Torque mirror driver of micro electromechanical system, producing method and use

A technology of micro-electro-mechanical systems and manufacturing methods, applied in the direction of generators/motors, relays, electromagnetic relays, etc., can solve the problems of increasing the difficulty of manufacturing processes, large polarization-related losses, and increased power consumption of devices, achieving high reliability, Effect of low optical insertion loss and low driving voltage

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

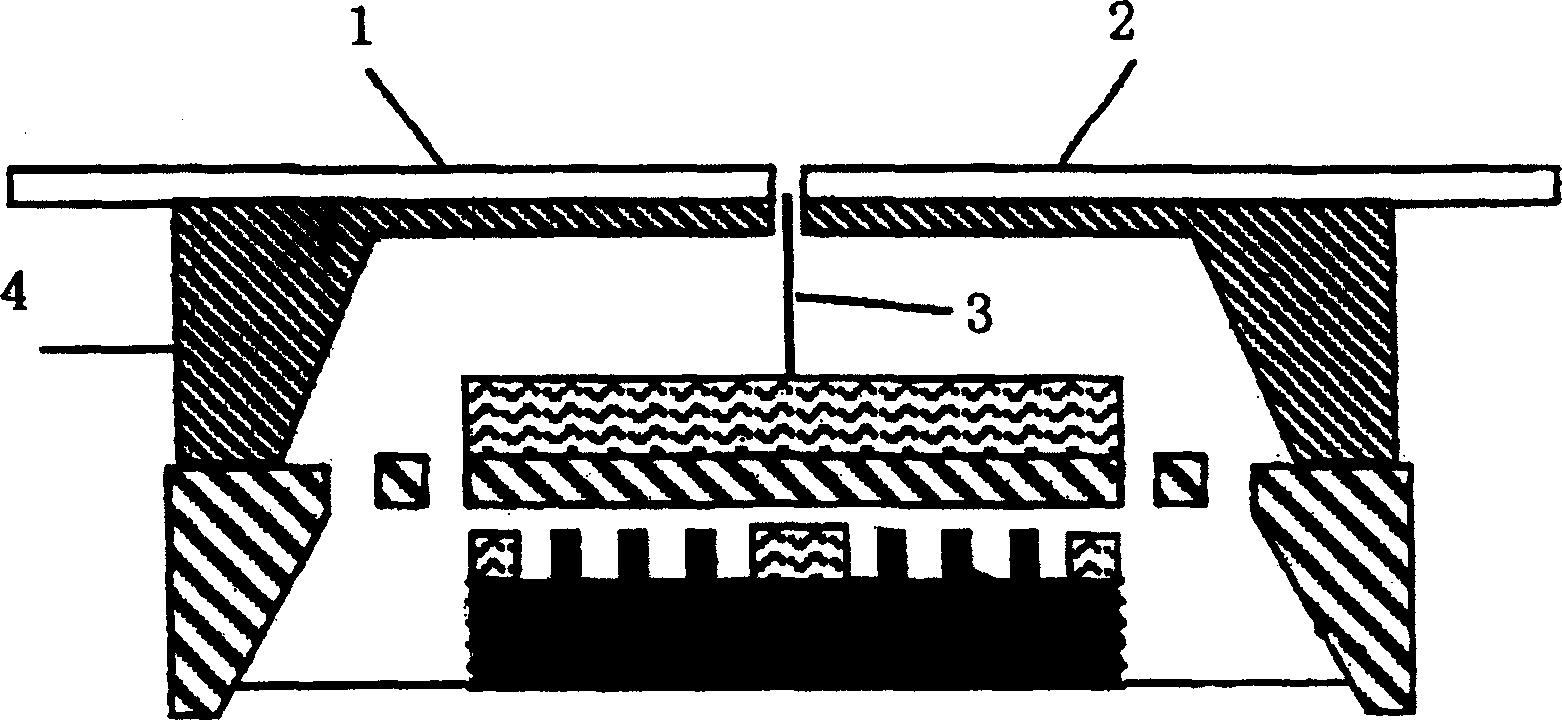

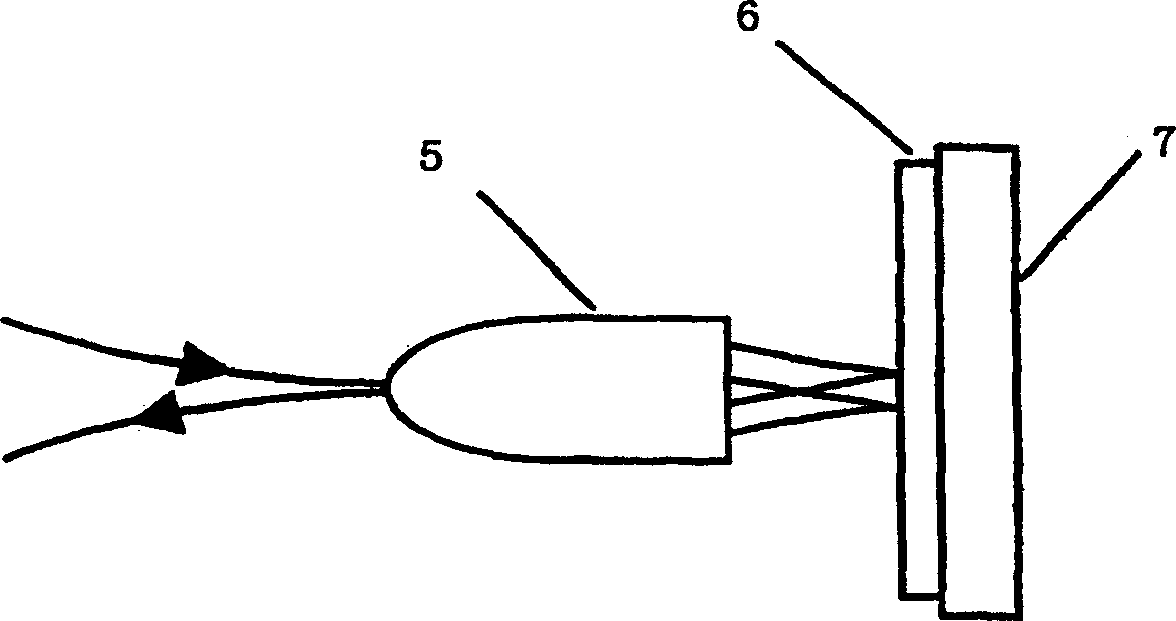

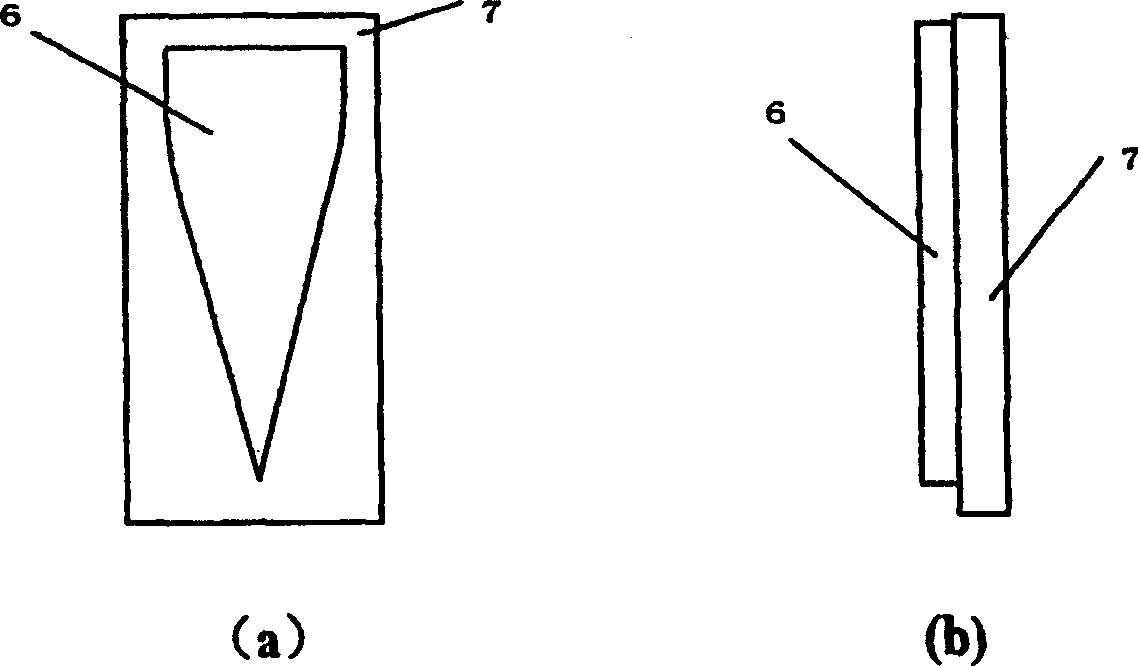

[0033] The manufacturing process steps of the MEMS twisted mirror provided by the present invention will be further explained below in conjunction with the accompanying drawings, so as to describe the specific structure of the twisted mirror driver provided by the present invention and its application as an adjustable optical attenuator.

[0034] Concrete implementation steps of the present invention are as follows:

[0035] 1. A silicon dioxide film with a thickness of about 1000 angstroms to 5000 angstroms is grown on the upper surface and the back side of the silicon wafer. Such as Figure 4 (b) shown.

[0036] 2. Use the photolithography, development and silicon dioxide etching process in MEMS technology to make the desired pattern on the silicon dioxide film. Such as Figure 4 (c) shown.

[0037]3. Put the silicon chip into the potassium hydroxide solution or TMAH solution with a solution concentration of 40% and a temperature of 40°C. The pattern on the back of the s...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com