Separation heat-pipe type absorbing ice machine used for ship

An ice maker and heat pipe technology, which is applied in the field of adsorption refrigeration, can solve the problems of limited heat transfer effect and increased power consumption, and achieve the effects of improving energy utilization, saving energy, and improving utilization

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

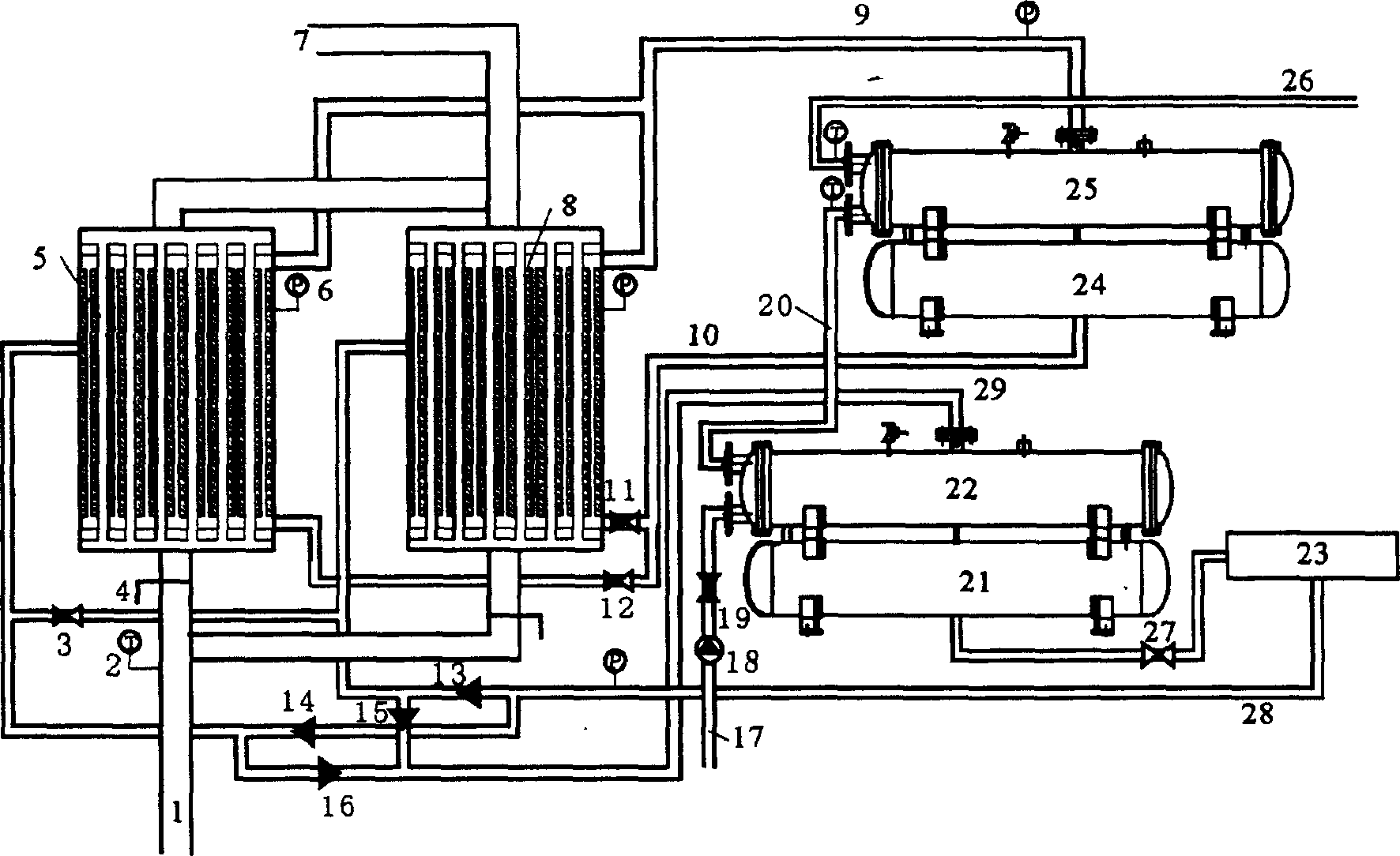

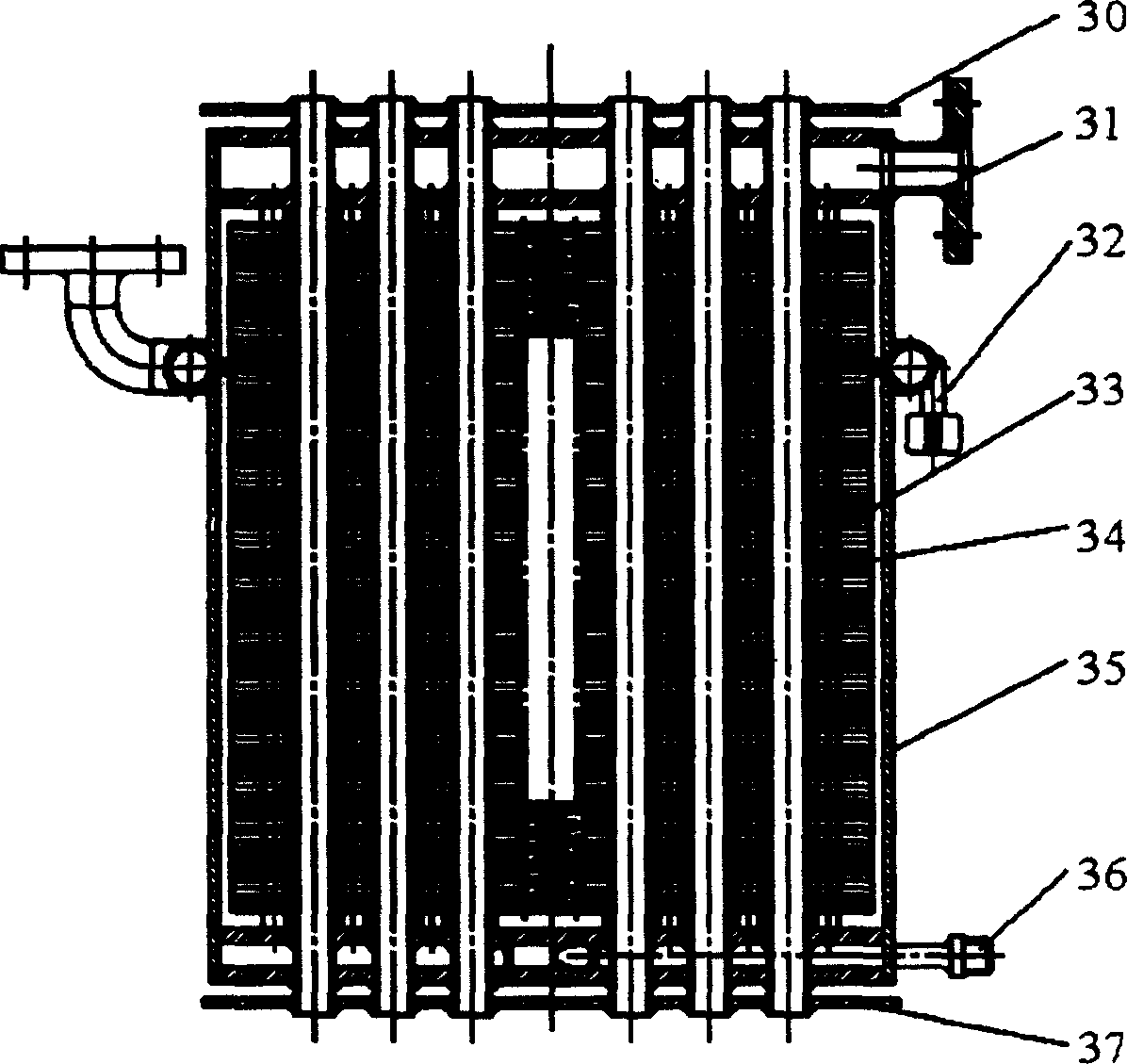

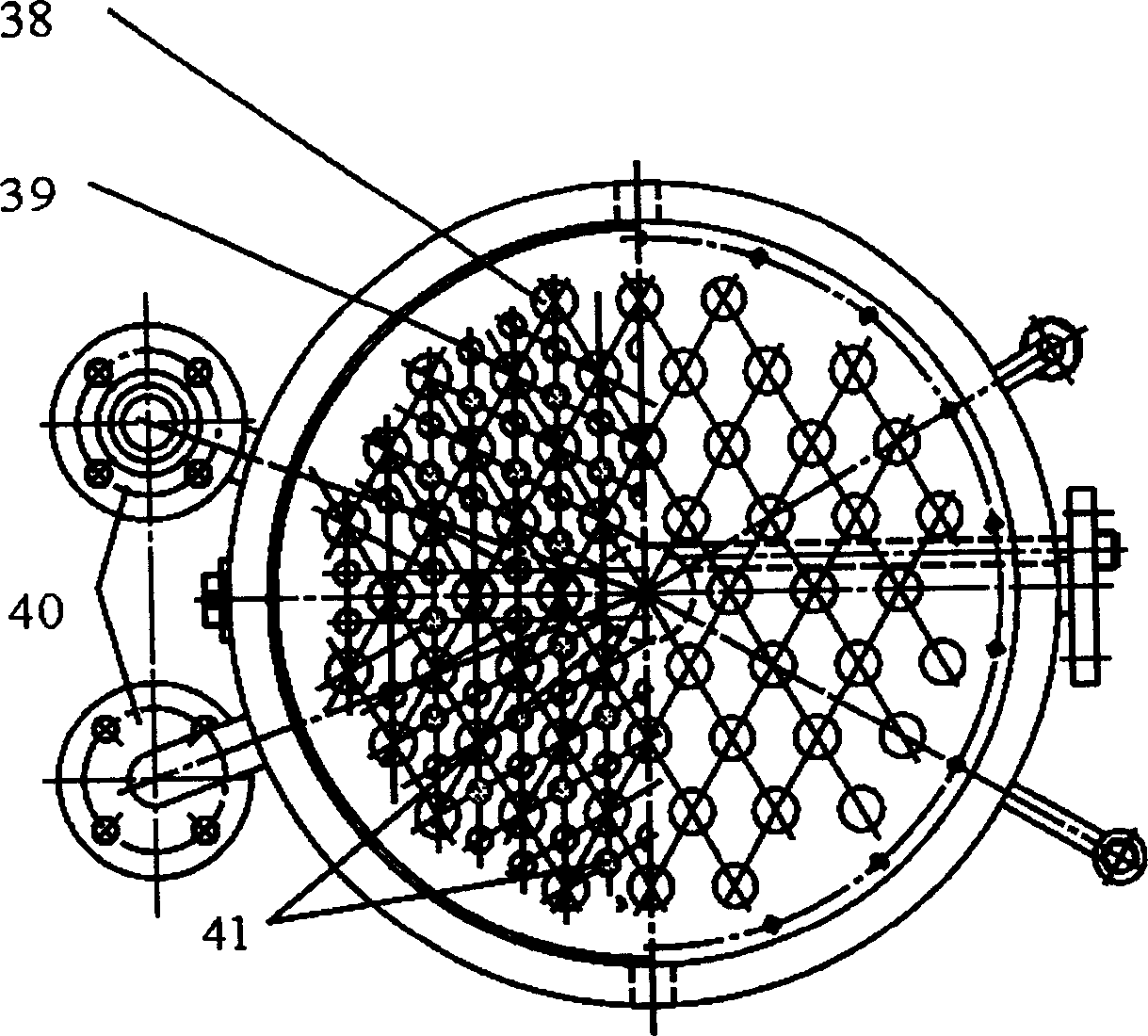

[0019] Such as figure 1 As shown, the present invention includes: flue gas inlet 1, thermometer 2, mass return valve 3, flue gas valve 4, adsorption beds 5, 8, pressure gauge 6, flue gas outlet 7, heat pipe ascending section 9, heat pipe descending section 10, Solenoid valve 11, 12, one-way valve 13, 14, 15, 16, cold sea water inlet 17, cold sea water pump 18, sea water valve 19, cold sea water circuit 20, ammonia tank 21, 24, condenser 22, flake ice machine 23 , Intercooler 25, cold sea water outlet 26, throttle valve 27, take over 28,29. The connection method is as follows: the thermometer 2 and the flue gas valve 4 are set on the flue gas inlet 1 pipeline, the intercooler 25 and the ammonia tank 24 are welded together through the pipeline, and the adsorption beds 5 and 8 pass through the rising section 9 of the heat pipe and the descending section of the heat pipe. Segment 10 is connected. Solenoid valves 11, 12 are arranged on the descending section 10 of the heat pipe, ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com