Nickel-hydrogen power battery

A power battery and nickel-metal hydride technology, which is applied in the field of high-power battery preparation, can solve the problems of high output power, high temperature resistance, low temperature resistance of the battery, which have not been reported, the battery high-power discharge performance is reduced, and can not work, etc. Small expansion, avoiding internal short circuit and excellent performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

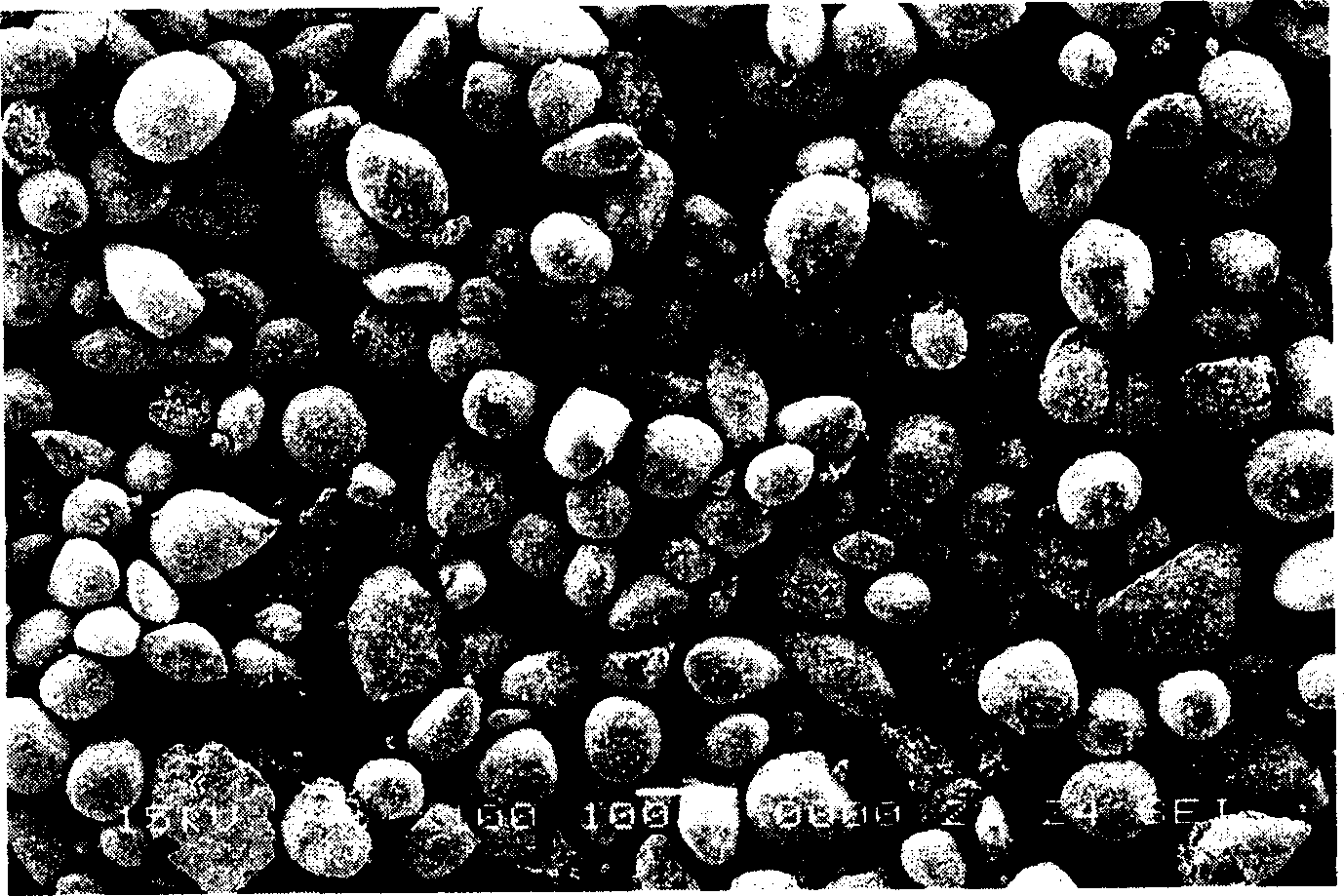

[0025] Positive active material spherical Ni(OH) 2 Preparation of composite materials with additives. The present invention adopts chemical precipitation crystal growth method to prepare spherical Ni(OH) 2 And add as Y 2 O 3 , CeO 2 , CoO, ZnO, TiO 2 , Yb 2 O 3 And other additives to make the positive electrode composite active material. Spherical Ni(OH) 2 Low density Ni(OH) with irregular shapes 2 In comparison, it has relatively high density and good filling fluidity. Therefore, spherical Ni(OH) is used 2 As an active material, it can increase the filling amount per unit volume of the electrode, thus increasing the electrode capacity accordingly.

