Sealant for food and beverage cans and preparation method thereof

A technology for beverage cans and sealants, applied in adhesives, sustainable manufacturing/processing, bio-packaging, etc., can solve problems such as poor retort resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

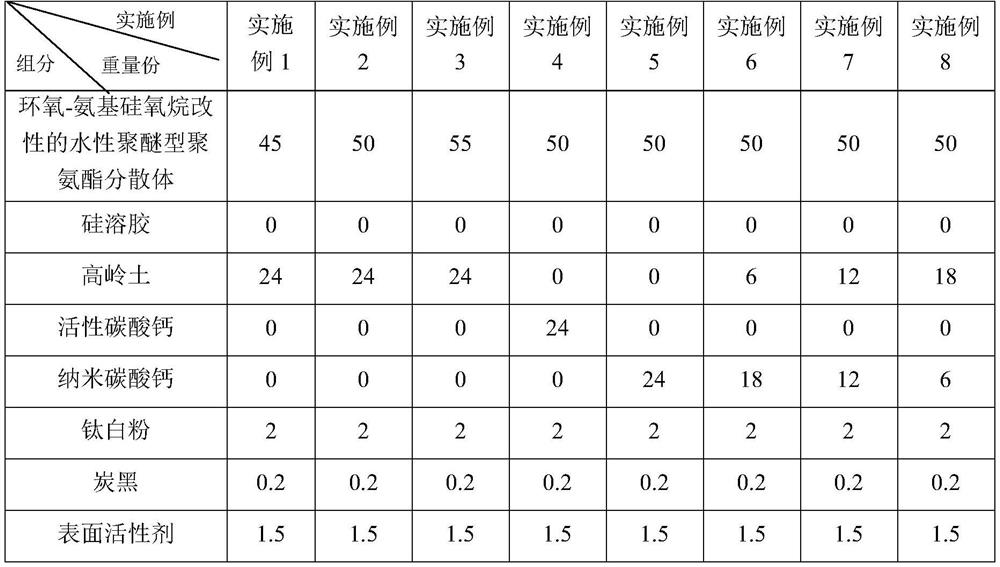

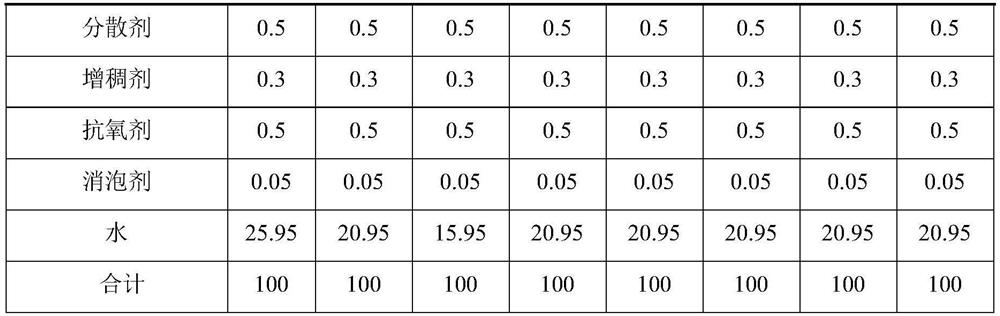

[0026] Each component and its parts by weight in the embodiment 1-8 of table 2

[0027]

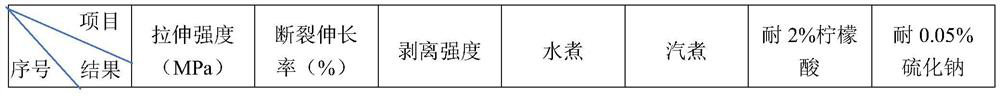

[0028]

[0029] Wherein, the preparation of epoxy-aminosiloxane-modified water-based polyether polyurethane dispersion is as follows:

[0030] Under nitrogen protection, 50 g of polyether polyol (polypropylene glycol, PPG-2000), 5 g of hexamethylene diisocyanate (HDI) and 0.1 g of dibutyltin dilaurate (DBTDL) after vacuum dehydration were added to the In the three-necked flask with reflux condenser, stirrer and thermometer, the temperature was raised to about 90°C for reaction for 2h; 6g epoxy resin E-44 was added, 10g acetone was added to adjust the viscosity of the system, after 1h of reaction, the temperature of the system was lowered to 60°C, 5g was added 3-Aminopropyltriethoxysilane (KH550), react for 1h; then sample and measure the isocyanate content in the reactant; after reaching 0.78%, add 2g of dimethylolpropionic acid (DMPA) to react for 1h; add 1.5g Triethylamine (TEA) ...

Embodiment 9

[0037] Example 9: a sealant for food and beverage cans, the difference from Example 8 is that the weight part of silica sol is set to 1 part, and the weight part of water is set to 19.95 parts.

Embodiment 10

[0038] Example 10: A sealant for food and beverage cans, the difference from Example 8 is that the parts by weight of silica sol are set to 3 parts, and the parts by weight of water are set to 17.95 parts.

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com