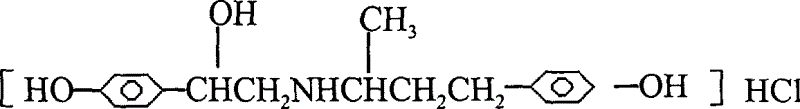

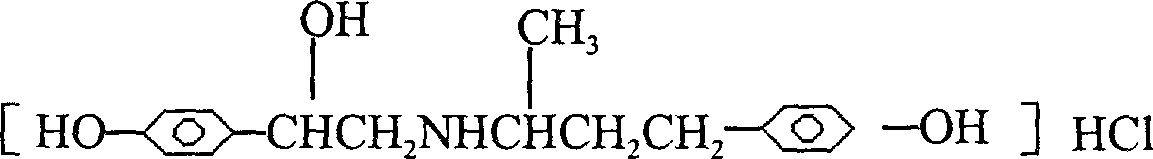

Novel process for preparing ractopamine from p-hydroxyacetophenone and raspberry ketone

A technology of p-hydroxyacetophenone and ractopamine, which is applied in the field of preparation of organic compounds, can solve the problems of low yield of N-alkylation reaction, high market price, and influence on yield, and achieves less by-products and better synthesis Simple steps and good quality results

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0037] Add 300 milliliters of carbon tetrachloride, 25.0 grams of p-hydroxyacetophenone in a 500 milliliter four-neck round bottom reaction flask with magnetic stirring, reflux condenser, chlorine conduit and thermometer, heat to reflux (temperature is 85 ℃), pass Chlorine gas was added to react, and the end point was determined by spotting on a thin-layer chromatographic plate. After the reaction, cool down, add sodium bicarbonate to neutralize, filter, concentrate and crystallize the filtrate, and obtain white crystals after drying.

[0038] Yield: 25.1 Yield: 85%

[0039] Melting point: 130-132°C

[0040] Elemental Analysis: C 8 h 7 o 2 CL M.W.: 170.6

[0041] Theoretical value: C56.32 H4.14 Cl20.78

[0042] Analytical value: C56.09 H4.06 Cl21.12

Embodiment 2

[0044] Add 100 milliliters of 10% sodium carbonate aqueous solution, 100 milliliters of ethyl acetate, 8.2 grams (50 mmol) of 1-methyl-3-(4-hydroxyphenyl)-propylamine and 10.0 g (60 mmol) of -chloro-p-hydroxyacetophenone, stirred vigorously at room temperature. In the first few minutes, all the reactants were dissolved into a brownish-red solution. After about one hour, a large amount of white precipitates began to be produced, and the reaction was completed after about 4 hours.

[0045] Filter with suction, wash with ethyl acetate and distilled water three times each, and drain.

[0046] Transfer the filter cake into a 500ml flask, add 100ml of water, add concentrated hydrochloric acid dropwise until pH = 2, heat to reflux, stir to acidify, and cool to crystallize.

[0047] Yield: 6.0 g Yield: 40.8%

[0048] Melting point: 105-107°C

[0049] Elemental Analysis: C 18 h 22 o 3 CL M.W.: 335.8

[0050] Theoretical value: C64.37 H6.60 N4.17 Cl10.56

[0051] Analytical value:...

Embodiment 3

[0053] Add 30.0 grams (90 mmol) of the white powdery product obtained in Example 2 in a 1000 milliliter hydrogenation reactor, 3.0 grams of Raney nickel, 500 milliliters of absolute ethanol, and hydrogenate at 8Mpa at 140°C until no hydrogen is absorbed.

[0054] After the hydrogenation is completed, filter, and the filtrate is distilled under reduced pressure to remove ethanol, and dried to obtain a light yellow solid product, which is Ractopamine Hydrochlide.

