Preparation method for synthesizing nano rare earth boride material at low temperature by microwave heating

A nano-rare earth, microwave heating technology, applied in boron compounds, chemical instruments and methods, chemical/physical/physical-chemical processes of applying energy, etc. The effect of increasing productivity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

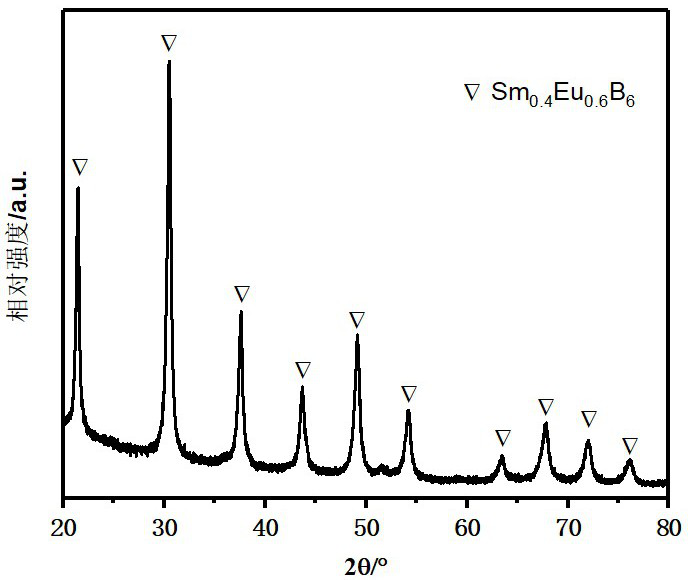

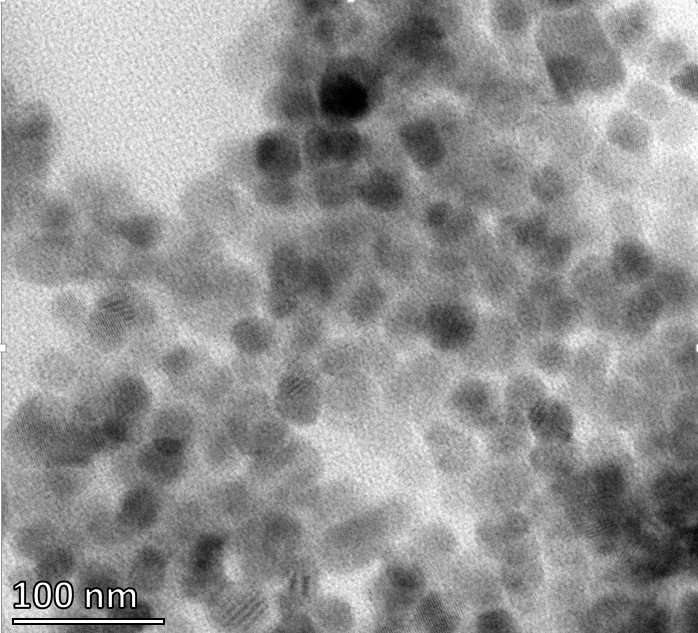

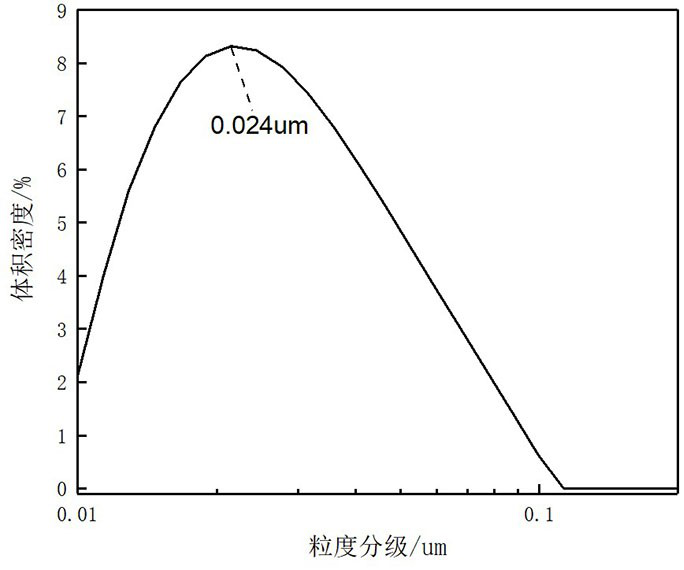

[0042] Nano rare earth boride Sm 0.4 Eu 0.6 B 6 The preparation method specifically comprises the following steps:

[0043] It is to weigh 29.1g of europium chloride hexahydrate, 43.5g of samarium chloride hexahydrate, 27.4g of magnesium diboride and 200g of water and put it into a ball milling jar for ball milling, rotating speed 150r / min, ball milling for 24h, and pour the slurry after completion. Put it into a tray and then put it into an 80°C oven for drying. After drying, it is put into a pulverizer and pulverized to obtain a precursor powder. Put the precursor powder into a quartz crucible, then put it into a vacuum microwave oven, and evacuate it to -0.1MPa. Then turn on the vacuum microwave oven 2350MHz for microwave heating, the temperature is 150°C, and the reaction time is 3min. After the reaction is completed, the crude powder is obtained, and then acid-washed twice with 3 mol / L dilute hydrochloric acid, and then washed twice with water until the pH value reac...

Embodiment 2

[0046] Nano rare earth boride LaB 6 The preparation method specifically comprises the following steps:

[0047] It is to weigh 19.5kg of lanthanum bromide heptahydrate, 6.76kg of magnesium diboride and 10kg of water and put it into a ball mill tank for ball milling, the rotation speed is 300r / min, and the ball milling is 24h. Dry. After drying, it is put into a pulverizer and pulverized to obtain a precursor powder. Put the precursor powder into a quartz crucible, then put it into a vacuum microwave oven, and evacuate it to -0.1MPa. Then turn on the vacuum microwave oven 8000MHz for microwave heating, the temperature is 160°C, and the reaction time is 60min. After the reaction is completed, a crude powder is obtained, which is then acid washed twice with 3 mol / L dilute hydrochloric acid, and then washed twice with water until the pH value reaches 7, and then freeze-dried at -8 °C to obtain pure nanometers. LaB 6 Powder 6kg.

[0048] for the obtained nano-LaB 6 The powde...

Embodiment 3

[0050] Nano rare earth boride Gd 0.2 Ce 0.8 B 6 The preparation method specifically comprises the following steps:

[0051] It is to weigh 2.42kg of gadolinium bromide hexahydrate, 2.55kg of cerium chloride hexahydrate, 3.3kg of magnesium diboride and 3kg of water and put it into a ball mill tank for ball milling, rotating speed 300r / min, ball milling for 24h, and pouring the slurry after completion. Put it into a tray and then put it into a 120°C oven for drying. After drying, it is put into a pulverizer and pulverized to obtain a precursor powder. The precursor powder was placed in a ceramic container, then placed in a vacuum microwave oven, and evacuated to -0.1MPa. Then turn on the vacuum microwave oven 6000MHz for microwave heating, the temperature is 160°C, and the reaction time is 30min. After the reaction is completed, a crude powder is obtained, which is then acid washed twice with 3 mol / L dilute hydrochloric acid, and then washed twice with water until the pH va...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com