Preparation method and application of TiO2-C-MoO2 nano composite material

A nanocomposite material, tio2-c-moo2 technology, applied in chemical instruments and methods, metal/metal oxide/metal hydroxide catalysts, hydrogen production, etc., can solve the problem of low conductivity of composite materials and limited heterogeneity Combining the problems of material performance and process complexity, etc., to achieve the effect of fine particle size, reduction of energy consumption and reaction cost, and uniform distribution

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0023] Mix 2 g of P25, 1 g of citric acid and x g of ammonium molybdate (x = 0.5, 1, 1.5) evenly, then keep the mixed powder at 200 °C for 1 h in an Ar atmosphere, and then heat to 800℃ for 2h to obtain TiO 2 -C-MoO 2 Nanocomposite, three samples are labeled TCM 2:1:0.5, TCM 2:1:1, TCM 2:1:1.5. For comparison, the samples obtained with 0 amount of ammonium molybdate are labeled as TiO 2 -C.

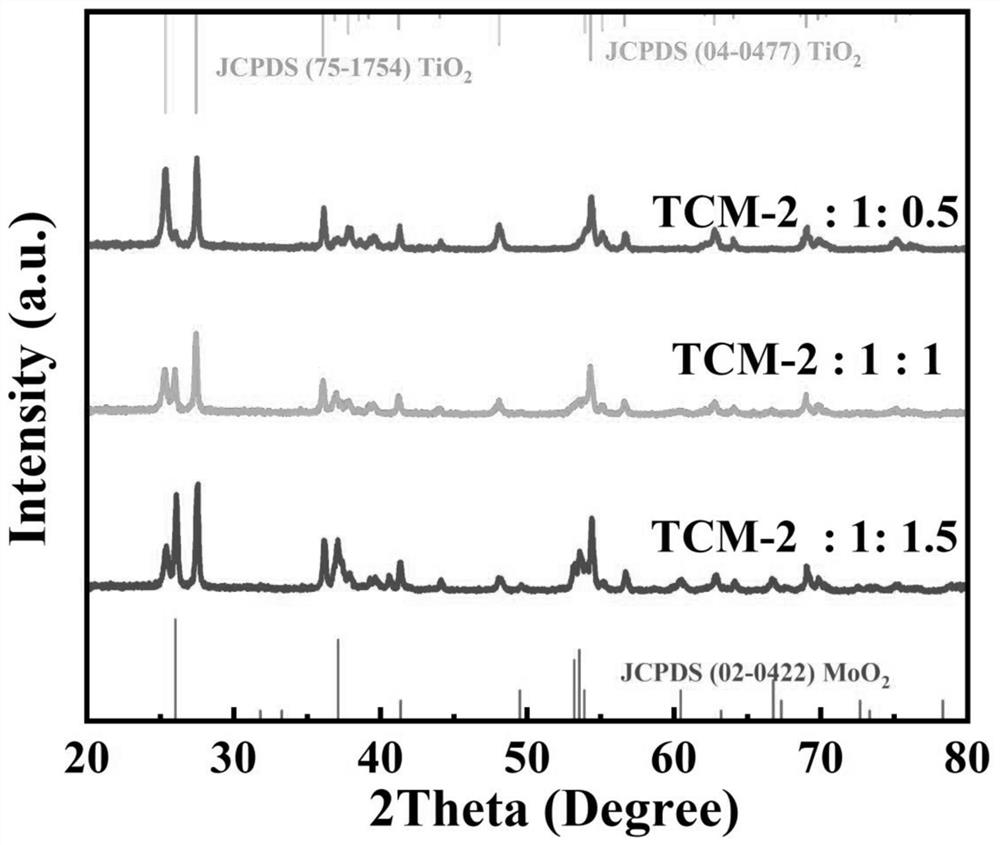

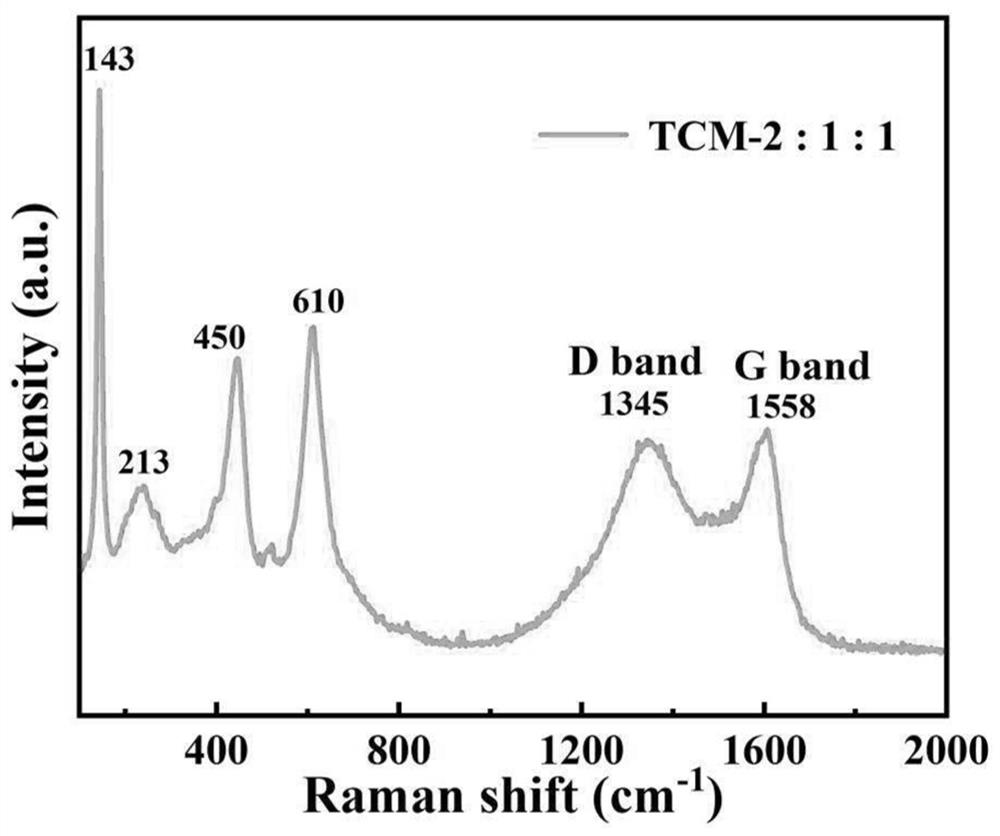

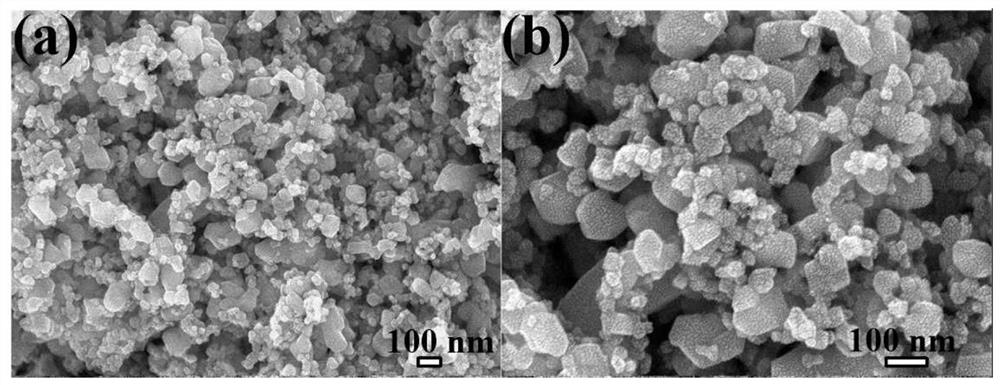

[0024] TiO prepared above 2 -C-MoO 2 The XRD pattern of the nanocomposite is as follows: figure 1 shown, with the standard sample TiO 2 with MoO 2 The comparative analysis of XRD diffraction peaks found that the composite nanomaterials contained TiO 2 and MoO 2 nanoparticles. Raman spectroscopy analysis of TCM 2:1:1 samples ( figure 2 ) showed that the nanocomposites contained amorphous carbon. SEM of TCM 2:1:1 samples as image 3 shown, from image 3 a and its magnification image 3 b It can be seen that the composite nanomaterials are nano-sized, and the particle size d...

Embodiment 2

