Process for preparing Si base Bi4 Ti3 O12 ferroelectric film

A preparation process and technology of ferroelectric thin films, which are used in the manufacture/assembly of piezoelectric/electrostrictive devices, circuits, electrical components, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 2

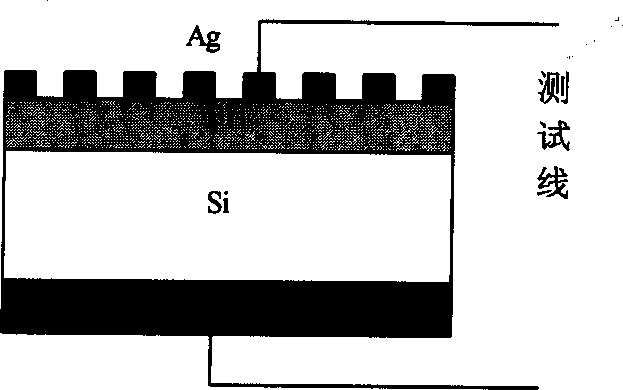

[0065] In order to test the electrical properties of the sample, it is necessary to prepare an upper electrode (ie, an Ag electrode) on the surface of the prepared ferroelectric thin film sample. Electrodes were prepared by DC magnetron sputtering process. During the preparation, a self-made stainless steel sheet mask is used to cover the ferroelectric thin film. There are many small holes with a diameter of 0.4 mm on the mask, and the required electrodes can be obtained on the surface of the thin film by magnetron sputtering. The sputtering power is about 70W, and the background vacuum is 3×10 -3 Pa and Ar atmosphere were sputtered under 20Pa pressure for one minute, and the thickness of the electrode was about 50nm. Then prepare the bottom full electrode (ie Pt electrode) on the back of the Si substrate by the same process as the upper electrode. The above preparation process is as figure 1 As shown, the cross-sectional view of the prepared test sample is shown in figur...

Embodiment 3

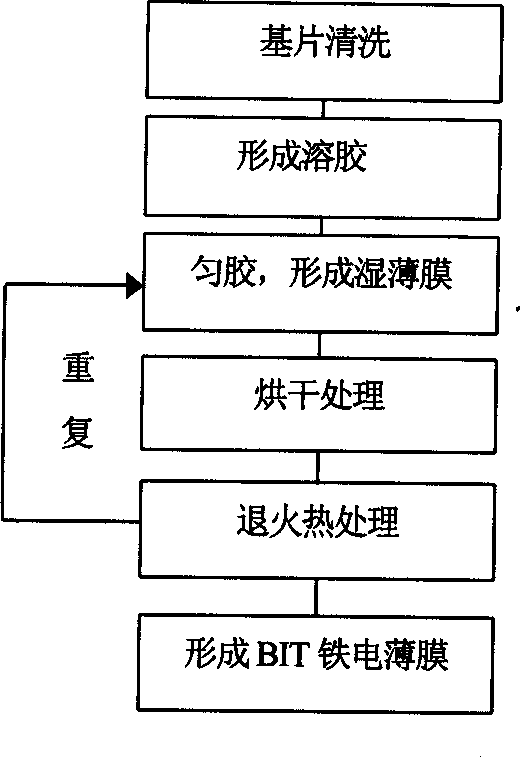

[0079] (2.9) filter to get Bi 4 Ti 3 o 12 Precursor solution; (3) the prepared Bi 4 Ti 3 o 12 Use a dropper to drop 1-2 drops of the precursor solution onto the substrate, start the homogenizer to homogenize the glue, and form a wet film; (5) Dry the well-distributed wet film on a constant temperature hot plate at 200°C, Removing C and H components in the wet film; (5) putting the dried film into a quartz tube furnace for annealing and taking it out. Annealing is carried out under oxygen atmosphere, and annealing temperature is 700 ℃, and oxygen (analytical purity 99.9%) flow rate is 2 liters / minute during annealing, and the annealing time of step 5 is 5 minutes; (6) repeat above-mentioned steps 3-5 eight times, A BIT ferroelectric thin film with a thickness of about 850nm can be obtained. (7) Finally, annealing is carried out in an oxygen atmosphere. The annealing temperature is 700° C., the flow rate of oxygen (analytical purity 99.9%) is 2 liters / minute during anneali...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Resistivity | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

| Diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com