Three-membered ring preparation method without metal catalysis

A three-membered ring and compound technology, which is applied in the field of metal-free catalyzed three-membered ring preparation, can solve problems such as limitations

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

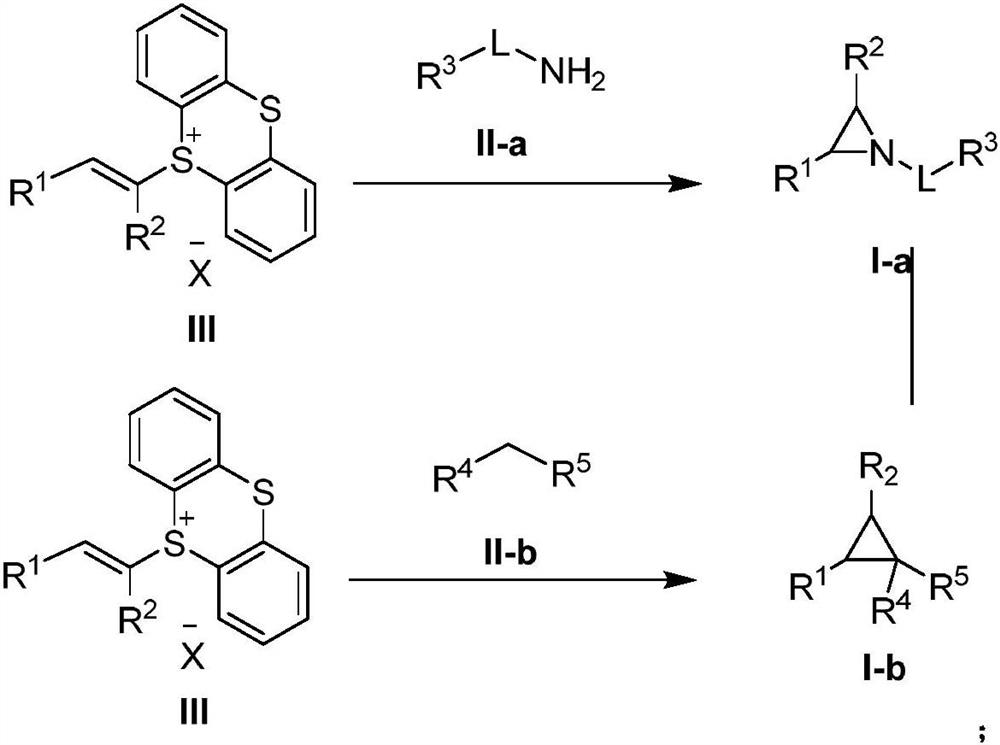

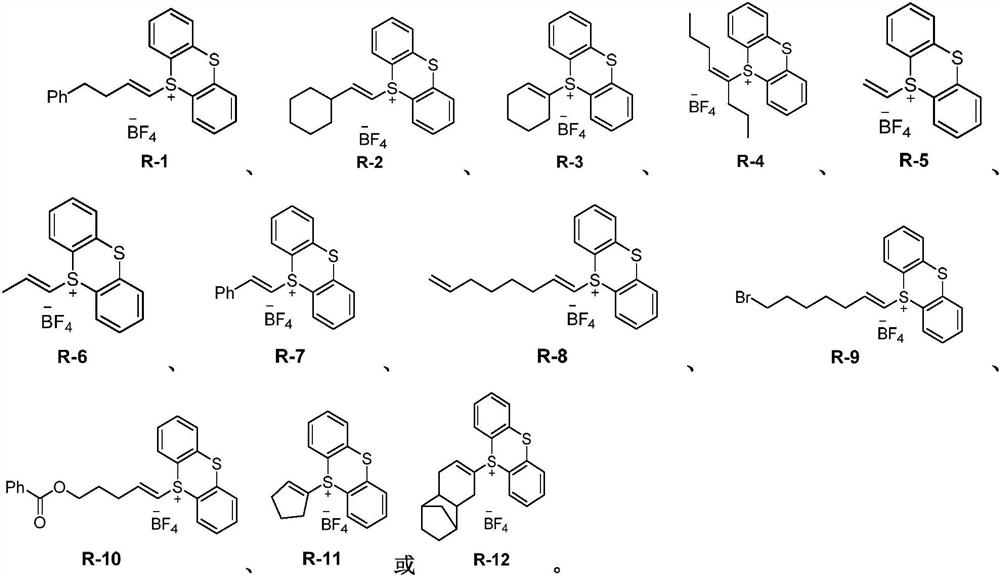

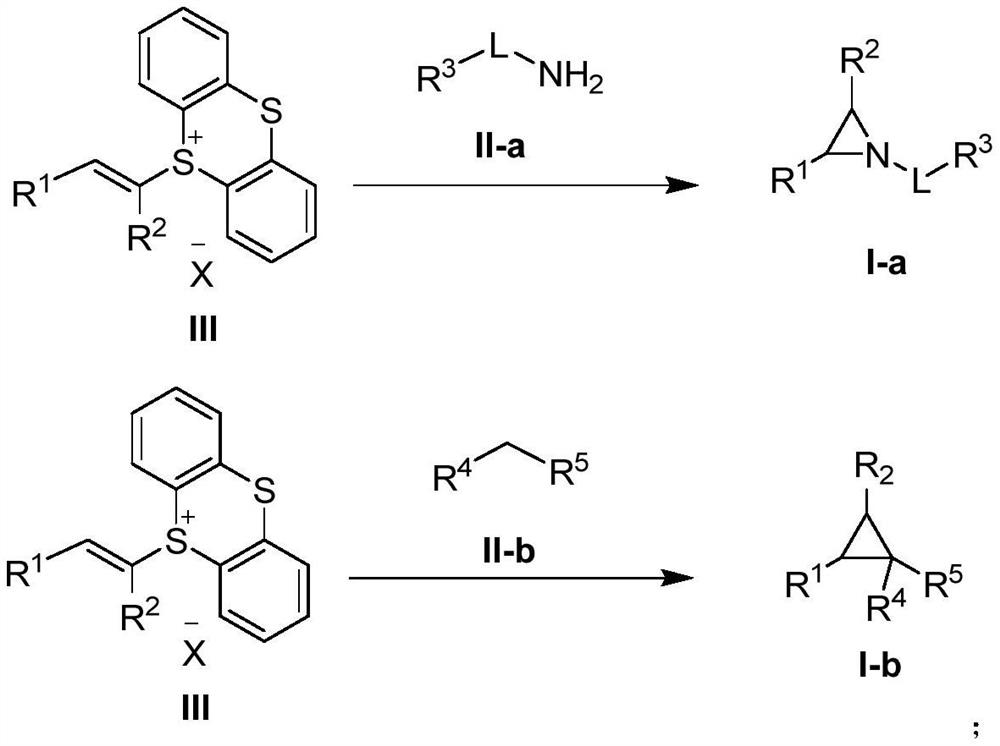

Method used

Image

Examples

Embodiment 1

[0101]

[0102] First p-toluenesulfonamide (41.1mg, 0.24mmol), K 2 CO 3 (27.6 mg, 0.20 mmol) and compound R-1 (86.8 mg, 0.20 mmol) were added to the reaction tube, pumped through a vacuum line for three times, and under a nitrogen atmosphere, DCM (2.0 mL) was added, and the reaction was carried out at room temperature for 24 h. After the reaction was completed, the solvent was removed by rotary evaporation, the sample was loaded by dry method, and purified by column chromatography (petroleum ether:ethyl acetate (v / v)=19:1) to obtain the product P-1 (53.1 mg, yield 88%).

[0103] 1H NMR (400MHz, CDCl 3 )δ7.86–7.81(m,2H),7.34(d,J=8.1Hz,2H),7.32–7.22(m,2H),7.22–7.16(m,1H),7.15–7.09(m,2H) ,2.78(tt,J=7.5,4.7Hz,1H),2.65-2.56(m,3H),2.45(s,3H),2.06(d,J=4.6Hz,1H),1.88(dddd,J=13.9 ,8.8,7.4,4.9Hz,1H),1.67(dtd,J=14.1,8.0,6.4Hz,1H).

[0104] 13 C NMR (101MHz, CDCl 3 )δ144.64,140.80,135.10,129.78,128.57,128.42,128.12,126.23,39.84,34.02,33.25,33.09,21.77;

[0105] HRMS-ESI(m / z)[M+...

Embodiment 2

[0107]

[0108] First p-cyanobenzenesulfonamide (43.7mg, 0.24mmol), K 2 CO 3 (27.6 mg, 0.20 mmol) and compound R-1 (86.8 mg, 0.20 mmol) were added to the reaction tube, pumped through a vacuum line for three times, and under a nitrogen atmosphere, DCM (2.0 mL) was added, and the reaction