[0027]Mix 2 g of P25, x g of citric acid (x = 0, 0.5, 1, 1.5) with 1 g of ammonium molybdate, and then keep the mixed powder at 150 °C for 1 h in an Ar atmosphere. Then heated to 820 °C for 2 h to obtain nanocomposite materials. When the content of citric acid is 0, the obtained product is TiO 2 -MoO 2 Nanocomposite material, after adding citric acid, the Raman spectrum peak of C appeared in the product, which proved that TiO was formed 2 -C-MoO 2 Nanocomposites.

[0028] Take 20 mg of the above-prepared nanocomposite material for photocatalytic hydrogen production test, and the test process is the same as that in Example 1. When the content of citric acid is 0, the obtained TiO 2 -MoO 2 The photocatalytic hydrogen production activity of the nanocomposite is close to P25, which is basically 0, while TiO 2 -C-MoO 2 The photocatalytic hydrogen production activity of the nanocomposites was significantly improved. When the mass of citric acid was 0.5, 1, and 1.5, the hydro...

Embodiment 3

[0030] Mix 2 g of P25, 1 g of citric acid and x g of ammonium molybdate (x = 0.4, 0.6, 0.8, 1, 1.2, 1.4) evenly, and then put the mixed powder in an Ar atmosphere at 200°C. Incubate for 1 h, then heat to 850 °C for 2 h to obtain TiO 2 -C-MoO 2 Nanocomposites. The resulting samples were labeled TCM 2:1:0.4, TCM 2:1:0.6, TCM 2:1:0.8, TCM 2:1:1, TCM 2:1:1.2, TCM 2:1:1.4.

[0031] The prepared TiO 2 -C-MoO 2 Nanocomposites for photocatalytic reduction of hexavalent cadmium ions. 10 mg of the nanocomposite was added to a 50 mg / L dichromate solution. After stirring in the dark room for 40 minutes, the solution was irradiated under a 500W xenon lamp light source, 5 ml of the suspension was taken every 2 minutes for centrifugation, and the obtained supernatant was subjected to ultraviolet-visible absorption spectrum testing to obtain photocatalytic reduction VI. Valence Cr data. The experimental results are as Image 6 As shown, TiO 2 -C-MoO 2 The time required for the nanoc...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com