[0026]Add Y 2 O 3 , CoO and Yb 2 O 3 (Mass ratio 1: 1: 1) spherical Ni(OH) 2 , The mass ratio of the additive amount is 4%.

[0027] In the preparation process, nickel sulfate, sodium hydroxide, ammonia and metered additives are generally selected as raw materials; NiSO 4 The relative density of the solution is controlled at 1.05g / cm ...

Embodiment 2

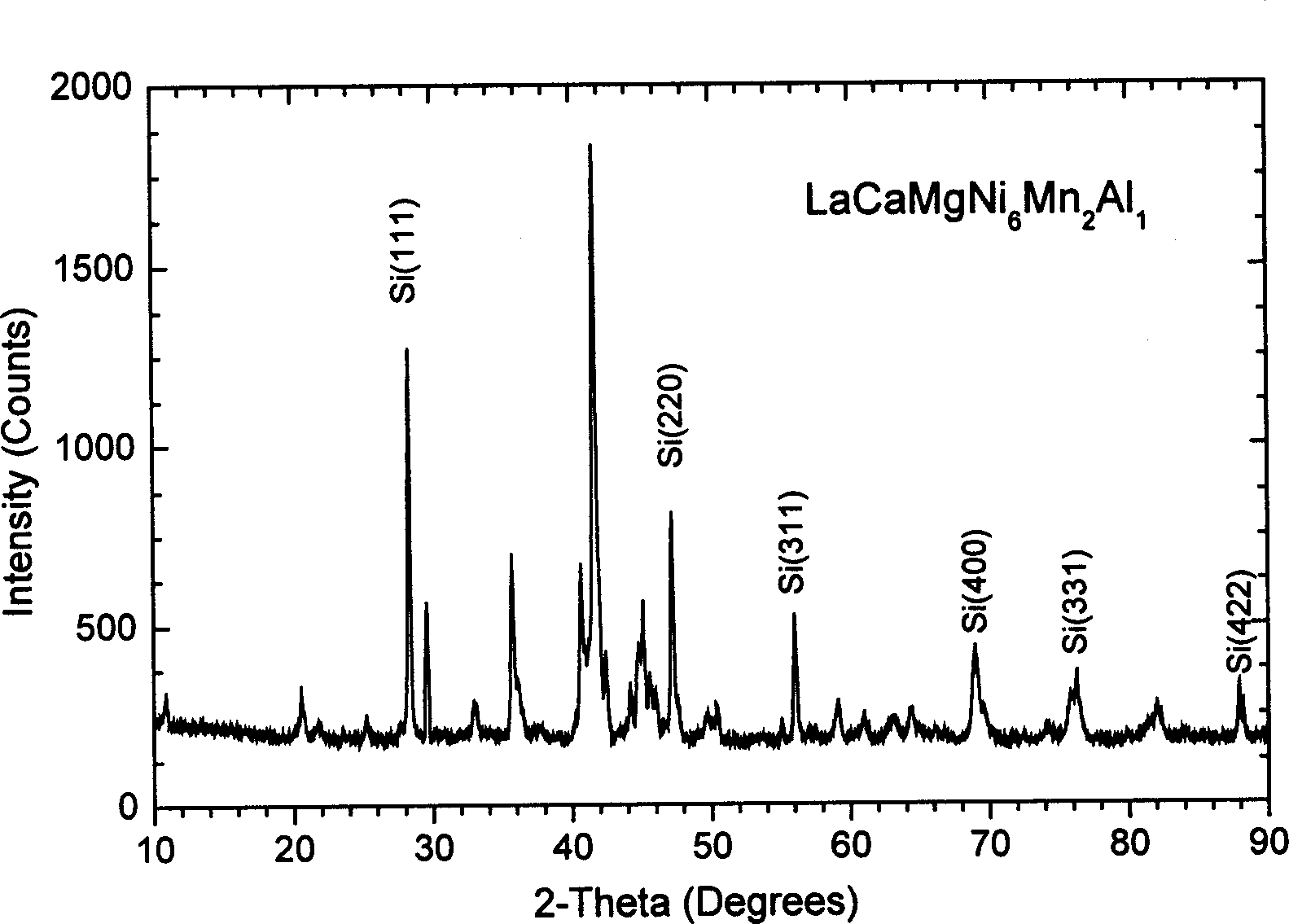

[0029] AB 3 Preparation of a new type of hydrogen storage alloy. AB 3 Type alloy structure contains AB 5 And AB 2 Unit, such as AB 5 +2AB 2 = 3AB 3 . LaCaMgNi 6 Mn 2 Al i As an example, the X-ray diffraction analysis with silicon powder is as figure 2 As shown, figure 2 For AB 3 X-ray diffraction analysis of new hydrogen storage alloy and silicon powder. Because of AB 3 The c-axis of the alloy lattice is long, and it can contain Mm, Ca, Mg, Ti on the A side, so the theoretical hydrogen storage capacity can reach 500mAh / g, and the actual measurement can generally reach 360-420mAh / g, and the price is relatively It is inexpensive and has good cycle life. In the alloy preparation process, first melt the volatile metals Ca and Mg with Al to prepare a master alloy, and then add other components in a vacuum induction furnace (1200°C) for induction smelting, and in a water-cooled copper crucible Casting into alloy ingots. Under the protection of argon, the alloy ingot is crushed into al...

