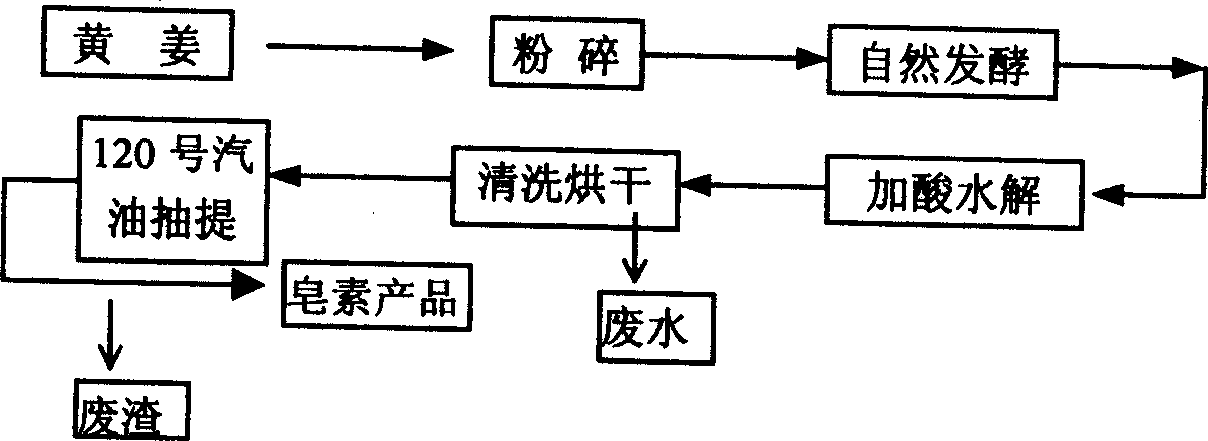

Process for extracting saporin by direct separation method

A separation method and saponin technology, applied in the field of phytochemical engineering, can solve the problems of serious pollution, low recovery rate of saponin, low recovery rate and the like

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

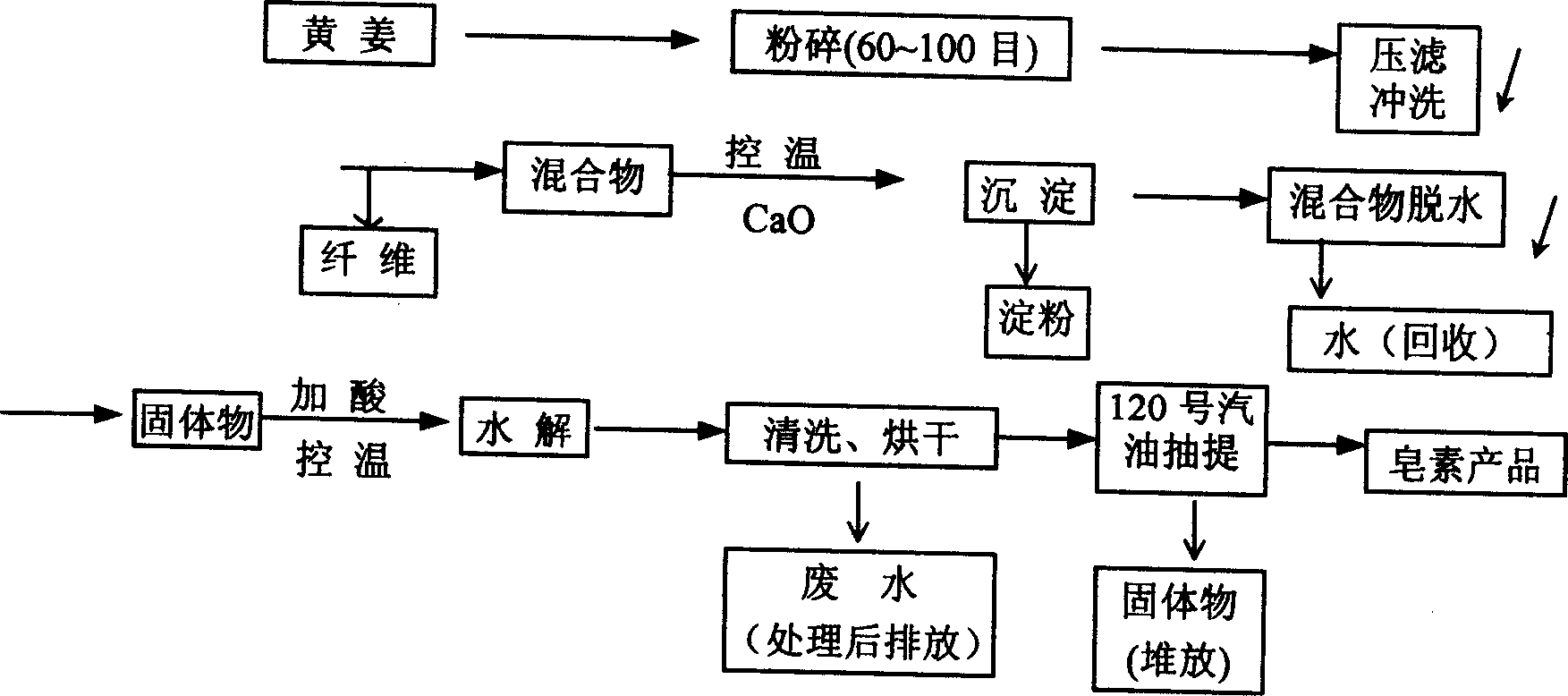

[0031] The process of extracting saponin from turmeric by direct separation method is realized by the following steps: 1) Pulverization: take turmeric, wash and pulverize it, and after the turmeric is pulverized, it is ground to 60-100 mesh with water; 2) Separation: a. Sieve 60-100 mesh turmeric, and use a rotary leaf filter press with 110-130 mesh to separate the fibers; b. Add CaO to the remaining mixture at 10-25°C, settle for 2-4 hours, and divide the mixture into upper and lower Two layers, the lower layer is starch, the upper layer is a mixture containing soap, and the starch is separated; 3) Saponin extraction: the saponin mixture is naturally fermented for 2-4 days, then boiled and hydrolyzed with 2M hydrochloric acid for 3-5 hours, and the acid solution is filtered off. Add CaO to neutralize to neutral, wash, dehydrate and dry, and then use No. 120 gasoline or ethanol or acetone or supercritical CO 2 Extract to get saponin.

[0032] The main equipment for industrial...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com