Method for preparing (NH4)2MoS4

A technology of ammonium tetrathiomolybdate and ammonium paramolybdate, which is applied in the field of preparation of high-purity chemicals and can solve the problems of failing to improve the treatment of hydrogen sulfide gas, large amounts of sodium sulfide and phosphoric acid, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

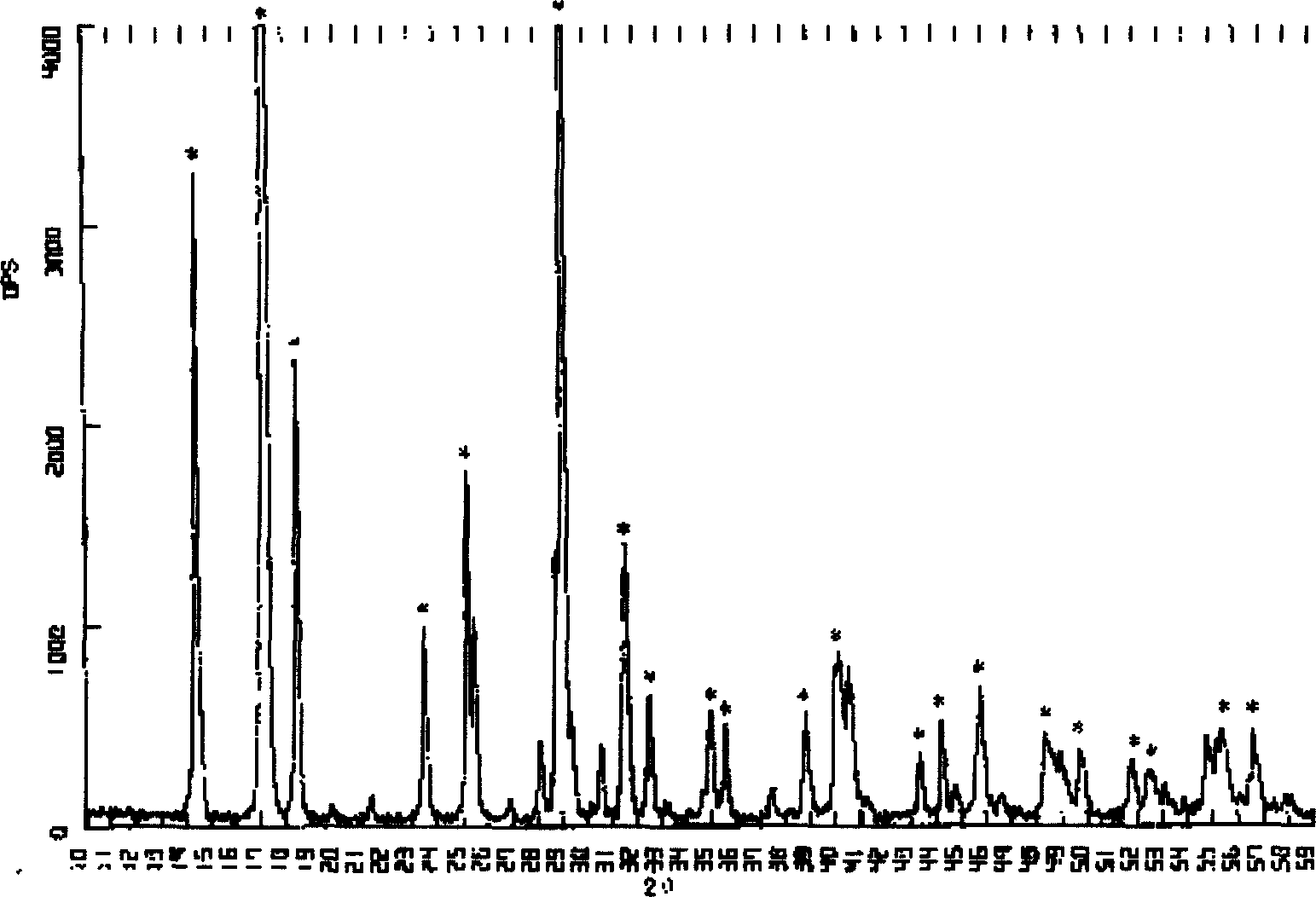

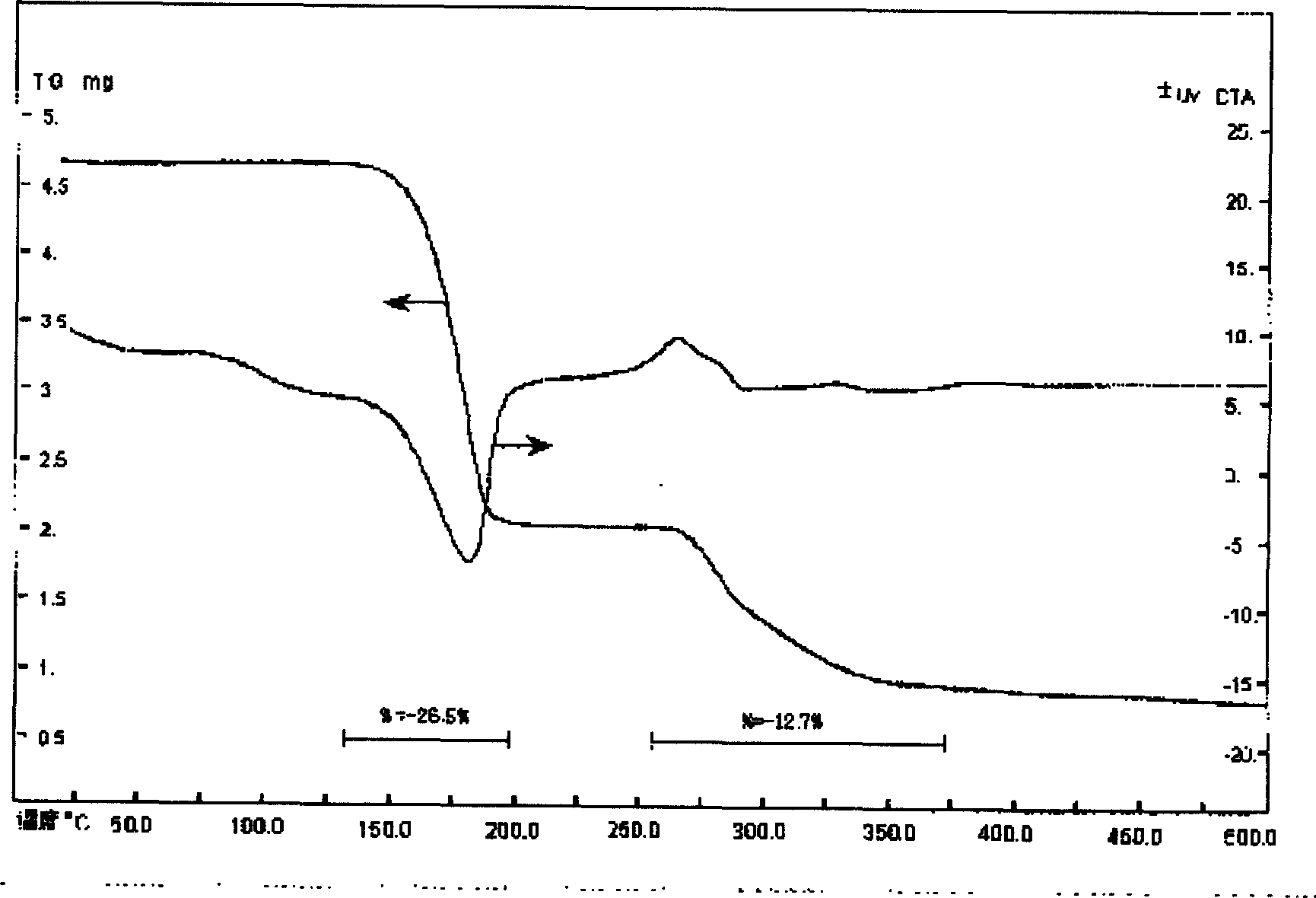

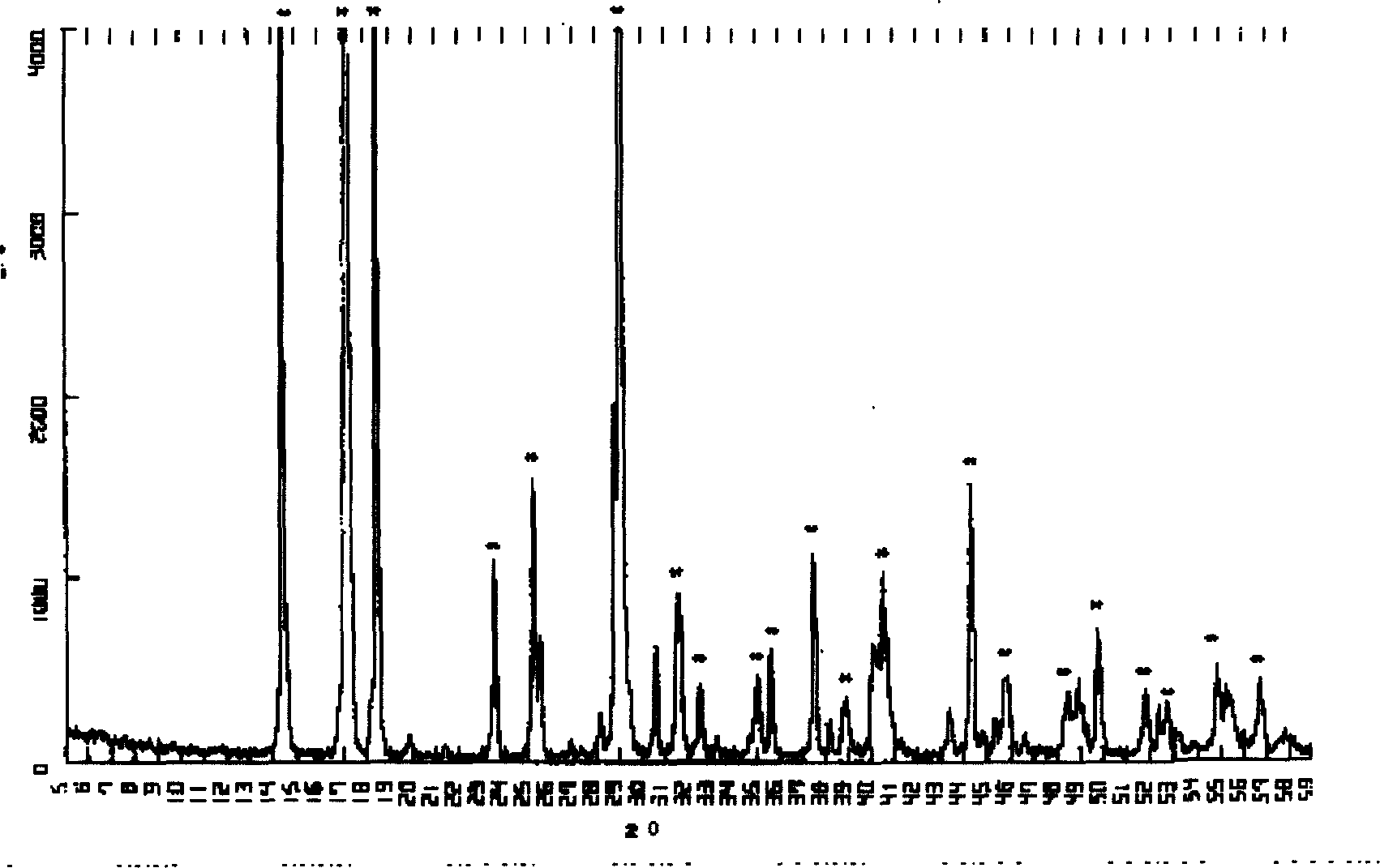

Image

Examples

Embodiment 1

[0014] The 1000ml four-necked bottle that stirrer, reflux condenser and thermometer are equipped with is installed in water bath, takes by weighing 50g ammonium paramolybdate [(NH 4 ) 6 Mo 7 o 24 4H 2 O] Put the powder into a four-necked bottle, add 200ml of distilled water, and then add 60ml of concentrated ammonia water, stir and