Compound, method for producing same, resin composition, resin sheet, multilayer printed wiring board, and semiconductor device

A technology of resin composition and manufacturing method, applied in the directions of printed circuit, printed circuit, printed circuit manufacturing, etc., can solve the problems of long processing time and the like

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

[0378] Hereinafter, the present embodiment will be described more specifically with reference to Examples and Comparative Examples. This embodiment is not limited to the following examples at all.

[0379] [Synthesis of maleimide compound (TMDM)]

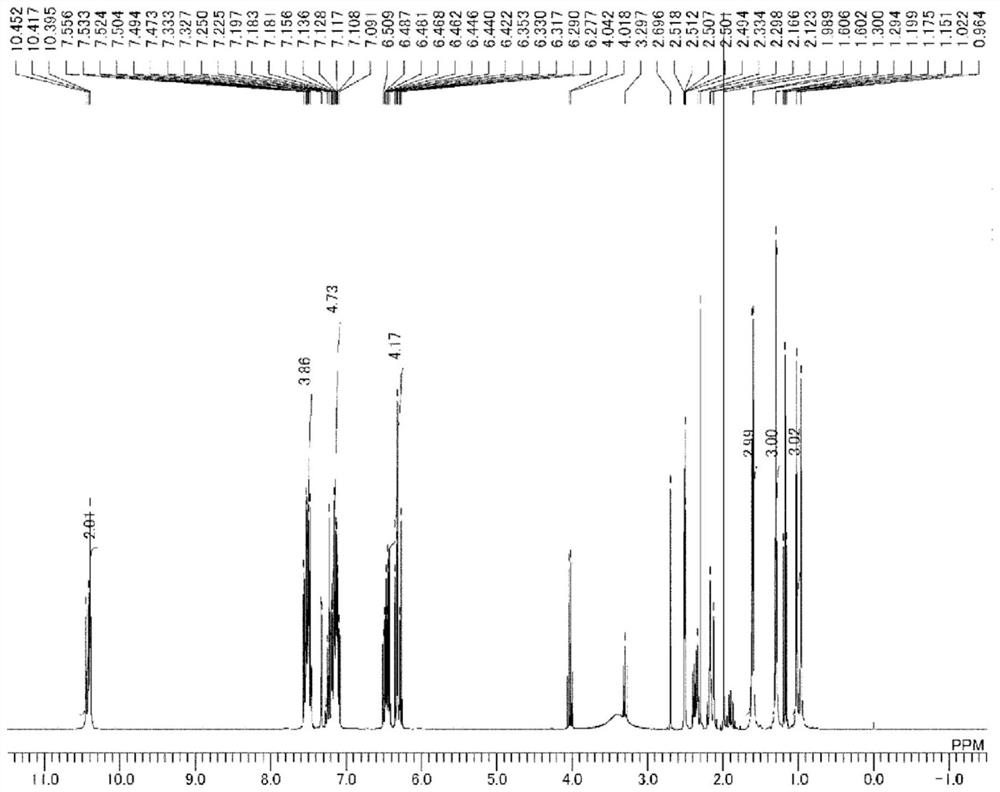

Synthetic example 1

[0381] The compound (TMDM) represented by the formula (20) was synthesized as follows.

[0382] [Synthesis of amic acid compound (hereinafter, abbreviated as MA-TMDA)]

[0383] First, MA-TMDA represented by the formula (32) was synthesized by the following method.

[0384]

[0385] In a 100 mL four-necked flask equipped with an argon blowing inlet, a Dean-Stark trap, a serpentine condenser, and a thermometer, 5.2 g (53 mmol) of maleic anhydride, N-methylpyrrolidone (NMP ) 20 mL and 20 mL of toluene were stirred at room temperature (25° C.) under argon gas flow to completely dissolve maleic anhydride. To this solution, TMDA (manufactured by Junya Pharmaceutical Co., Ltd., 5-amino-1,3,3-trimethyl-1-(4-aminophenyl)-indane and 6-amino-1,3 , 3-trimethyl-1-(4-aminophenyl)-indane mixture) 5.0 g (19 mmol), and NMP 10 mL, and stirred at room temperature (25° C.) for 17 hours.

[0386] A part of the reaction solution was fractionated, water and ethyl acetate were added, and the mi...

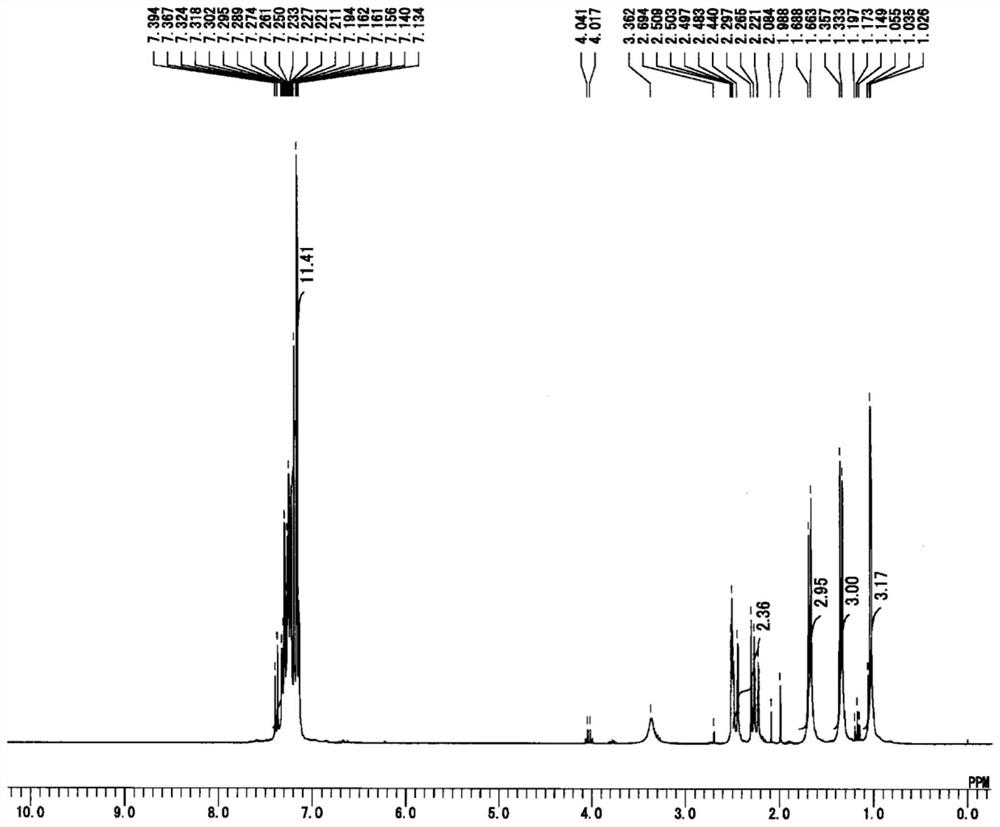

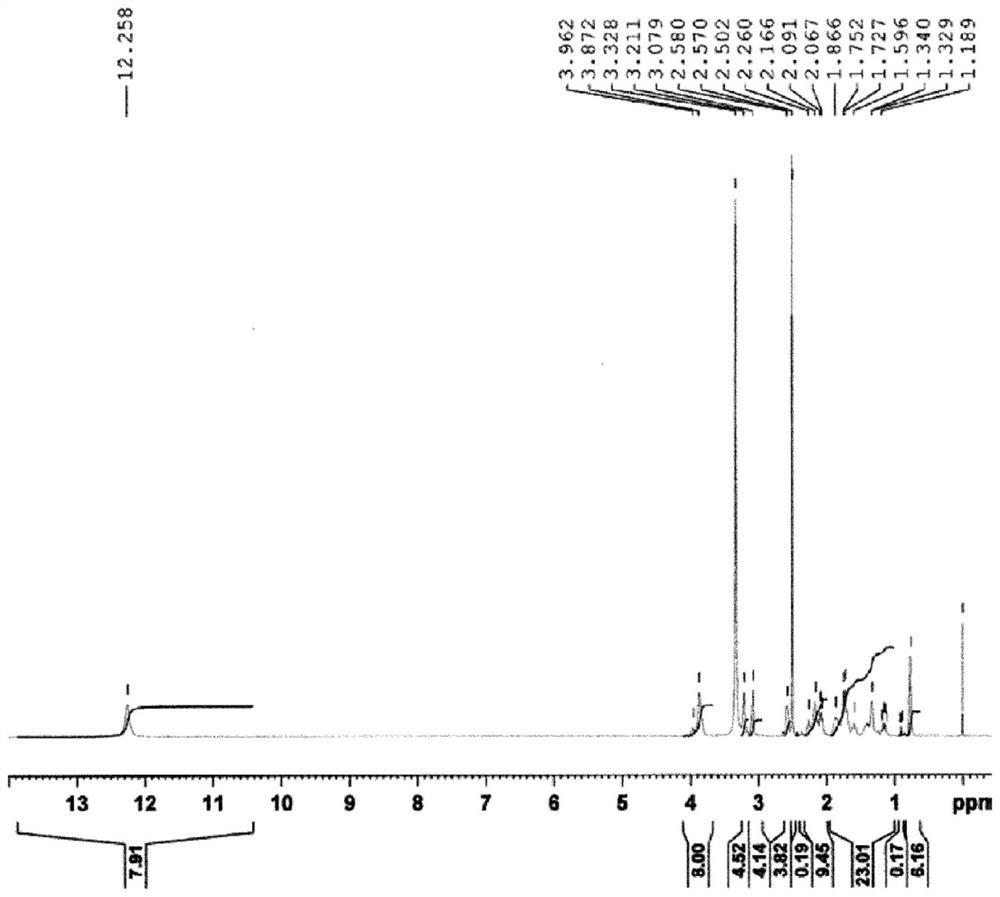

Embodiment 1

[0396] The compound represented by formula (16) (also referred to as compound (A-1)) was synthesized as follows.

[0397] In a 200 mL flask, 6.26 g (25 mmol) of bis(trimethylol)propane (manufactured by Tokyo Chemical Industry Co., Ltd.), cyclohexane-1,2,4-tricarboxylic acid-1,2-anhydride (Mitsubishi Chemical Industries, Ltd.) were added. Gas Chemical Co., Ltd., H-TMAn (trade name) 20.81 g (105 mmol), 4-dimethylaminopyridine 3.05 g (25 mmol), triethylamine 11.13 g and dichloromethane 70 g, at room temperature (25°C) under stirring for 7 hours.

[0398] To the reaction solution, 50 mL of water and 6 mL of methanol were added, and after stirring for 1 hour, 50 mL of 5% hydrochloric acid was further added and stirred. Then, the liquid was separated, the aqueous layer was removed, and 350 mL of methyl ethyl ketone and 100 mL of 5% hydrochloric acid were added to the organic layer. The solution was transferred to a separatory funnel, washed once with 150 mL of 5% hydrochloric acid...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| wavelength | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com