Method for preparing 4-aninodiphenylamine

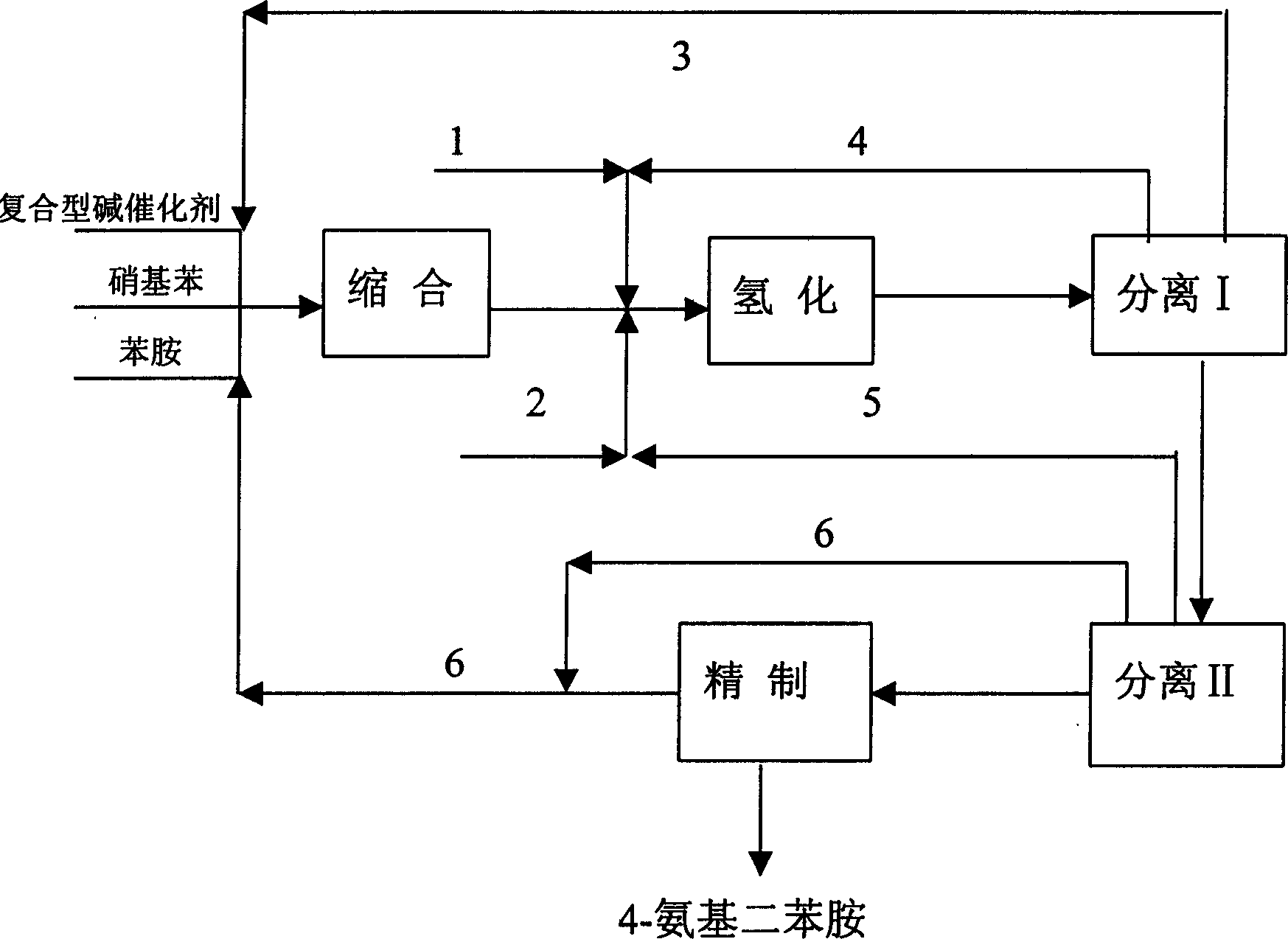

A technology of aminodiphenylamine and aniline, which is applied in the field of preparation of 4-aminodiphenylamine, can solve the problems of expensive catalyst, low product purity, production scale limitation, etc., achieve high conversion rate and selectivity, continuous preparation process, reduce pollution effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0038] At the same time, turn on the composite catalyst, aniline and nitrobenzene delivery pumps, adjust the flow rate to 150 kg / hour for aniline, 30 kg / hour for nitrobenzene, and 100 kg / hour for the composite alkali catalyst, and continuously enter the forced heat exchanger for forced heat exchange. The heat medium of the heat exchanger is alcohol vapor, and the condensed liquid in the heat exchanger is forced to enter the first-stage reactor from the top to continue dehydration and reaction, and then open the bottom valve of the first-stage reactor and the condensation circulation pump to adjust the outlet of the condensation circulation pump The valve makes the material return to the forced heat exchanger to form a partial circulation system, so that the material is continuously circulated, dehydrated and reacted. Control the reaction temperature to 75°C, the pressure (absolute pressure) to 0.008MPa, and control the circulating fluid flow rate to 2 meters 3 / Hour. As the r...

Embodiment 2

[0045] In a 500 ml three-necked flask equipped with a condenser and a stirrer, add 230 grams of water, add 91 grams of tetramethylammonium hydroxide (50%, 0.50 moles, the rest are water), 20 grams of sodium hydroxide in different order (0.5 mole), 52 grams (0.25 mole) of tetramethyl ammonium carbonate, control mixing temperature 72-77 (℃), stir evenly, promptly make composite type alkali catalyst, concentration 29.9 (weight %).

Embodiment 3

[0047] Get 46 grams of nickel powder, 51 grams of aluminum powder, and 3 grams of copper powder, melt in an induction furnace, discharge, cool, and roll into powder, process, sieve, and keep the mesh number at 40-300 mesh. In the there-necked flask of 500 milliliters, thermometer and stirrer are housed, and 375 gram concentration of charging is the NaOH aqueous solution of 20%, slowly adds the obtained powder, and reaction temperature is kept on 60 ℃, and the reaction time is 4 hours, and the back water washes catalyst to Neutral, that is, a composite powder catalyst.

PUM

| Property | Measurement | Unit |

|---|---|---|

| melting point | aaaaa | aaaaa |

| freezing point | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com