SiGe/Si Chemical vapor deposition growth process

A chemical vapor deposition, silicon germanium technology, applied in electrical components, semiconductor/solid-state device manufacturing, circuits, etc., can solve the problems of epitaxial material pollution, affecting the quality of epitaxial layers, low background vacuum, etc. Clear, reduce material interface unclear, improve the effect of crystal quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

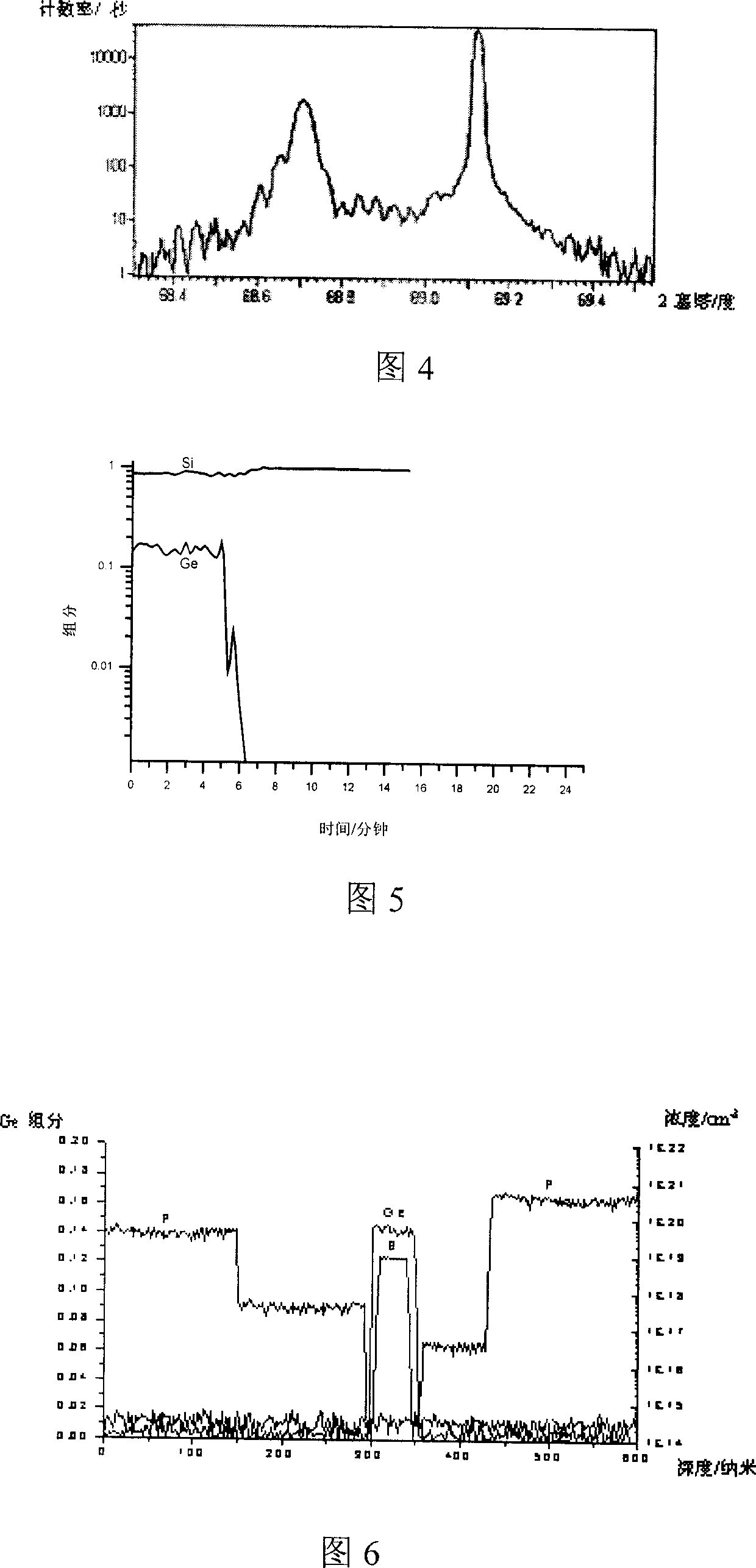

[0030] The present invention will be further described below through multiple examples realized on the novel photochemical vapor deposition equipment shown in FIG. 2 (this equipment has applied for a Chinese patent with application number 02262163.6).

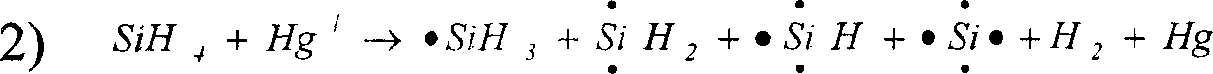

[0031] Example 1 grows a layer of intrinsic silicon germanium (SiGe) on the Si substrate 1-x Ge x ) material, its technical process is carried out according to the following steps:

[0032] Step 1: filling the processing chamber of the photochemical vapor deposition equipment with high-purity nitrogen to an atmospheric pressure. After the RCA treatment, the Si substrate is quickly placed in the high-purity nitrogen-protected processing chamber 3, and the processing chamber 3 is sealed;

[0033] Step 2: In the processing chamber 3, put the Si substrate into a 10% hydrofluoric acid (HF) solution through a sealed rubber glove, take it out after 30 seconds and put it into the substrate tray; at the same time, fill up the preparat...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com