Method of polymerization and coagulation for treating sewage participating of heavy concentration acrylonitrile

An acrylonitrile wastewater, high concentration technology, applied in the direction of flocculation/sedimentation water/sewage treatment, etc., can solve the problems of incomplete treatment, high cost of wastewater treatment, lack of pretreatment technology, etc., to achieve good treatment effect, low treatment cost, Reasonable effect of craftsmanship

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

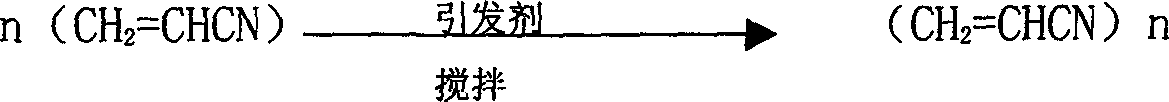

Method used

Image

Examples

Embodiment 1

[0011] This implementation takes the configured high-concentration acrylonitrile wastewater as an example

[0012] Use acrylonitrile (chemically pure reagent) and distilled water to prepare acrylonitrile wastewater with a certain concentration. Take 500ml of waste water and put it in a 1000ml beaker, add a small amount (0.05‰-8‰) of solid analytically pure ammonium persulfate, and react with electromagnetic stirring at 35±2°C for 30-180 minutes. Cool to room temperature, adjust the pH of the wastewater to 7-8 with solid NaOH, then add 0.5% polyaluminium chloride (10% aqueous solution) for coagulation, and let stand to precipitate water. The processing effect detection is as follows:

[0013] Table 1 ammonium persulfate as the acrylonitrile removal effect of initiator

[0014] Response time (minutes) 0 30 45 60 75 90 105 120 150 180

[0015] Waste water quality CODcr 7603 5447 3764 3468 1627 507 494 466 136 85

[0016] (Unit: mg / l)

[0017] Wastewater kCODc...

Embodiment 2

[0024] Use acrylonitrile (chemically pure reagent) and distilled water to prepare acrylonitrile wastewater with a certain concentration. Take 500ml of waste water and put it in a 1000ml beaker, add a small amount (0.05‰-8‰) of solid analytically pure potassium persulfate, and stir electromagnetically at 35±2°C for 30-180 minutes. Cool to room temperature, adjust the pH of the wastewater to 7-8 with solid NaOH, then add 0.5% polyaluminium chloride (10% aqueous solution) for coagulation, and let stand to precipitate water. The processing effect detection is as follows:

[0025] Table 2 Potassium persulfate as the acrylonitrile removal effect of initiator

[0026] Response time (minutes) 0 30 45 60 75 90 105

[0027] Waste water quality CODcr 7603 4299 3216 1764 1012 496 192

[0028] (Unit: mg / l)

[0029] Removal % / 39 58 77 86 93 97

Embodiment 3

[0031] Use acrylonitrile (chemically pure reagent) and distilled water to prepare acrylonitrile wastewater with a certain concentration. Take 500ml of waste water and put it in a 1000ml beaker, add a small amount (0.05‰-8‰) of solid analytically pure sodium chlorate, and stir electromagnetically at 35±2°C for 30-180 minutes. Cool to room temperature, adjust the pH of the wastewater to 7-8 with solid NaOH, then add 0.5% polyaluminium chloride (10% aqueous solution) for coagulation, and let stand to precipitate water. The processing effect detection is as follows:

[0032] Table 3 Sodium chlorate is as the acrylonitrile removal effect of initiator

[0033] Response time (minutes) 0 30 45 60 75 90 105

[0034] Waste water quality CODcr 7603 5143 4583 3995 2302 1247 578

[0035] (Unit: mg / l)

[0036] Removal % / 32 40 47 70 84 92

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com