High-selectivity nanofiltration membrane as well as preparation method and application thereof

A high-selectivity, nanofiltration membrane technology, applied in the field of membrane separation, can solve problems such as clogging, reduced lithium ion extraction efficiency, and reduced separation efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

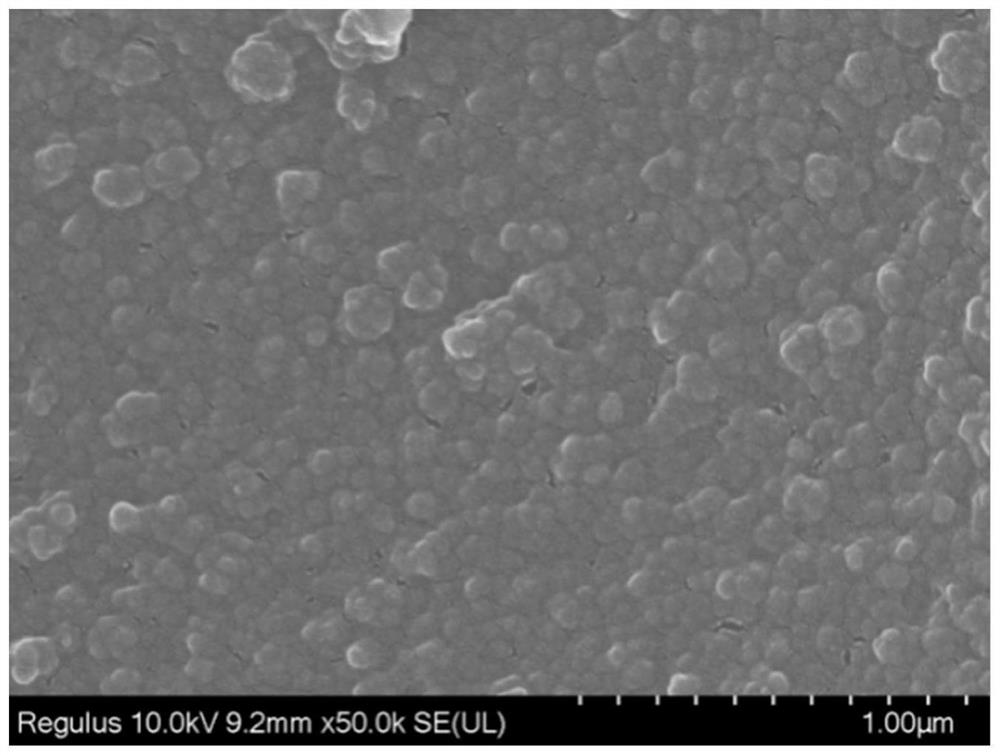

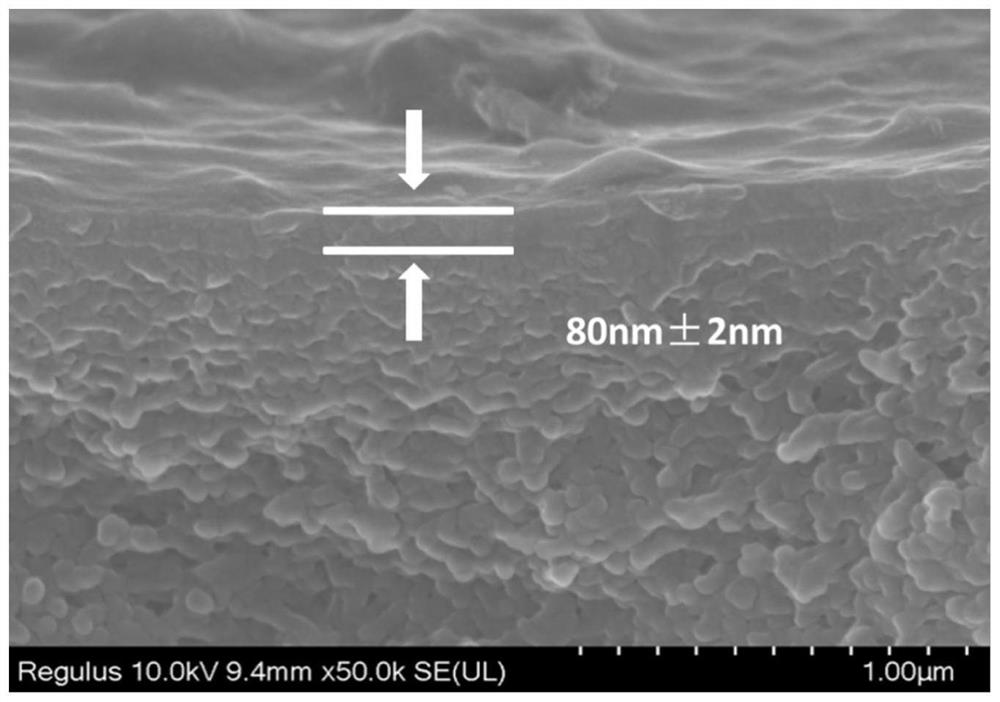

Image

Examples

Embodiment 1

[0049] First, configure the following solution:

[0050] 3.0wt% of piperazine, 1.0wt% of triethylamine aqueous phase mixed solution (1); 1.0wt% of 1,3,5-benzenetricarbonyl chloride n-hexane organic phase solution (2); and 3.0wt% of paraben Aminosalicylic acid-ethanol solution (3).

[0051] Then, the polyethersulfone / sulfonated polysulfone-based membrane is contacted with the aqueous phase solution (1) for 2 minutes, and after being taken out, the excess aqueous phase solution on the surface is removed with a roller or an air knife; then the membrane and the organic phase solution are removed. (2) contact for 5 minutes, complete the interfacial polymerization reaction, form a polyamide layer, and then remove the excess organic phase solution on the surface; then contact the film with the p-aminosalicylic acid-ethanol solution (3) for 10 minutes to complete the connection. branch reaction; then remove the superfluous solution on the surface, soak the membrane in the 2000ppm sol...

Embodiment 2

[0053] First, configure the following solution:

[0054] Mixed aqueous phase solution of 0.5wt% piperazine and 0.5wt% triethylamine (1); 0.1wt% 3,3',5,5'-biphenyltetracarbonyl chloride n-hexane organic phase solution (2) ; 0.1 wt% p-aminobenzoic acid-ethanol solution (3).

[0055] Then, the polyethersulfone porous membrane is used as the base membrane to contact the aqueous phase solution (1) for 2 minutes, and after taking out, the excess aqueous phase solution on the surface is removed with a roller or an air knife; then the membrane and the organic phase solution (2) are removed. ) contact for 1 minute, complete the interfacial polymerization reaction, form polyamide layer, then remove the superfluous organic phase solution on the surface; Then the film is contacted with the 4-aminophthalic acid-water solution (3) for 1 minute to complete the grafting reaction; Then, the excess solution on the surface was removed, and the membrane was immersed in a 1000 ppm solution prepar...

Embodiment 3

[0057] First, configure the following solution:

[0058] 2.0wt% piperazine, 0.5wt% triethylamine mixed aqueous phase solution (1); 0.5wt% 1,3,5-benzenetricarbonyl chloride n-hexane organic phase solution (2); 0.5wt% paraffin Aminosalicylic acid-ethanol solution (3).

[0059] Then, the polysulfone ultrafiltration base membrane is contacted with the aqueous phase solution (1) for 2 minutes, and after being taken out, the excess aqueous phase solution on the surface is removed with a roller or an air knife; then the membrane is contacted with the organic phase solution (2) In 30 seconds, the interfacial polymerization reaction was completed to form a polyamide layer, and then the excess organic phase solution on the surface was removed; then the film was contacted and reacted with the p-aminosalicylic acid-ethanol solution (3) for 3 minutes to complete the grafting reaction; then Remove the excess solution on the surface, and then soak the membrane in the 5000ppm solution prepar...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com