Residual polymer eliminating method

A technology of reactive gases and polymers, which is applied in the manufacture of electrical components, semiconductor/solid-state devices, circuits, etc., can solve problems such as inability to remove, and achieve the effects of deleting removal steps and time, shortening the stability of product output, and stabilizing product output

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

no. 1 example

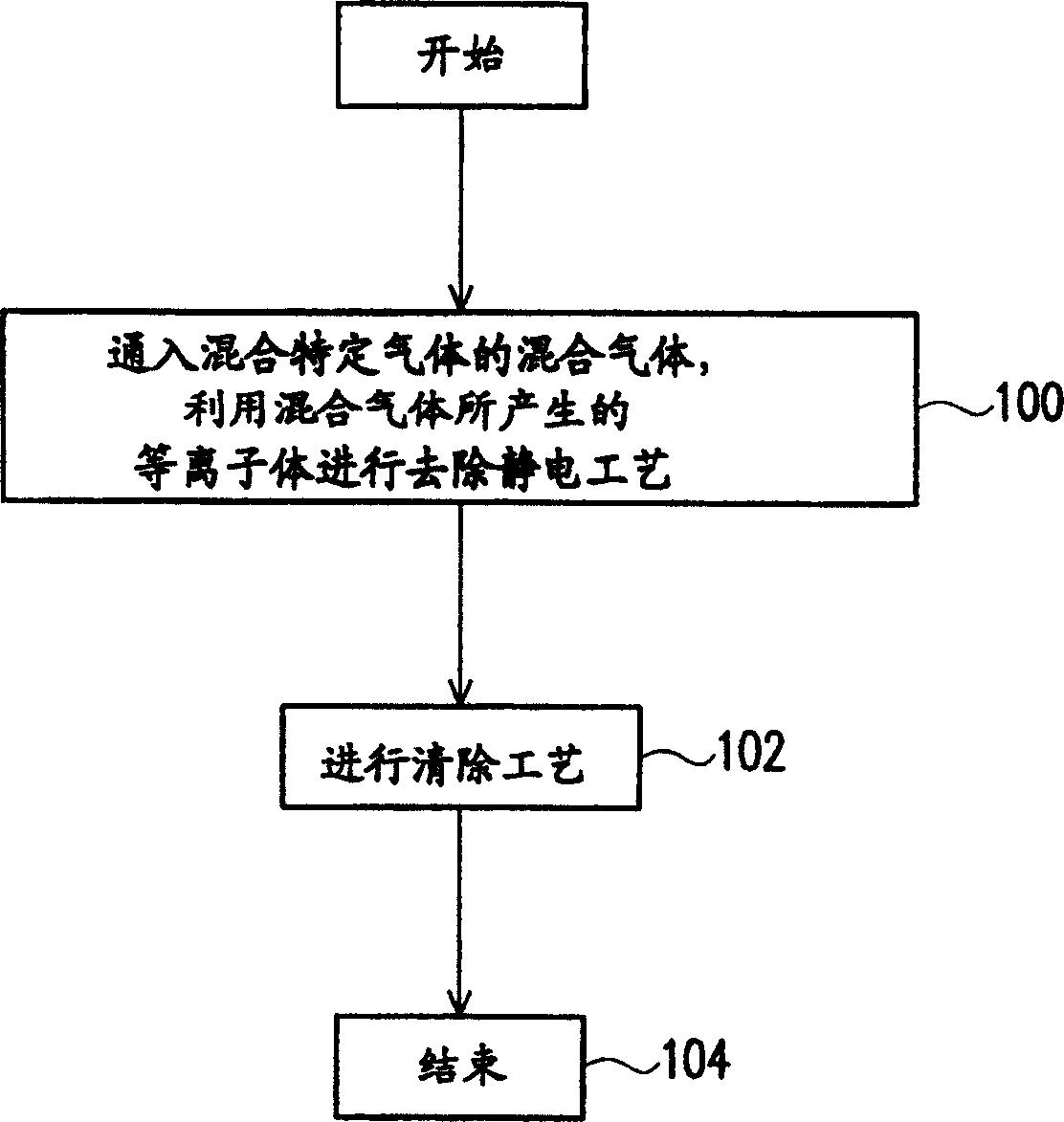

[0033] figure 1 It is a flow chart of steps for removing residual polymer according to a preferred embodiment of the present invention, which can be applied to an etching process for forming openings in a dielectric layer, wherein the dielectric layer is, for example, a silicon oxide dielectric layer, and the dielectric layer is The openings formed in, for example, Metal Via (MVIA) openings, Contact (Contact) openings, and Dual Damascene (Dual Damascene) openings. Moreover, this embodiment adopts a machine of a magnetic field enhanced reactive ion etching (Magnetic-Enhanced RIE, MERIE for short) system.