heat to 40-50°C to dissolve. Under stirring, 450 ml of ammonium sulfide solution with a sulfur content of 8% was added to the solution, the temperature was raised to 60-70° C., and the reaction was stirred for 1.0 hour to obtain a blood-red liquid. After the reaction, the reactant was cooled to room temperature and allowed to stand still for crystallization for 12 hours. Suction filter the liquid containing crystals with a Buchner funnel, wash with 1200ml cold distilled water 3 times (400ml each time), and finally wash the crystals 3 times with 600ml absolute ethanol (200ml each time), drain the solvent and place at room temperature After dryin...

Embodiment 2

[0019]Install a 1000ml four-necked bottle equipped with a stirrer, a reflux condenser and a thermometer in a water bath, weigh 30g of molybdenum trioxide powder into the four-necked bottle, add 200ml of distilled water, then add 60ml of concentrated ammonia water, stir and heat to 40 Dissolved at ~50°C. Under stirring, 360 ml of ammonium sulfide solution with a sulfur content of 8% was added to the solution, the temperature was raised to 60-70° C., and the reaction was stirred for 1.0 hour to obtain a blood-red liquid. After the reaction, the reactant was cooled to room temperature and allowed to stand still for crystallization for 10 hours. Suction filter the liquid containing crystals with a Buchner funnel, wash with 900ml of cold distilled water 3 times (300ml each time), and finally wash the crystals with 450ml of absolute ethanol 3 times (150ml each time), drain the solvent, and place at room temperature After drying for 24 hours, 50.3 g of dark red needle crystals can b...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com