Method for fabricating ferroelectric random access memory device

A technology of random access memory and manufacturing method, applied in static memory, digital memory information, capacitors, etc., can solve the problems of oxygen diffusion, oxidation of titanium nitride layer, increase of leakage current, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0037] Hereinafter, details of preferred embodiments of the present invention will be described with reference to the accompanying drawings.

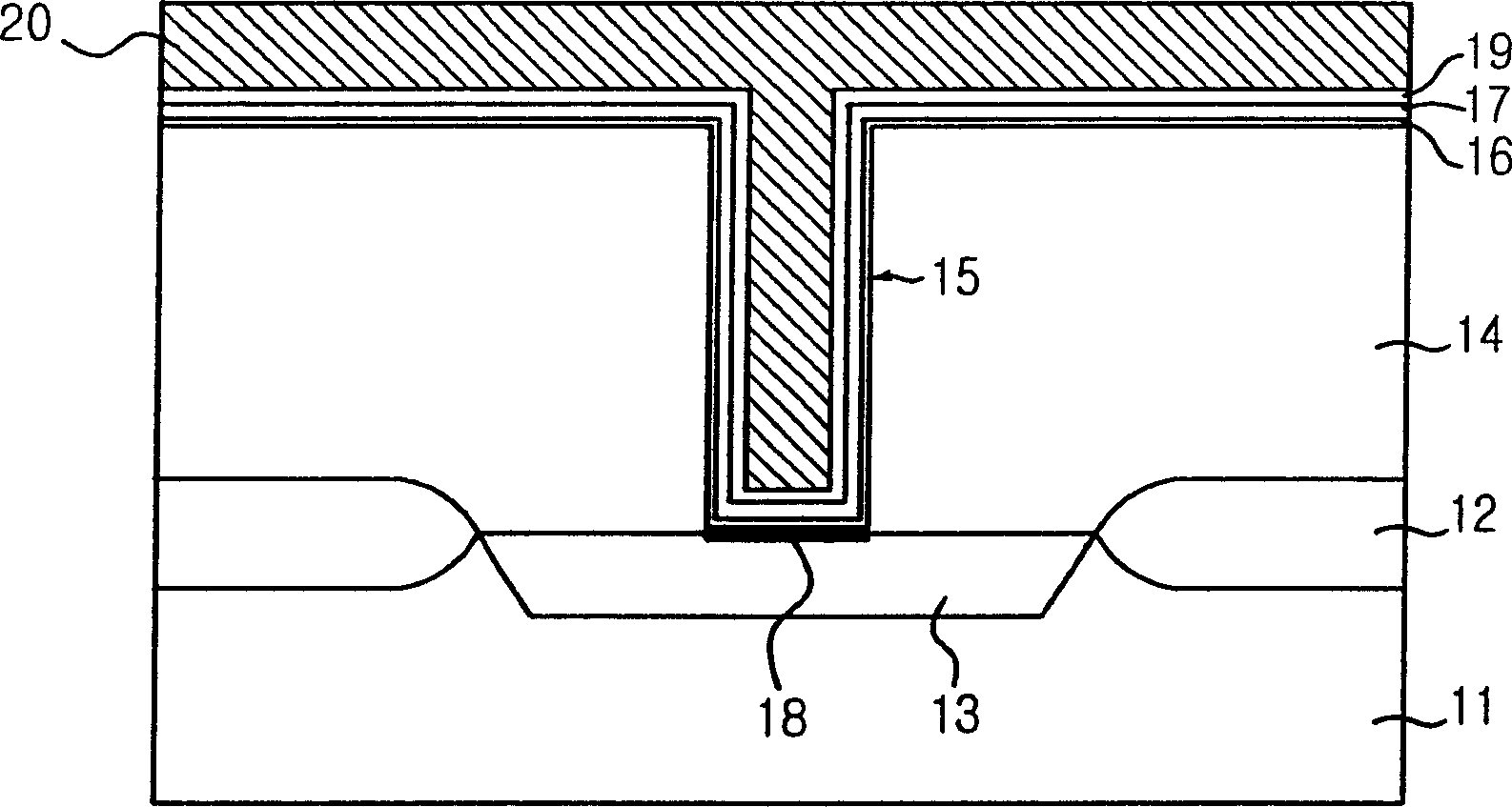

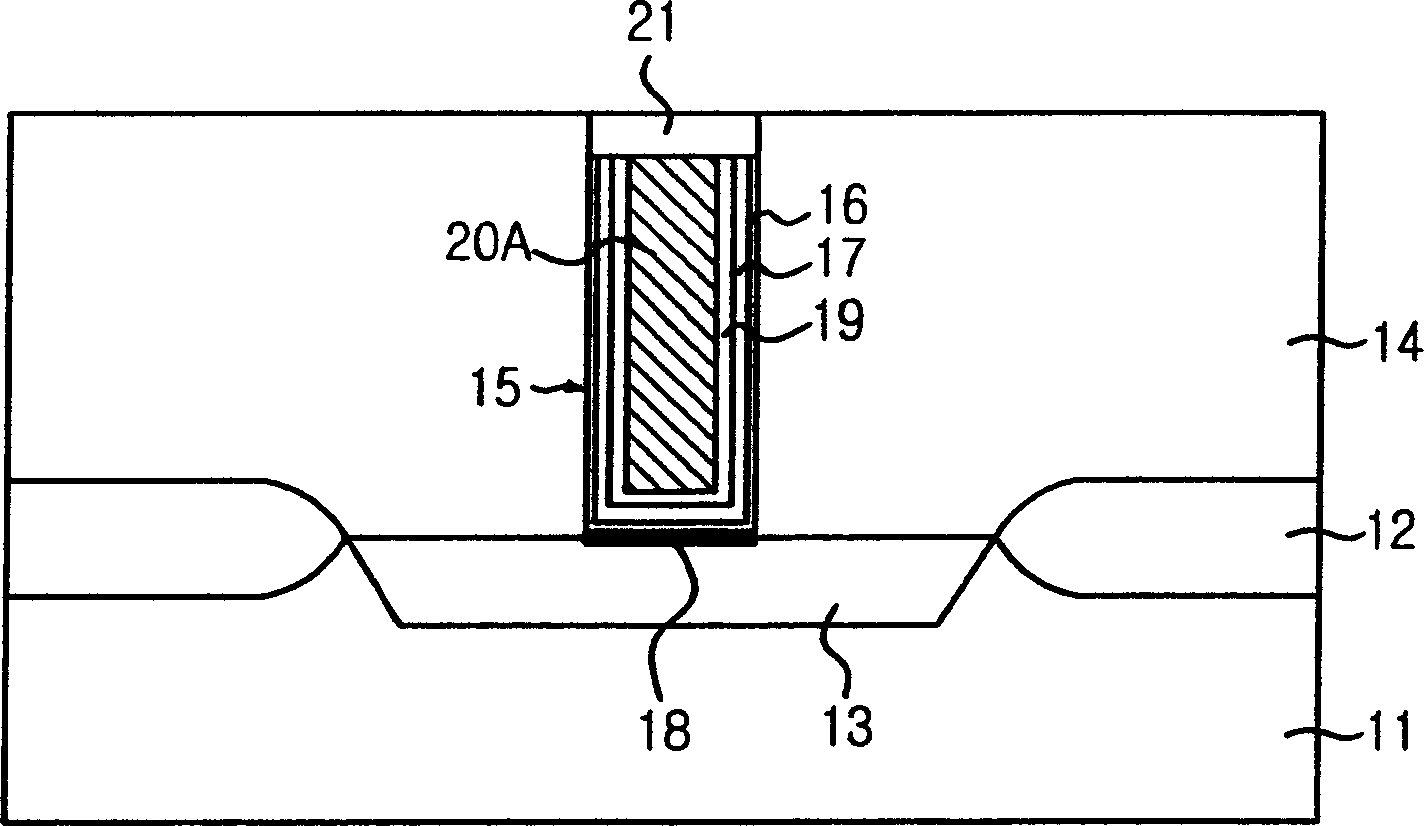

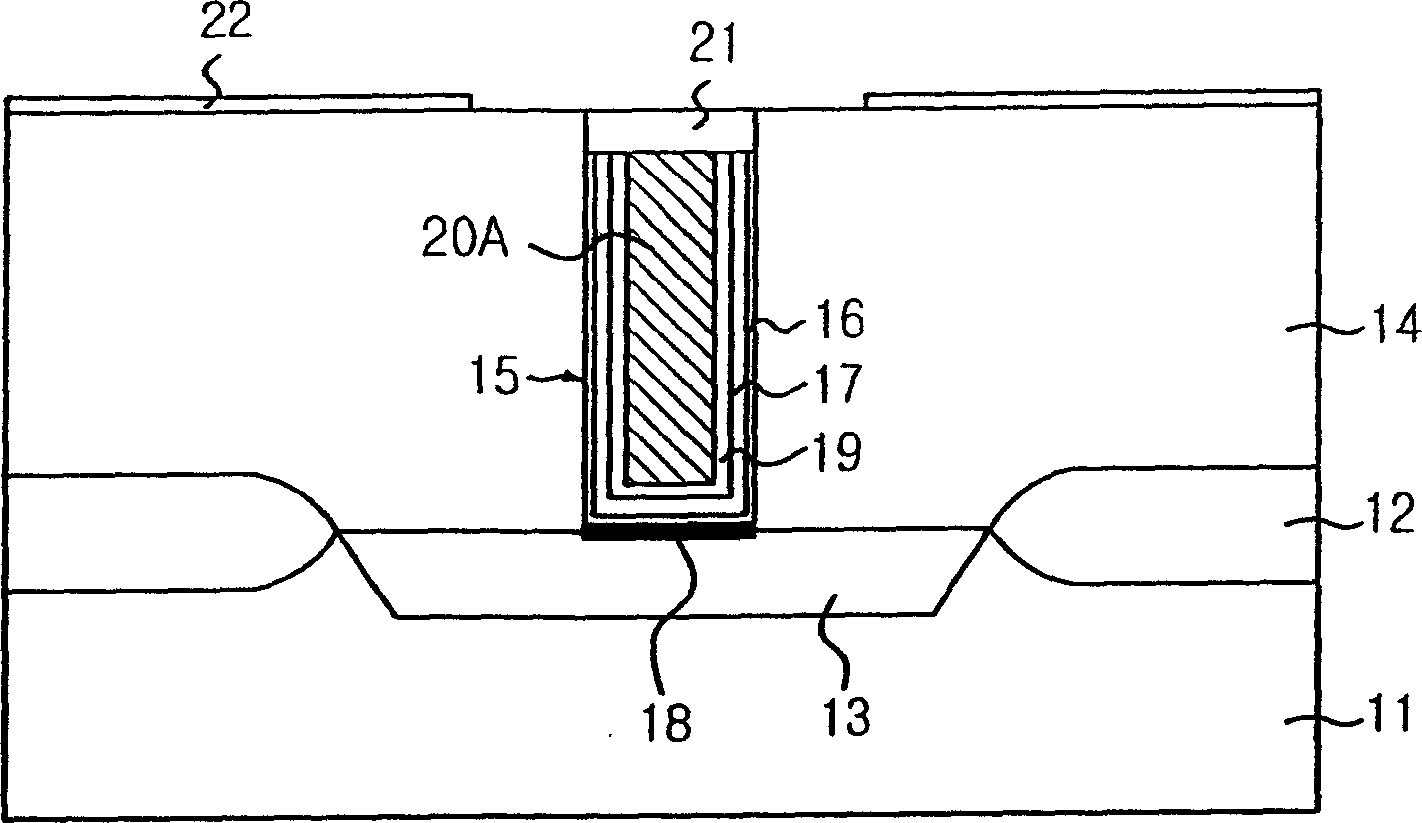

[0038] Figures 4A-4G revealed Figures 7A-7HIt is the manufacturing process of the FeRAM of the first preferred embodiment of the present invention.

[0039] refer to Figure 4A A field oxide layer 32 is grown on the substrate 31, and an impurity junction region 33, such as a source / drain region of a transistor, is formed on the substrate 31. Then, a first interlayer insulating layer 34 is grown on the substrate 31 . In this example, the first interlayer insulating layer 34 is a multi-layer structure, which can isolate the word line, ferrule plug and bit line before forming the storage node contact structure. Preferably, the first interlayer insulating layer 34 is made of silicon oxide, including high density plasma (HDP) oxide, borophosphosilicate glass (BPSG), phosphosilicate glass (PSG), medium temperature oxide (MTO) , high tem...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com