Planar electron emitter (PEE), display using it and method for transmitting electron

A technology for electron emission and flat panel display, which is applied in the direction of electrical components, semiconductor devices, and main electrodes of discharge tubes, etc., and can solve problems such as large energy loss, shortened electron mean free path, and large power consumption

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

example 1

[0228] Example 1. Field Emission Flat Panel Display (FE-FPD)

[0229] An obvious application of the invention is structural components for robust, reliable, large, low power loss and inexpensive field emission flat panel displays (FE-FPD).

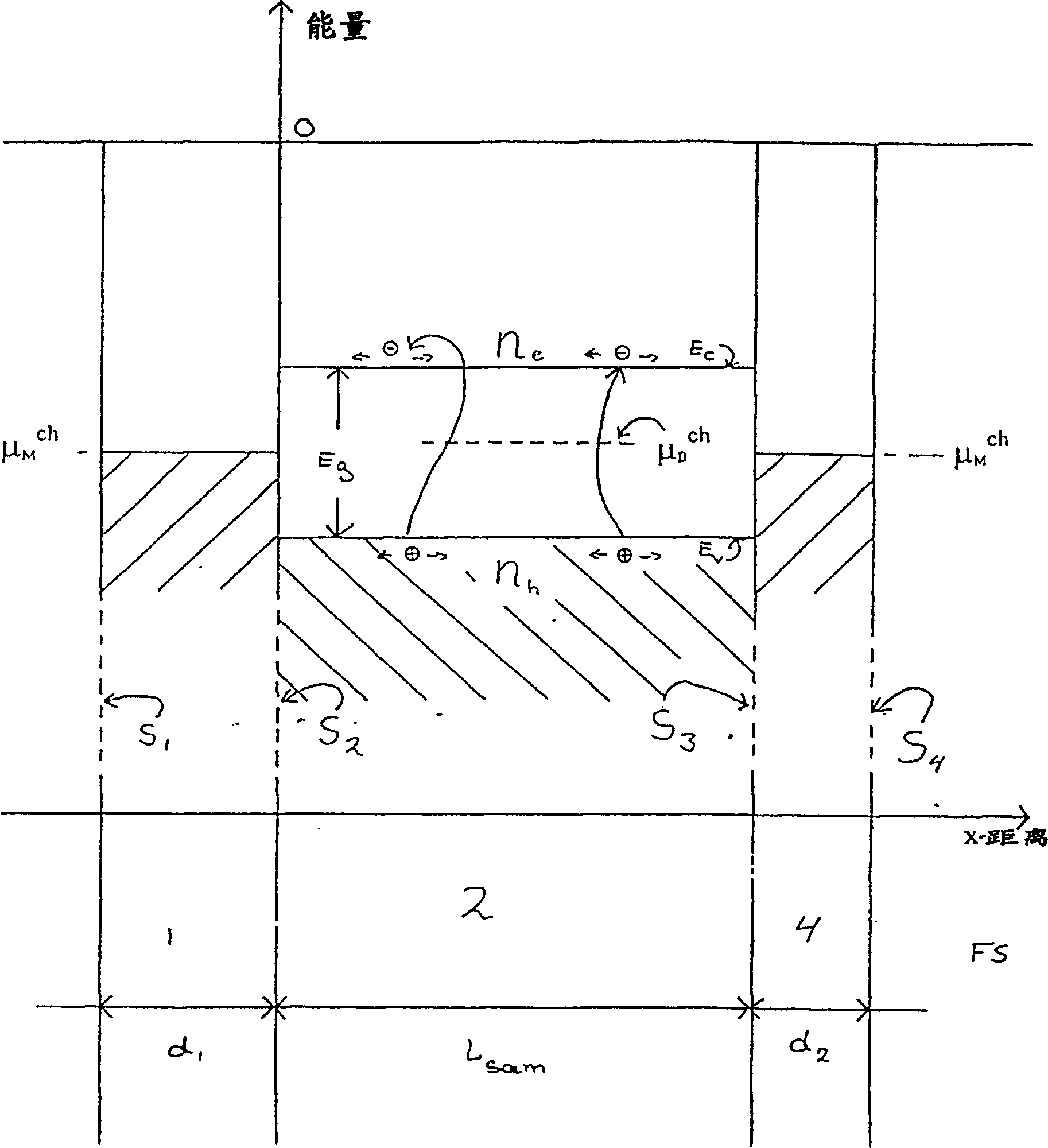

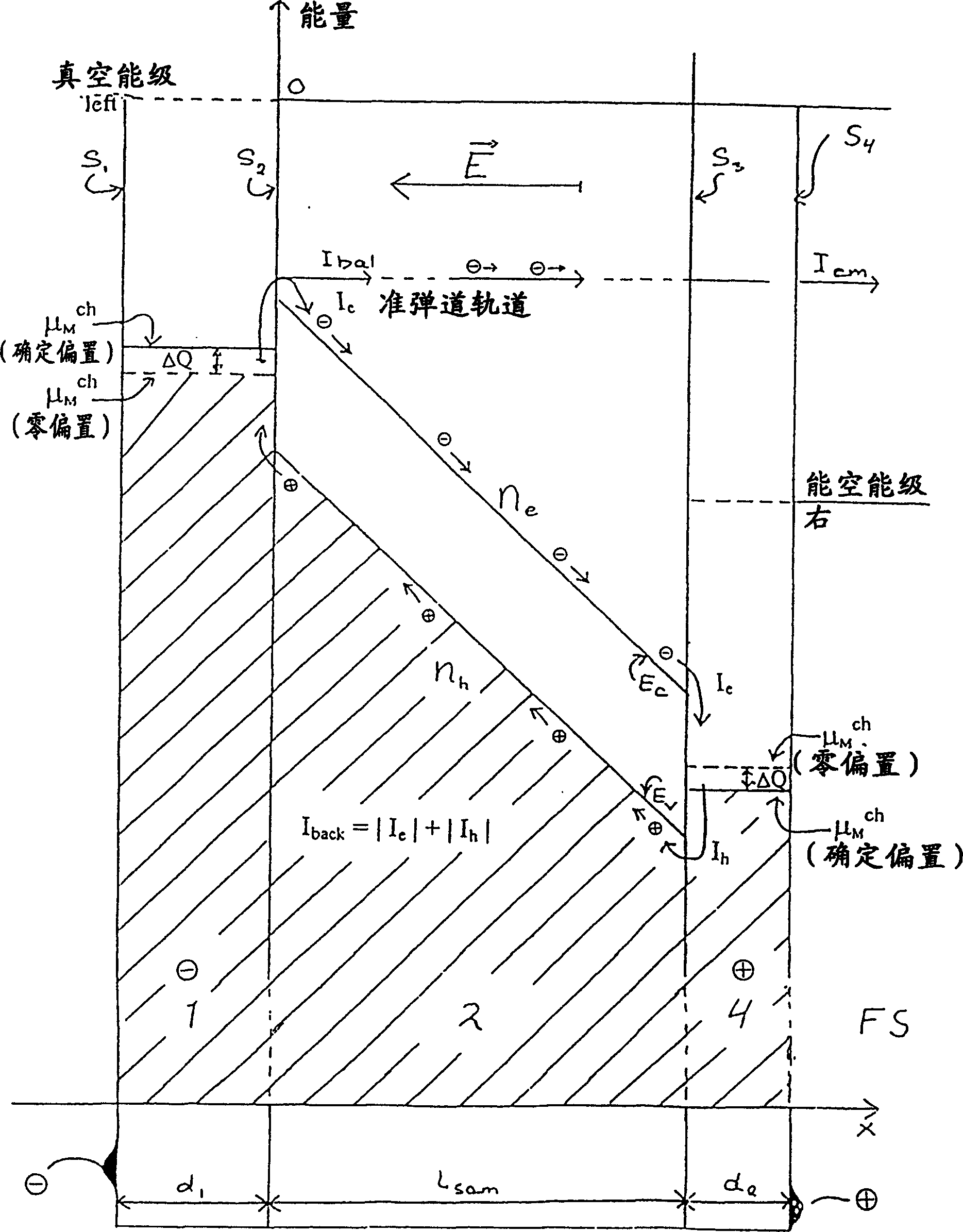

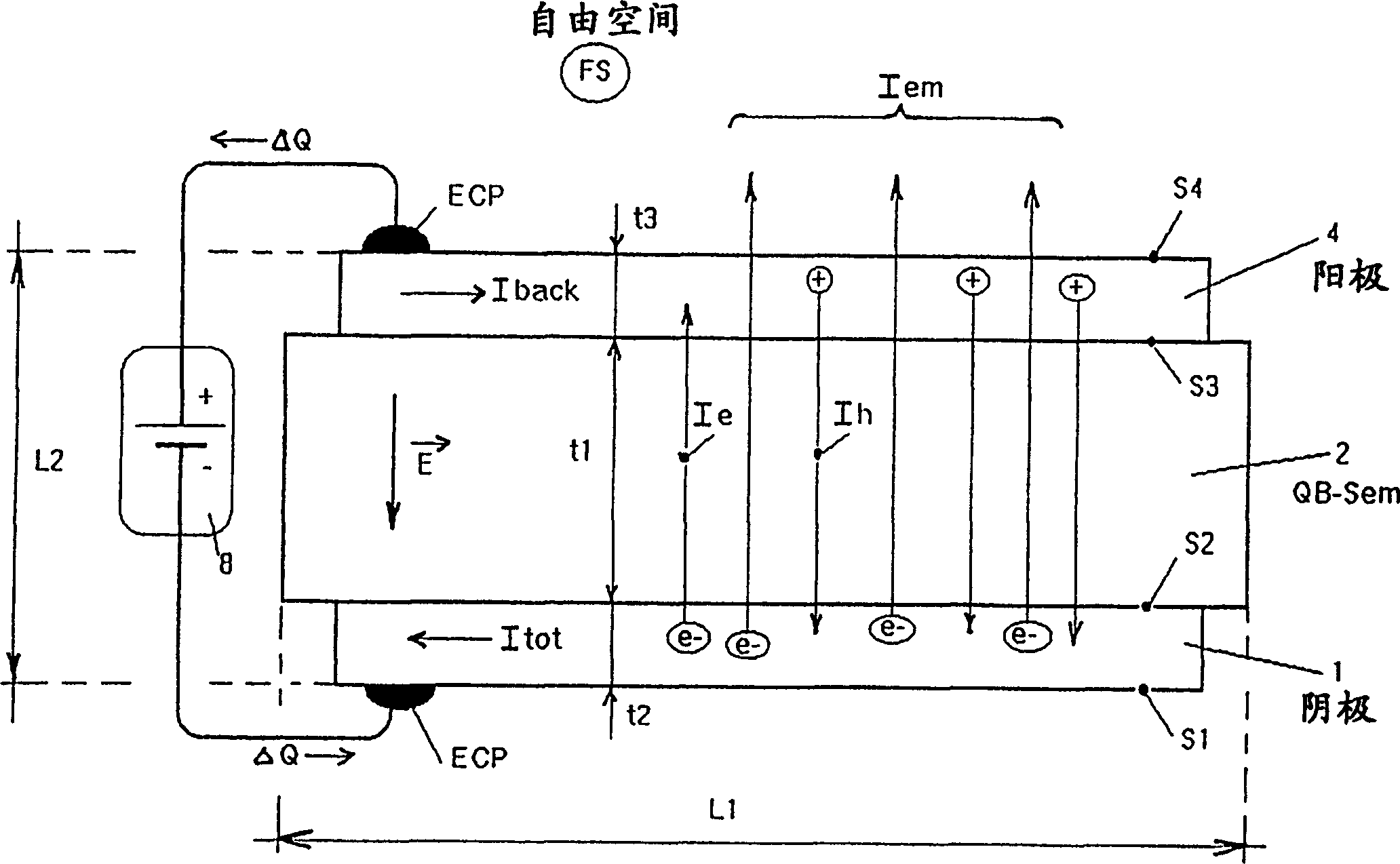

[0230] Figure 4 , that is along Figure 5 The cross-sectional view of the FE-FPD shown in , is one of the possible vacuumless FE-FPDs according to the present invention. see image 3 , the basic planar structure of the present invention-1 (cathode), 2 (QB-Sem) and 4 (anode-be light transparent in this preferred embodiment) in Figure 4 is also clearly shown. The only difference is