Method of preparing (001) high orientation diamond film using H cation etching diamond nuclear

A technology of diamond film and ion etching, which is applied in metal material coating process, gaseous chemical plating, coating, etc., can solve the problem of high grain boundary density and impurity concentration, low nuclear density, and reduced adhesion between film and substrate problems such as low grain boundary density and impurity concentration, smooth surface, and the effect of promoting the reduction of grain boundary density

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

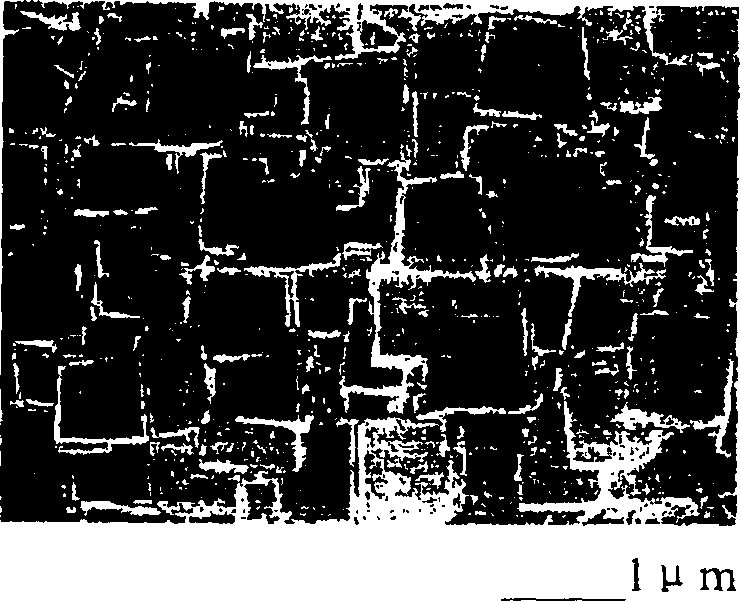

[0015] Example 1 Using microwave plasma chemical vapor deposition equipment to prepare (001) high-orientation diamond thin films is as follows: the monocrystalline silicon wafer as the substrate substrate is mirror-polished using a polishing technique commonly used in the semiconductor industry, and the surface of the monocrystalline silicon wafer The roughness is less than 2nm, and then ultrasonically cleaned in ethanol, acetone and deionized water for 10 minutes each, and dried the surface of the substrate with dried and purified nitrogen, and placed it in a 1.5KW microwave chemical vapor deposition device from ASTEX Corporation in the United States. + Method for preparing (001) highly oriented diamond film by ion etching diamond core. The specific process is as follows: Nucleation conditions: Plasma is formed, the pressure is controlled at 20 mbar, the substrate temperature is 1000 ℃, and CH is introduced. 4 And H 2 , H 2 Flow rate is 200sccm, CH 4 And H 2 The volume ratio is 7...

Embodiment 2

[0016]Embodiment 2 Another condition for preparing the (001) highly oriented film with microwave equipment is that the microwave equipment and the substrate processing are the same as in Embodiment 1. The pressure is controlled at 30mbar, the substrate temperature is 700℃, and CH is passed through 4 And H 2 , H 2 Flow rate is 100sccm, CH 4 And H 2 The volume ratio is 3%, and the microwave power is 700W. After the above parameters are stable, apply a DC bias voltage of -100V, control the nucleation time to 25 minutes, and make the diamond nucleation density 10 9 / cm 2 about. Then, turn off the bias voltage, CH 4 And H 2 , Evacuated to 10 -2 mbar, remove residual CH 4 , And then fill it with 300sccm of H 2 , Keep the pressure at about 30mbar, the substrate temperature at 700℃, and the microwave power at 700W. After the above parameters are stabilized, apply a bias voltage of -60V, and use the formed H + The ion etches the diamond core on the surface of the substrate, and the etching...

Embodiment 3

[0017] Embodiment 3 Another condition for preparing a (001) highly oriented film with microwave equipment is that the microwave equipment and the substrate processing are the same as in Embodiment 1. The pressure is controlled at 23mbar, the substrate temperature is 800℃, and CH is passed through 4 And H 2 , H 2 The flow rate is 150sccm, CH 4 And H 2 The volume ratio is 5%, and the microwave power is 900W. After the above parameters are stable, apply a DC bias voltage of -140V, control the nucleation time to 20 minutes, and make the diamond nucleation density 10 9 / cm 2 about. Then, turn off the bias voltage, CH 4 And H 2 , Evacuated to 10 -2 mbar, remove residual CH 4 , And then fill with 500sccm of H 2 , Keep the pressure at about 23mbar, the substrate temperature at 800°C, and the microwave power at 900W. After the above parameters are stabilized, apply a bias voltage of -120V, and use the formed H + The ions etch the diamond core on the surface of the substrate, and the etchin...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| surface roughness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com