[0034] The reaction gas usually used for etching is a gas containing carbon fluoride, such as tetracarbon octafluoride (C 4 F 8 ), five carbon octafluoride (C 5 F 8 ) or tetracarbon hexafluoride (C 4 F 6). Because after the etching process is carried out on the machine of the magnetic field enhanced reactive ion etching system, it is easy to have the problem of uneven ...

no. 2 example

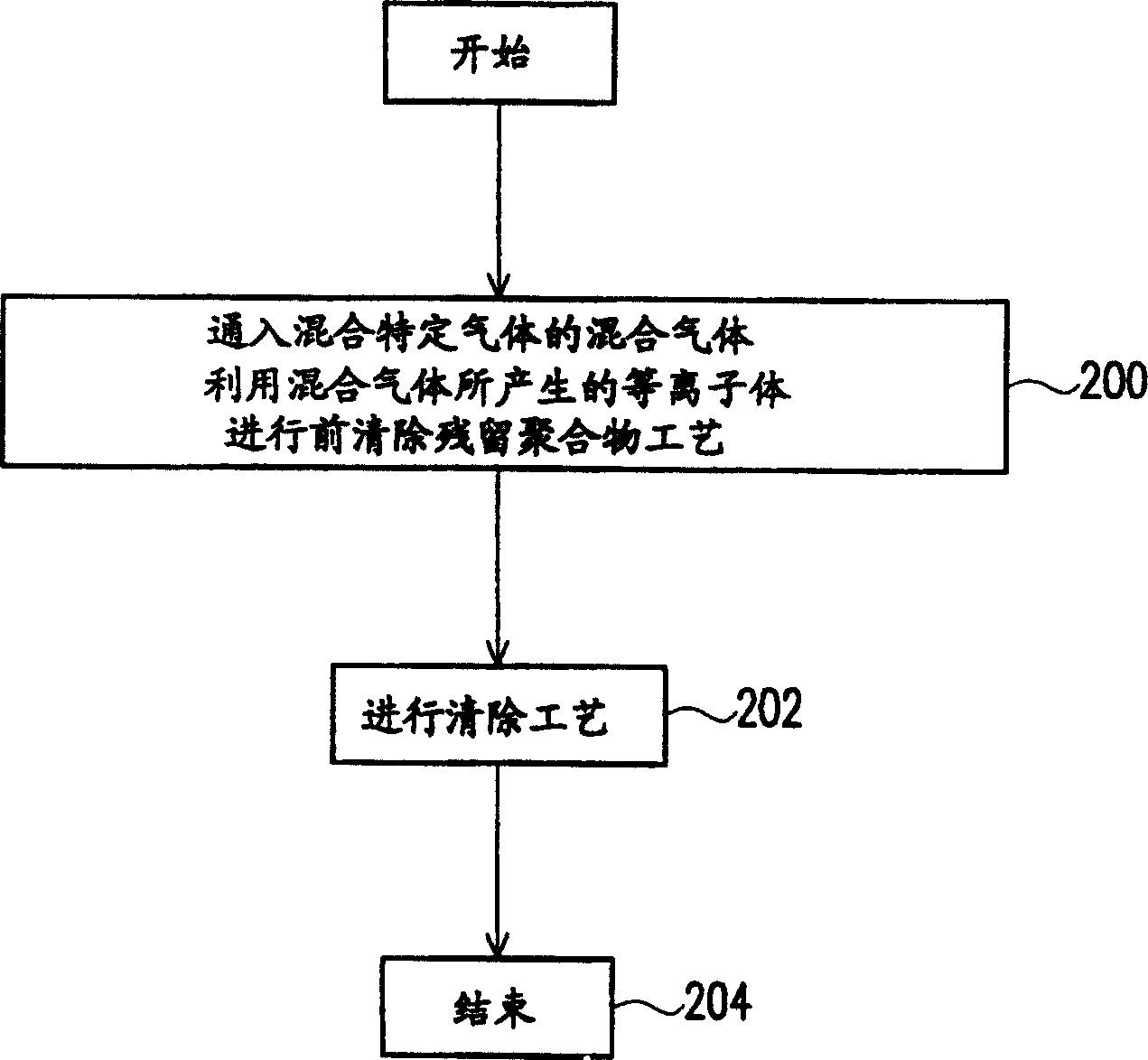

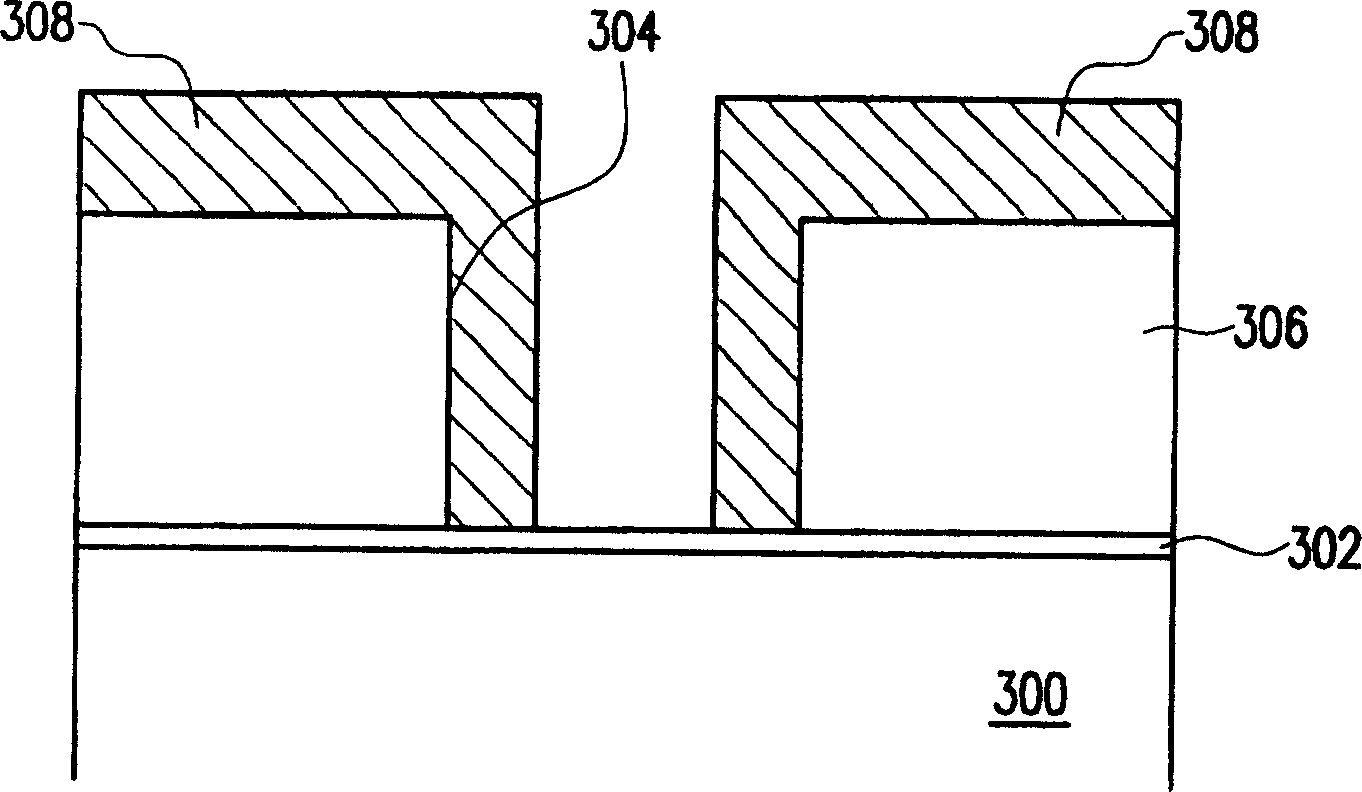

[0040] figure 2 It is a flowchart of steps for removing residual polymer according to another preferred embodiment of the present invention, which can be applied to the removal process of barrier layer (Stcp Layer), wherein the barrier layer is, for example, self-aligned contact window (Self Align CONT), no The borderless CONT, the barrier layer for etching the dielectric layer in the dual damascene process, etc., are made of silicon nitride, silicon carbide or silicon oxynitride, for example. In order to illustrate the position of the above-mentioned barrier layer, take the example of etching and removing the barrier layer in the step of forming the via window opening in the dual damascene process, please refer to Figure 3A and Figure 3B A schematic diagram of the manufacturing process for forming via openings and trenches in the dual damascene process is shown.

[0041] Please refer to Figure 3A , a barrier layer 302 has been formed on the substrate 300 , and a dielec...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com