[0055] Melting point: 137-139°C

[0056] Yield: 29.7 g Yield: 99%

[0057] Elemental Analysis: C 18 h 23 o 3 CL M.W.: 337.83

[0058] Theoretical value: C63.99 H7.16 N4.15 Cl10.49

[0059] Analytical value: C63.69 H7.03 N4.08 Cl10.36

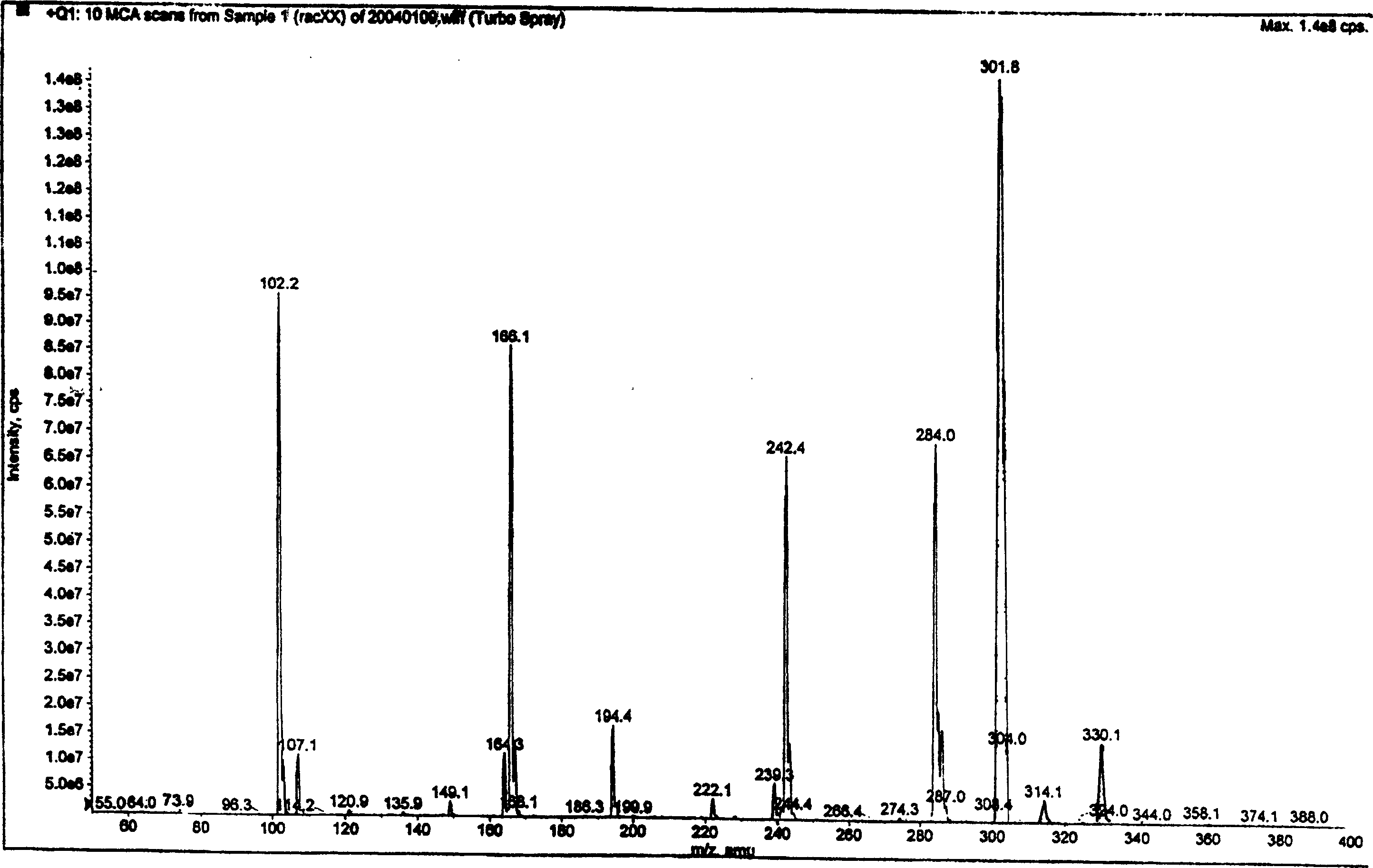

[0060] (The results of product mass spectrometry are shown in the attached figure 1 :)

PUM

| Property | Measurement | Unit |

|---|---|---|

| Melting point | aaaaa | aaaaa |

| Melting point | aaaaa | aaaaa |

| Melting point | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com