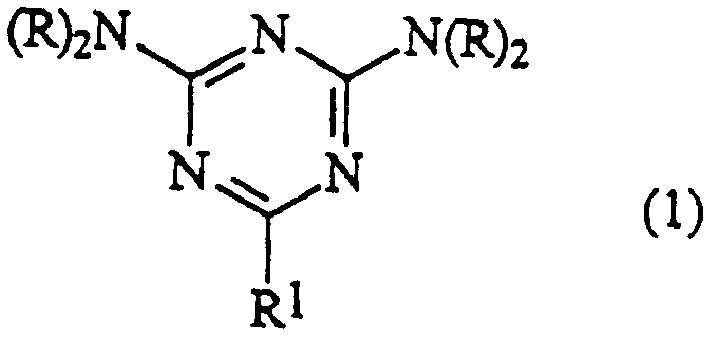

Flame-retarding nitrogenous epoxy resin and its composition

An epoxy resin and flame retardant technology, applied in the direction of organic chemistry, etc., can solve the problems of reducing the addition ratio and failing to improve the flame retardant properties of the resin composition, and achieve the effect of excellent heat resistance and excellent flame retardant effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Synthetic example 1

[0067] Hardening accelerator B: 2-methylimidazole (hereinafter referred to as 2MI). Synthesis Example 1 Preparation of Epoxy Resin D

[0068] Melamine 126g, 37% formaldehyde solution 240g and methanol 240g in 3 liter 5 neck glass equipped with electric heating mantle, temperature controller, electric mixer and stir bar, nitrogen inlet, electric thermocouple, water cooled condenser and addition funnel Heating, dissolving and stirring in the reaction kettle, stirring for 1 hour after the temperature reached 60°C. To the obtained mixture, 282 g of phenol and 1.3 g of hydrochloric acid were added, and the mixture was heated and stirred at a temperature of 80° C. for 4 hours to carry out a dehydration reaction. The above-mentioned reaction mixture is heated to reclaim methanol and water to obtain a triglyceride containing hydroxyl and phenyl. Compound 409 g, analyzed for nitrogen content of about 20.5%.

Synthetic example 2

[0069] The obtained hydroxy- and phenyl-containing tris 100 grams of the compound and 555 grams of epichlorohydrin were placed in a glass reactor for heating, stirring and dissolving. When the pressure reached 200 mmHg and the temperature reached 70°C by vacuuming and decompression, 49.5% aqueous sodium hydroxide solution of 77.9% was stably added within 4 hours. g, and continue to react for 1 hour. After completing the reaction, heating and recovering epichlorohydrin, adding a solvent and water to the residue, filtering the resin after removing the brine, and steaming off the solvent, the nitrogen-containing flame-retardant epoxy resin of the present invention (hereinafter referred to as epoxy resin) is obtained. Resin D) 138 grams, the nitrogen content of the epoxy resin obtained by analysis is about 14.9%, and the epoxy equivalent is about 205 g / ml. Synthesis example 2 Preparation of epoxy resin E

[0070] 126 g melamine, 486 g 37% formaldehyde in water and 486 g n-butan...

Synthetic example 3

[0071] The obtained hydroxy- and phenyl-containing tris 130 grams of compound and 555 grams of epichlorohydrin were placed in a glass reaction kettle for heating, stirring and dissolving. When the pressure reached 200 mmHg and the temperature reached 70 ℃ by vacuuming and decompression, 49.5% sodium hydroxide aqueous solution 77.9 ℃ was added stably within 4 hours. g, and continue to react for 1 hour. After completing the reaction, heating and recovering epichlorohydrin, adding a solvent and water to the residue, filtering the resin after removing the brine, and steaming off the solvent, the nitrogen-containing flame-retardant epoxy resin of the present invention (hereinafter referred to as epoxy resin) is obtained. Resin E) 182 grams, the nitrogen content of the epoxy resin obtained by analysis is about 7.8%, and the epoxy equivalent weight is about 235 grams / equivalent. Synthesis Example 3 Preparation of Phosphorus-Containing Epoxy Resin F

[0072] In a 3-liter 5-neck gla...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| epoxy equivalent | aaaaa | aaaaa |

| epoxy equivalent | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com