was carried out at room temperature for 24 h. After the reaction was completed, the solvent was removed by rotary evaporation, dry method was applied, and the product was purified by column chromatography (petroleum ether:ethyl acetate (v / v)=19:1) to obtain the product P-2 (40.5 mg, yield 65%).

[0109] 1 H NMR (400MHz, CDCl 3 )δ8.09–8.03(m,2H),7.87–7.81(m,2H),7.28(td,J=7.7,7.1,1.1Hz,2H),7.23–7.17(m,1H),7.13(dd, J=7.0, 1.8Hz, 2H), 2.91 (tt, J=7.3, 4.9Hz, 1H), 2.72–2.59 (m, 3H), 2.12 (d, J=4.7Hz, 1H), 1.91 (dddd, J =13.9,8.7,7.5,5.1Hz,1H),1.73(dtd,J=14.1,7.9,6.4Hz,1H);

[0110] 13 C NMR (101MHz, CDCl 3 )δ142.59,140.38,132.96,128.68,128.68,128.41,126.42,117.38,117.29,40.52,34.84,33.08,...

Embodiment 3

[0113]

[0114] First p-methoxybenzenesulfonamide (44.9mg, 0.24mmol), K 2 CO 3 (27.6 mg, 0.20 mmol) and compound R-1 (86.8 mg, 0.20 mmol) were added to the reaction tube, pumped through a vacuum line for three times, and under a nitrogen atmosphere, DCM (2.0 mL) was added, and the reaction was carried out at room temperature for 24 h. After the reaction was completed, the solvent was removed by rotary evaporation, the sample was loaded by dry method, and purified by column chromatography (petroleum ether:ethyl acetate (v / v)=19:1) to obtain the product P-3 (43.8 mg, yield 69%).

[0115] 1 H NMR (600MHz, CDCl 3 )δ7.88(d,J=8.6Hz,2H),7.27(t,J=7.5Hz,2H),7.19(t,J=7.4Hz,1H),7.12(d,J=7.5Hz,2H) ,7.00(d,J=8.5Hz,2H),3.88(s,3H),2.75(td,J=7.4,3.7Hz,1H),2.66–2.55(m,3H),2.04(d,J=4.5 Hz,1H),1.88(dddd,J=13.8,8.8,7.3,4.9Hz,1H),1.73–1.63(m,1H);

[0116] 13 C NMR (151MHz, CDCl 3 )δ163.76,140.85,130.32,129.65,128.60,128.46,126.26,114.38,55.80,39.82,33.97,33.27,33.14;

[0117] HRMS-ESI(m...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com