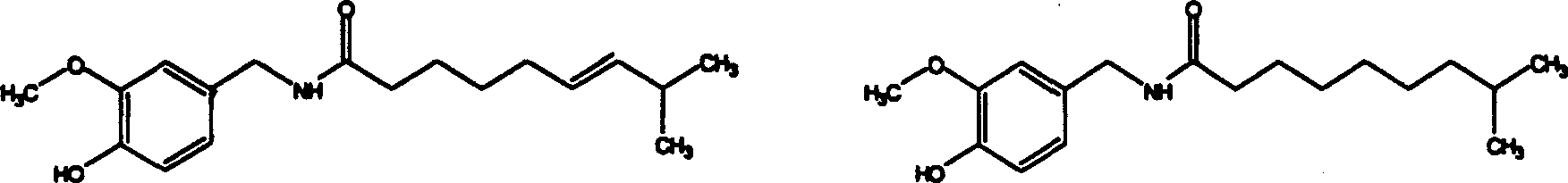

Molecular distilling process for enriching and purifying capsaicin

A technology of molecular distillation and capsaicin, which is applied in the separation/purification of carboxylic acid amide, organic chemistry, etc., can solve the problems of waste liquid and gas pollution, high requirements for industrial equipment, and high cost of equipment, so as to achieve simple process operation and ensure natural The effect of quality and less pigment residue

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0030] Weigh 600g of dried red pepper peel powder produced in Badong, Hubei, extract with 3000ml of acetone at 40°C for 3 times under constant stirring, each time for 1h, filter, combine the filtrates, concentrate and recover acetone. Mix the concentrate and olive oil evenly at a ratio of 1:4 (V / V), under a vacuum of 15Pa, a distillation temperature of 95°C, a material flow rate of 3ml / min, a condensation surface temperature of 25°C, a wiper speed of 350rpm, and a temperature of circulating water At 75°C, molecular distillation removes residual acetone. The acetone-removed material was molecularly distilled at a vacuum of 0.5 Pa, a distillation temperature of 150°C, a material flow rate of 2ml / min, a condensation surface temperature of 25°C, a wiper speed of 300rpm, and a circulating water temperature of 75°C. The distillate was dissolved with 60 mL of petroleum ether, extracted three times with 180 mL of 50% (V / V) aqueous ethanol, the aqueous ethanol layers were combined, and...

Embodiment 2

[0032]Weigh 600g of dry peel powder of red pepper produced in Chongqing, Sichuan, extract with 3600mL 95% (V / V) ethanol at 60°C under constant stirring twice, each time for 1h, filter, combine the filtrates, concentrate and recover ethanol. Mix the concentrate and olive oil evenly at a ratio of 1:7 (V / V), at a vacuum of 20Pa, a distillation temperature of 100°C, a material flow rate of 3ml / min, a condensation surface temperature of 25°C, a wiper speed of 250rpm, and a temperature of circulating water Molecular distillation at 70°C removes ethanol and water. The material after desolvation is molecularly distilled under the conditions of vacuum degree of 1Pa, distillation temperature of 160°C, material flow rate of 1ml / min, condensation surface temperature of 25°C, wiper speed of 250rpm, and circulating water temperature of 70°C. After the distillate was dissolved with 60mL of petroleum ether, it was extracted 4 times with 60mL of 50% (V / V) aqueous ethanol, and the aqueous ethan...

Embodiment 3

[0034] Weigh 600g of dried red pepper peel powder produced in Badong, Hubei, extract with 3000mL of 50% (V / V) ethanol aqueous solution at 60°C under constant stirring for 3 times, each time for 1h, filter, combine the filtrates, concentrate and recover ethanol. Mix the concentrate and olive oil evenly at a ratio of 1:1 (V / V), under a vacuum of 10Pa, a distillation temperature of 90°C, a material flow rate of 3ml / min, a condensation surface temperature of 25°C, a wiper speed of 450rpm, and a temperature of circulating water At 75°C, molecular distillation removes ethanol and water. The material after desolvation is molecularly distilled under the conditions of vacuum degree of 0.1Pa, distillation temperature of 140°C, material flow rate of 3ml / min, condensation surface temperature of 25°C, wiper speed of 450rpm, and circulating water temperature of 75°C. The distillate was dissolved with 60 mL of petroleum ether, extracted twice with 300 mL of 50% (V / V) aqueous ethanol, combine...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com