Composite fertilizer with special regulation effect and its production process

A technology of compound fertilizer and manufacturing method, which is applied in fertilizer mixtures, botanical equipment and methods, chemicals for biological control, etc., can solve the problems of easy degradation of crops, aging, decline in quality of agricultural products, and large amount of chemical fertilizer application. , to improve the quality of agricultural products, reduce insect pests, and increase the effect of biological growth.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

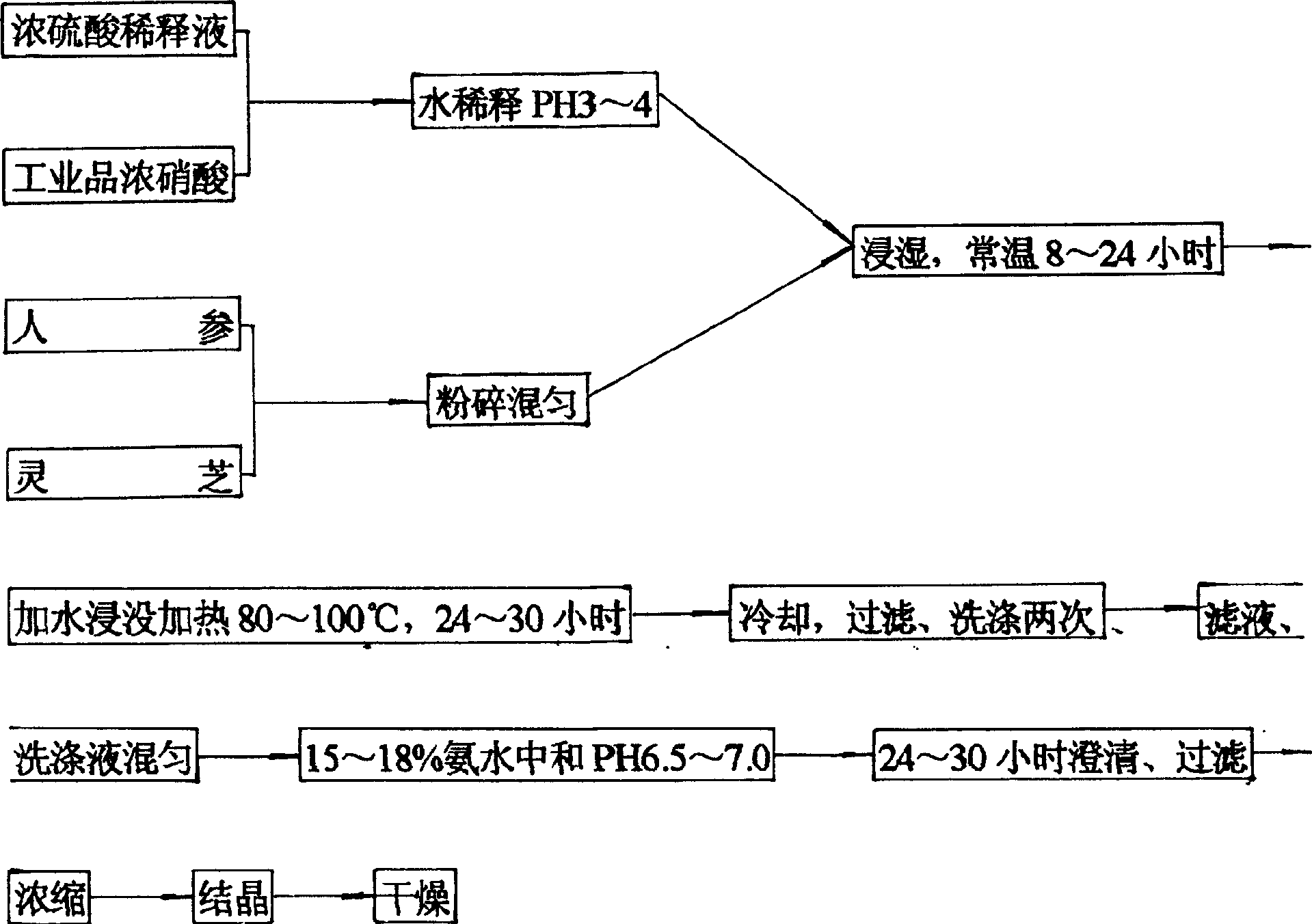

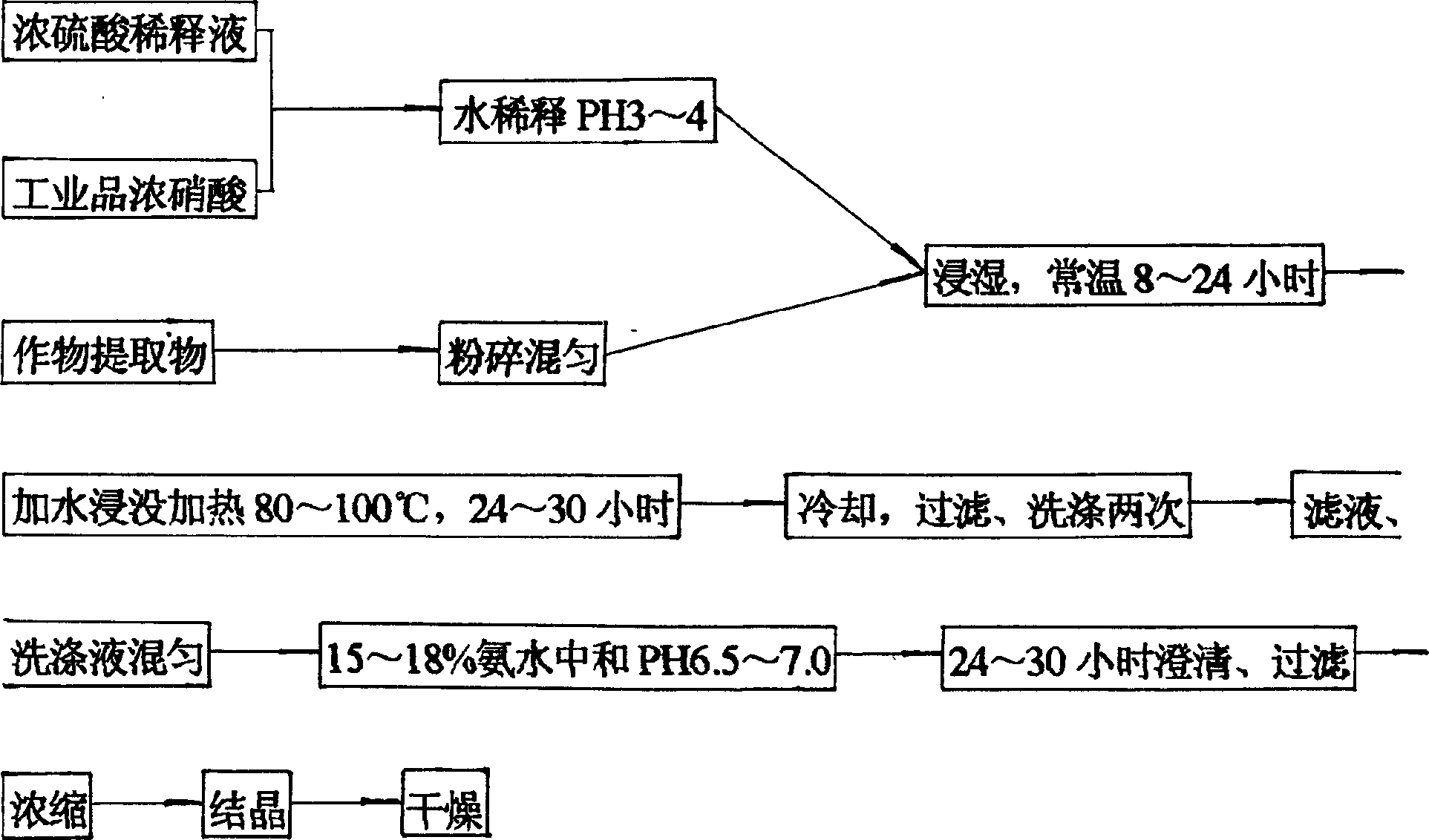

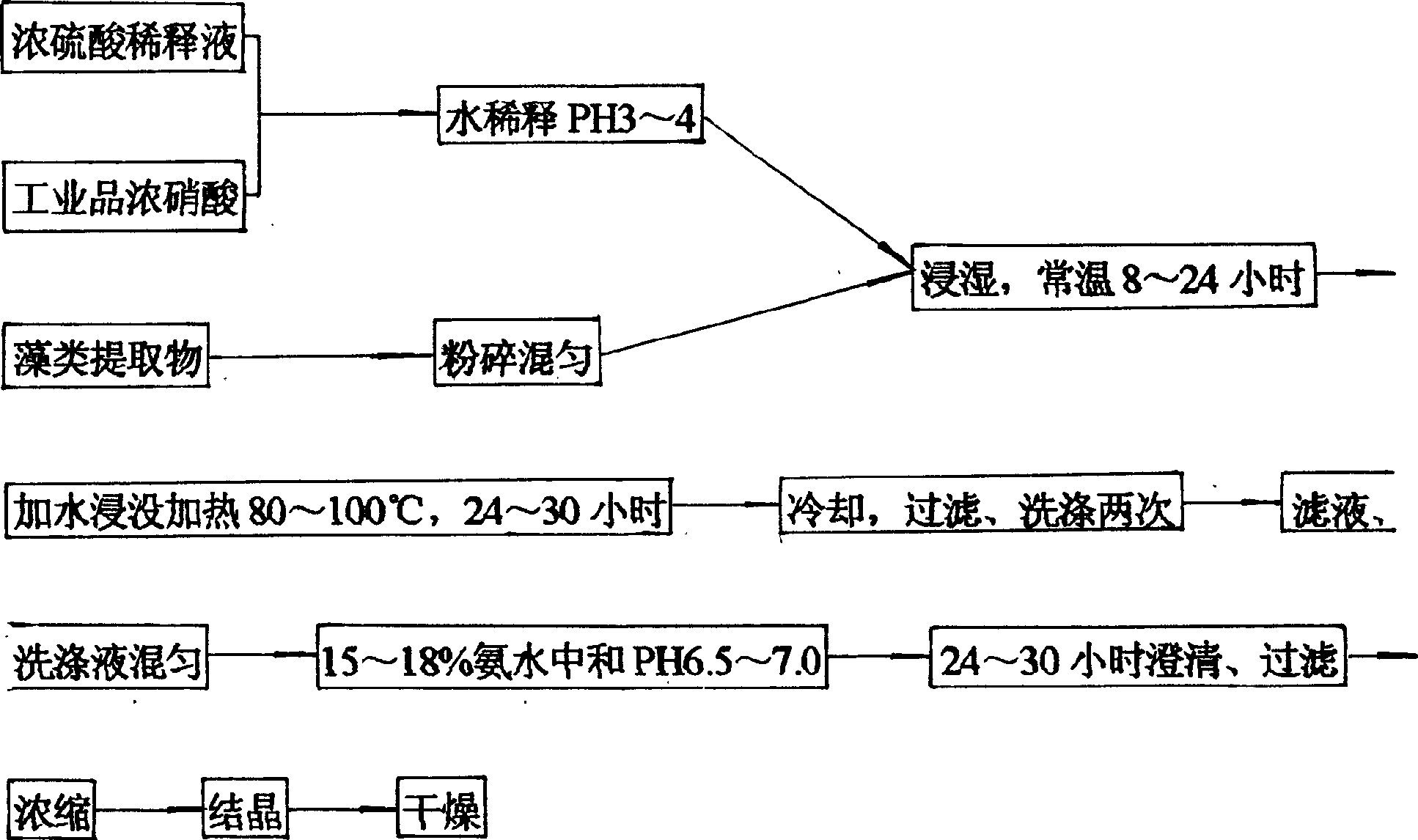

Method used

Image

Examples

Embodiment 1