that in this flat panel display application of the invention the cathode and anode are patterned and an additional thin layer 3 is introduced between the surface S3 of the QB semiconductor and the anode 4 . This third thin layer includes optional (patterned) red 5, yellow 18 and blue 11 segments formed from phosphors or other colored light emitters. The se...

example 2

[0238] Example 2. Planar Electron Beam Lithography

[0239] The main disadvantages caused by the short lifetime of prior art planar electron emitters are solved by using the planar electron emitter according to the invention. The invention provides a qualitatively novel and robust solution to the modern needs of the semiconductor industry. This method and example are shown in Figures 9 to 14 middle.

[0240] In the prior art, the used Figure 8 A schematic diagram of the principle of planar electron beam lithography is depicted. In the prior art section, a projection system for electron lithography has been described using a prior art planar electron emitter. The planar electron emitters of the present invention can be directly implemented in place of prior art emitters.

[0241] A possible embodiment of such a planar electron emitter structure according to the invention is shown in Figure 10 middle. It is the same as existing technology Figure 8 The main difference...

example 3

[0246] Example 3. Two-dimensional lighting board

[0247] Due to the simple structure, robustness, low power consumption, low operating temperature and two-dimensional nature of the planar electron emitter according to the present invention, the planar electron emitter can be conveniently used as a two-dimensional (planar and non-planar) illumination source .

[0248] One such possible lighting panel is schematically shown at Figure 15 and 16 middle. Here the basic structure of the planar electron emitter (the cathode 1, the QB semiconductor 2 and the anode 4 are used as a planar electron source (when a suitable voltage is applied between the cathode and the anode) to inject electrons into the free space FS). These electrons are accelerated by the accelerating electrode 7 in free space and enter the light emitting layer 3 . An optically transparent plate 13 , usually a glass plate, which enables the escape of the generated light energy from the structure (together with pl...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com