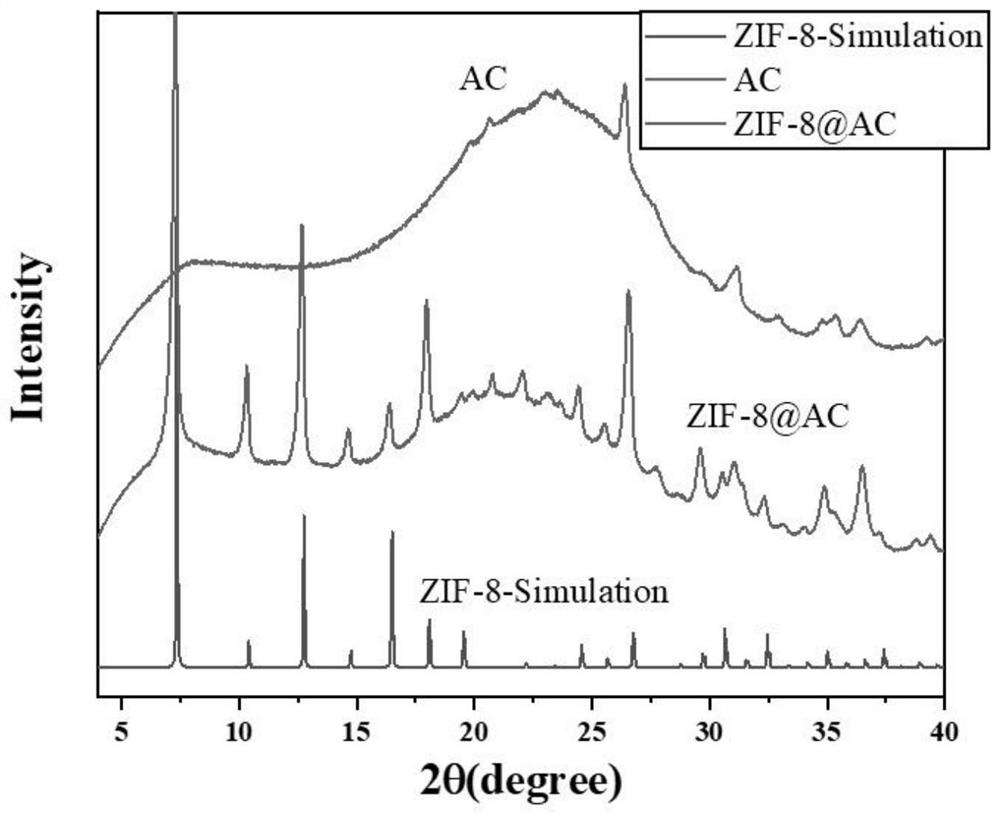

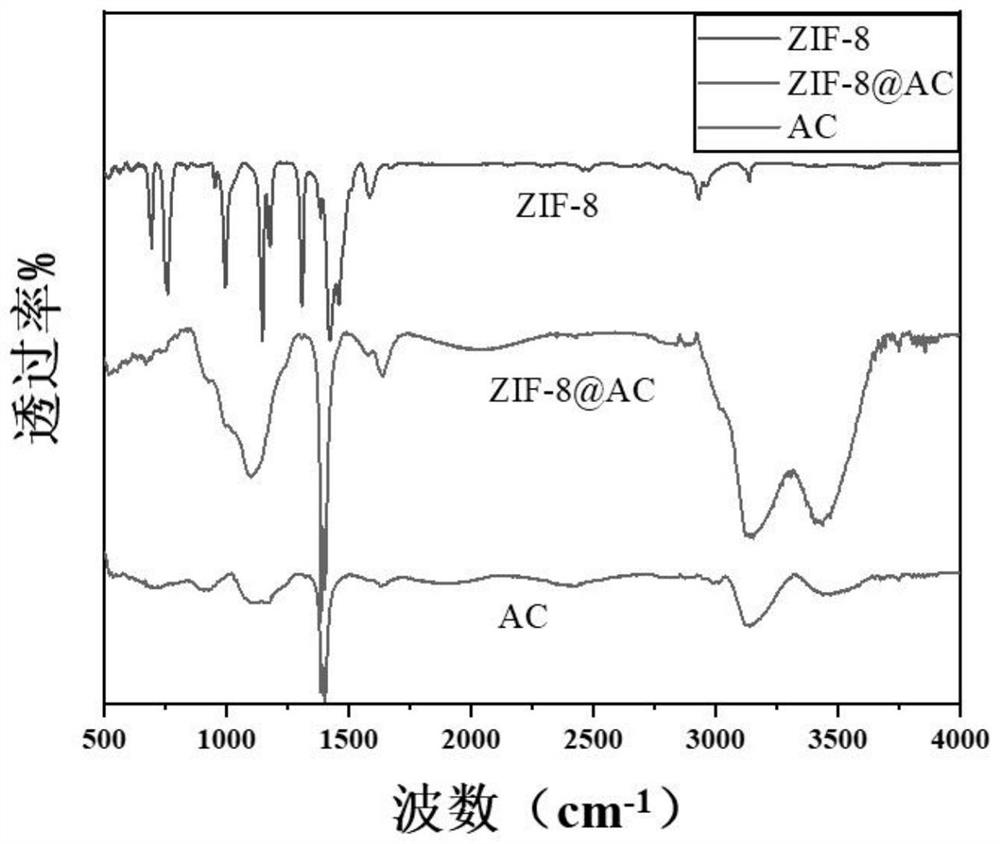

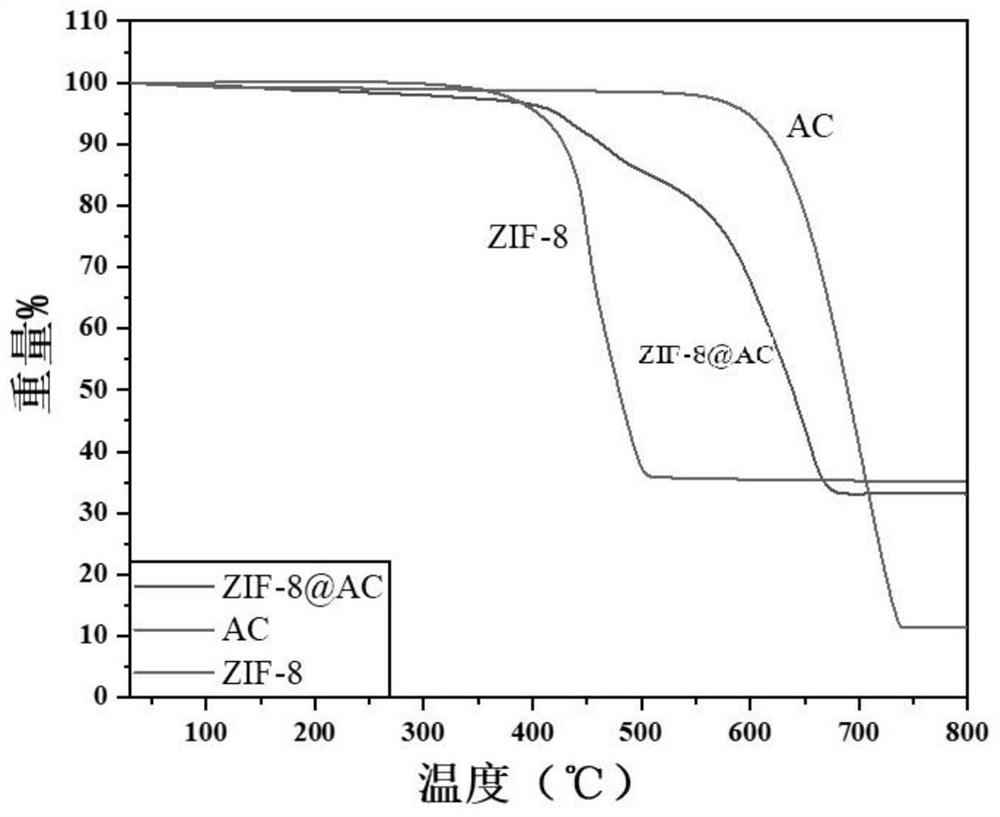

[0042] Example 1 Activated carbon encapsulated imidazole ZIF-8 metal-organic framework composite material (ZIF-8@AC composite carbon material) and its preparation method

[0043] The structural formula of the ZIF-8@AC composite carbon material is: AC 108 ·(C 8 H 10 N 4 Zn) 1 , AC = activated carbon, AC = 85wt%, C 8 H 10 N 4 Zn=15wt%. The preparation method of the ZIF-8@AC composite carbon material includes the following steps:

[0044] (1) Preparation of reaction solvent

[0045] Add 0.83g of zinc nitrate hexahydrate to 10mL of methanol, stir at room temperature until dissolved to make zinc nitrate methanol solution; add 0.65g of 2-methylimidazole to 10mL of methanol and stir until dissolved to make 2-methylimidazole. methanol solution.

[0046] (2) Preparation of ZIF-8@AC composite carbon materials

[0047] First, columnar activated carbon WS-480 (diameter about 3-4mm, BET specific surface reaches 1137m 2 / g) Soak in zinc nitrate methanol solution for 30min, and s...