[0012]Special effect compound fertilizer for grain crops is composed of 64% of compound fertilizer, 4% of special effect components and 32% of auxiliary materials. Among them, the large amount of nutrients in the compound fertilizer: 8% nitrogen, 8% phosphorus pentoxide, and 10% potassium oxide; the special effect components are: 1% ginseng ganoderma extract, 1% food crop leaf extract, algae extract 1%, lemon extract 1%: Secondary nutrient elements in the remaining auxiliary materials: sulfur 10%, magnesium 6%; micronutrient elements: iron 0.4%, manganese 0.2%, zinc 0.2%.

Embodiment 2

[0014] Special special-effect compound fertilizer for tobacco leaves is composed of 65% of compound fertilizer, 5% of special-effect components and 30% of auxiliary materials. Among them, the large amount of nutrients in the compound fertilizer; 8% nitrogen, 8% phosphorus pentoxide, and 10% potassium oxide; the special effect components are: 1% ginseng ganoderma extract, 22% tobacco leaf extract, 1% algae extract, Lemon extract 1%; Secondary nutrients in the remaining auxiliary materials: 10% sulfur, 7% magnesium; Micronutrients: 0.4% iron, 0.2% manganese, 0.2% zinc.

Embodiment 3

[0016] The special effect compound fertilizer for sugar cane increase is composed of 63% of compound fertilizer, 7% of special effect components and 30% of auxiliary materials. Among them, the large amount of nutrients in the compound fertilizer: 8% nitrogen, 10% phosphorus pentoxide, and 10% potassium oxide; the special effect components are: 2% of ginseng and ganoderma extract, 2% of sugarcane leaf extract, and 2% of algae extract , Lemon extract 1%; Secondary nutrient elements in the remaining auxiliary materials: Sulfur 13%, Magnesium 7%; Micronutrient elements: Iron 0.4%, Manganese 0.2%, Zinc 0.2%.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com