Embodiment 3

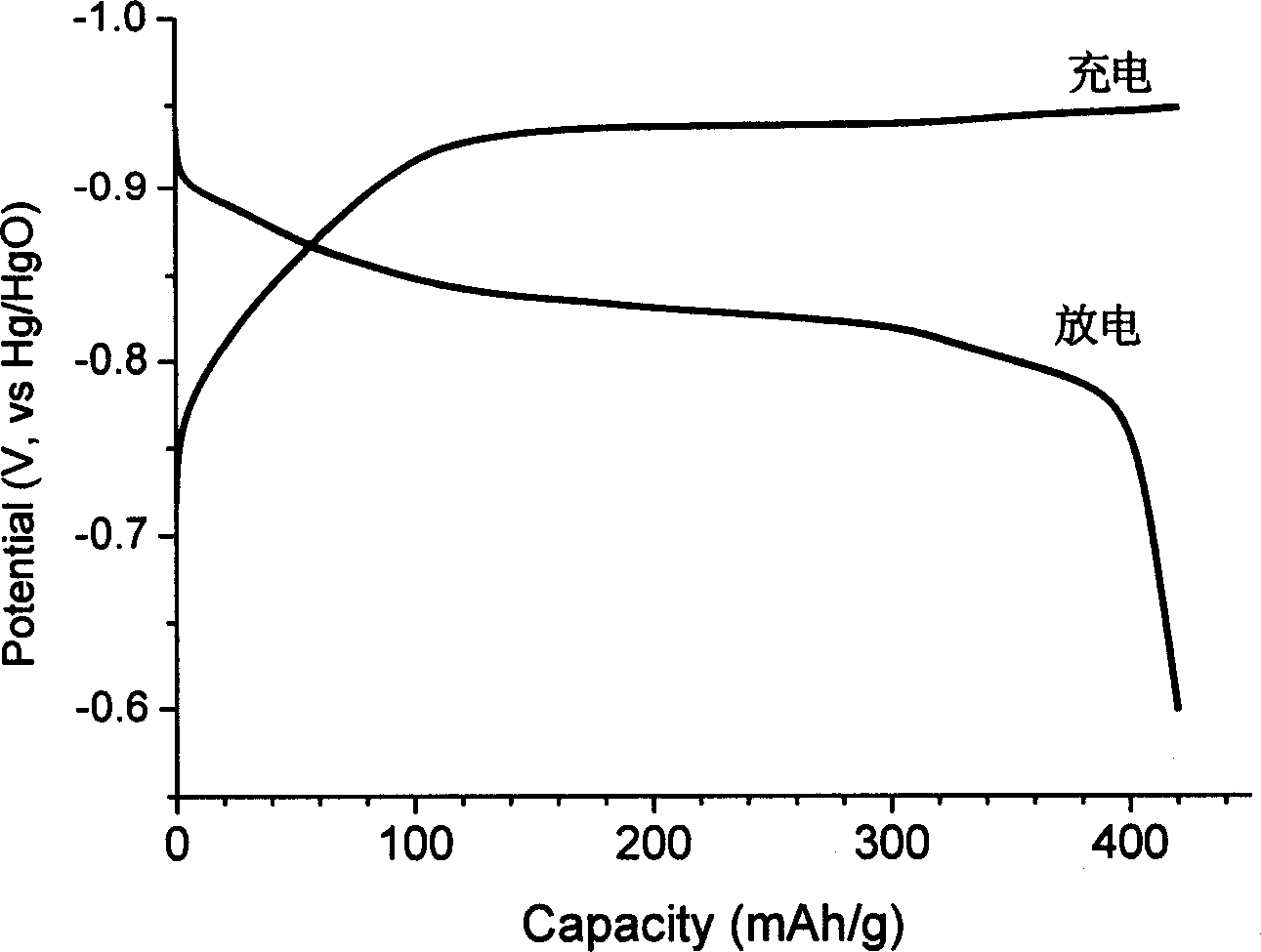

[0032] MmCaMgNi 6 Co 1 Mn 1 Al 1 Alloy electrode. See Example 2 for specific operation steps. Add C 60 , BN and Y 2 O 3 (Mass ratio 1: 1: 1) MmCaMgNi 6 Co 1 Mn 1 Al 1 In the alloy electrode, the mass ratio of additives is 4%. The prepared electrode has excellent charge and discharge performance, see image 3 , image 3 C added for 4% 60 , BN and Y 2 O 3 MmCaMgNi 6 Co 1 Mn 1 Al 1 Electrode charge and discharge curve.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Diameter | aaaaa | aaaaa |

| Height | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com