Embodiment 2

[0048] Example 2 Activated carbon encapsulated imidazole ZIF-8 metal-organic framework composite material (ZIF-8@AC composite carbon material) and its preparation method

[0049] The structural formula of the ZIF-8@AC composite carbon material is: AC 76 ·(C 8 H 10 N 4 Zn) 1 , AC = activated carbon, AC = 80wt%, C 8 H 10 N 4 Zn=20wt%. The preparation method of the ZIF-8@AC composite carbon material includes the following steps:

[0050] (1) Preparation of reaction solvent

[0051] 0.65g of 2-methylimidazole was added to 10mL of methanol and stirred until dissolved to make a methanol solution of 2-methylimidazole; 1.5g of zinc nitrate hexahydrate was heated to a molten state.

[0052] (2) Preparation of ZIF-8@AC composite carbon materials

[0053] First, columnar activated carbon WS-480 (diameter about 3-4mm, BET specific surface reaches 1137m 2 / g) placed in molten zinc nitrate hexahydrate, soaked in ultrasonic for 30 min, and then placed the activated carbon adsorbed...

Embodiment 3

[0054] Example 3 Activated carbon encapsulated imidazole ZIF-8 metal-organic framework composite material (ZIF-8@AC composite carbon material) and its preparation method

[0055] The structural formula of the ZIF-8@AC composite carbon material is: AC 108 ·(C 8 H 10 N 4 Zn) 1 , AC = activated carbon, AC = 85wt%, C 8 H 10 N 4 Zn=15wt%. The preparation method of the ZIF-8@AC composite carbon material includes the following steps:

[0056] (1) Preparation of reaction solvent

[0057] Add 0.6g of zinc chloride and 0.3g of sodium formate to 20mL of methanol, stir to dissolve at room temperature to make methanol solution of zinc chloride and sodium formate; add 0.5g of 2-methylimidazole to 10mL of methanol and stir until dissolved. A methanol solution of 2-methylimidazole was obtained.

[0058] (2) Preparation of ZIF-8@AC composite carbon materials

[0059] First, columnar activated carbon WS-480 (diameter about 3-4mm, BET specific surface reaches 1137m 2 / g) soaked in me...

PUM

| Property | Measurement | Unit |

|---|---|---|

| concentration | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com