Lithium ion battery for walkie-talkie and producing method thereof

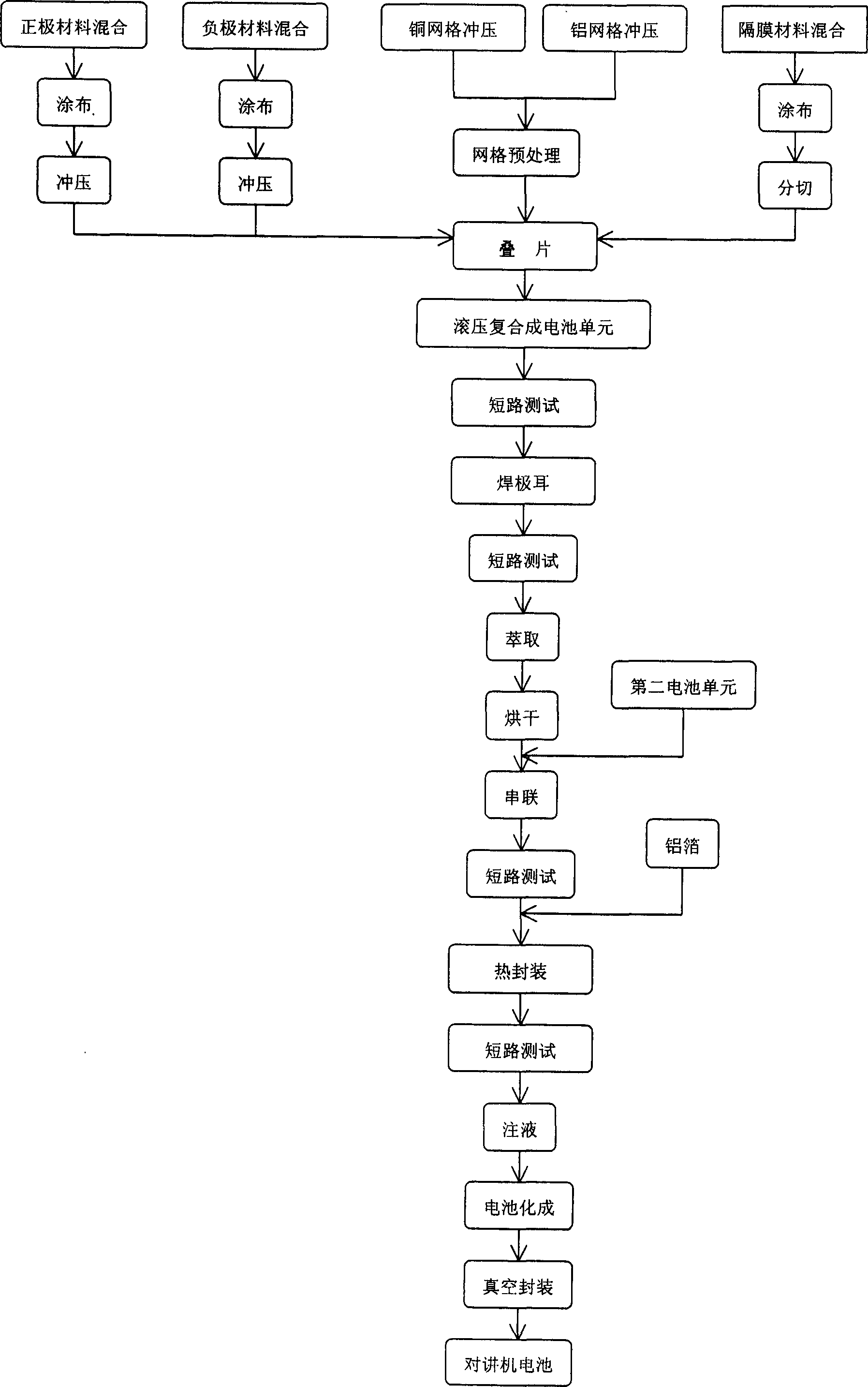

A lithium-ion battery, walkie-talkie technology, applied in the manufacture of electrolyte batteries, secondary batteries, non-aqueous electrolyte batteries, etc., can solve the problems of short talk and standby time, complex production process, low battery specific energy, etc., and achieve high yield , The effect of simple process and low product cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0009] Embodiment one. By LiCoO 2 67%, Li 2 CO 3 1%, conductive carbon black 6%, PVDF and PMMA blend (blending ratio PVDF / PMMA=4 / 1) 12%, dibutyl ester DBP or dimethylethylene DME 14%, while adding acetone as organic Solvent, stir evenly to make positive electrode material slurry; press MCMB85%, conductive carbon black 5%, PVDF and PMMA blend (blending ratio PVDF / PMMA=4 / 1) 5.5%, dibutyl ester DBP or dimethyl Ethylene DME4.5% ratio is mixed, add acetone simultaneously as organic solvent, stir and make anode material slurry; Press PVDF and PMMA blend (blending ratio PVDF / PMMA=4 / 1) 45%, gas phase Silicon 5%, dibutyl ester DBP or dimethyl ethylene DME 50% mixed, at the same time add acetone as an organic solvent, stir evenly to make diaphragm material slurry; according to (mass percentage) polymer hot melt 80%, methanol or ethanol 15%, conductive carbon black 5% mixed, stirred evenly to make grid pretreatment material slurry; according to conductive salt LiPF 6 1 mole / liter, m...

Embodiment 2

[0010] Embodiment two. The composition of the positive electrode material is (mass ratio) LiCoO 2 67%, Li 2 CO 3 1%, conductive carbon black 6%, PVDF and PMMA blend (blending ratio PVDF / PMMA=4 / 1) 12%, dimethylethylene DME14%; The composition of negative electrode material is (mass ratio) MCMB85%, conductive Carbon black 5%, PVDF and PMMA blend (blending ratio PVDF / PMMA=4 / 1) 5.5%, dimethylethylene DME 4.5%; the composition of the diaphragm material is (mass ratio) PVDF and PMMA blend (Blending ratio PVDF / PMMA=4 / 1) 45%, fumed silica 5%, dimethylethylene DME 0%; the composition of grid pretreatment material is (mass percentage) macromolecule thermal sol 80%, methanol Or ethanol 15%, conductive carbon black 5%; The composition of electrolytic solution is (mass ratio) conductive salt LiClO 4 1 mol / liter, and the rest of the plasticizer, the plasticizer is a mixture of EC:DEC=1:1 (volume). Others are the same as embodiment one.

Embodiment 3

[0011] Embodiment three. The composition of the electrolyte is (mass ratio) conductive salt LiAsF 6 1 mol / liter, and the rest of the plasticizer, the plasticizer is a mixture of EC:DME=1:1 (by volume). Others are the same as embodiment two.

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap