Method of raising the stability of isobutene polymer slurry

A technology of isobutylene polymer and slurry method, which is applied in the field of improving the stability of isobutylene polymer slurry, and can solve problems such as aggregation and agglomeration, increased cost, and adverse effects of isobutylene polymer production

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

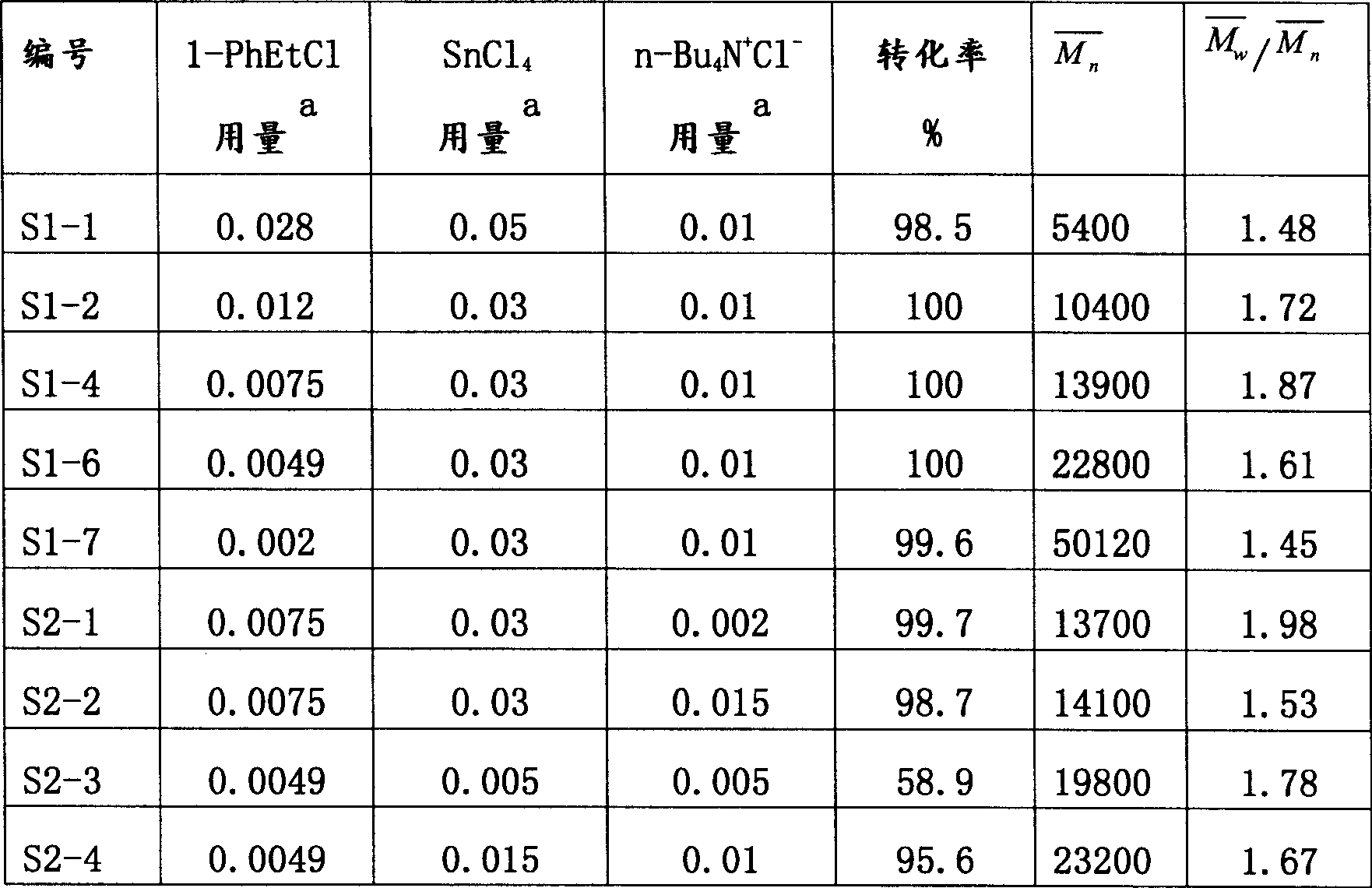

[0031] Example 1 Preparation of slurry stabilizer precursor by cationic polymerization of p-methylstyrene monomer in methylene chloride:

[0032] Polymerization was carried out in a 100 ml tubular reactor. The reactor is first baked under vacuum, filled with nitrogen, and repeated several times. Then the reactor was placed in a cold bath, and a metered amount of initiator 1-phenylchloroethane (1-PhEtCl), additive n-Bu 4 N + Cl - , the monomer p-methylstyrene (pMSt) and the solvent methylene chloride. After the temperature reaches the predetermined reaction temperature, add the co-initiator SnCl 4 The polymerization reaction is started. After reacting for a predetermined time, the polymerization reaction is terminated with pre-cooled methanol to obtain a stabilizer precursor. After the monochloromethane volatilized, a certain amount of dichloromethane was added to dissolve the polymer, and then precipitated with methanol, filtered, vacuum-dried, weighed, and the conversio...

Embodiment 2

[0036] Example 2 Preparation of slurry stabilizer precursor by cationic polymerization of styrene monomer in methylene chloride:

[0037] Get a well-processed polymerization reactor as described in Example 1, place it in a cold bath, then add 20 milliliters of solvent monochloromethane, 3 milliliters of monomeric styrene, 28 milligrams of additives tetrabutylammonium bromide ( Consumption is 1% of styrene monomer quality), 25 microliters of initiator cumyl oxygen (consumption is 0.9% of styrene monomer quality), above-mentioned reactant is cooled to-80 ℃, then adds 75 microliters of co- Initiator SnCl4 (The consumption is 6% of the mass of styrene monomer), and the polymerization reaction starts. After 1 hour of reaction, methanol was added to terminate the reaction. Get about 1.08 grams of polystyrene (conversion rate about 40%), relative molecular mass =6500, relative molecular mass distribution index =1.53.

Embodiment 3

[0038] Example 3 Stabilization of Isobutylene Polymer Slurry by Indirect Addition of Stabilizer Precursor

[0039] Polymerization experiments of isobutylene copolymers were carried out in a 250 ml stirred tubular reactor. With 30 milliliters of diluent methylene chloride, 21 gram monomer isobutylene, 0.8 gram comonomer isoprene, 0.160 gram polyp-methylstyrene (numbering S1-4 in embodiment 1, relative molecular mass =13900, relative molecular mass distribution index =1.87, the dosage is about 0.75% of the monomer weight) into the reactor and cooled to -95°C. Then add 25 ml of AlCl 3 Chloromethane solution (which contains AlCl 3 about 18 mg). During the polymerization, the temperature inside the reactor rose to -75°C. The material in the reactor is a milky white dispersion, and there is no adhering polymer on the reactor wall, stirring blade and stirring shaft. After the agitation was stopped, no polymer agglomeration in the reactor was observed within 10 minutes. The c...

PUM

| Property | Measurement | Unit |

|---|---|---|

| degree of unsaturation | aaaaa | aaaaa |

| degree of unsaturation | aaaaa | aaaaa |

| degree of unsaturation | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com