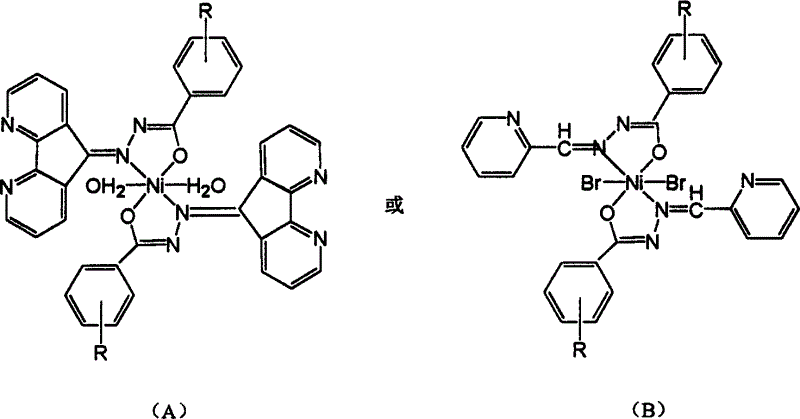

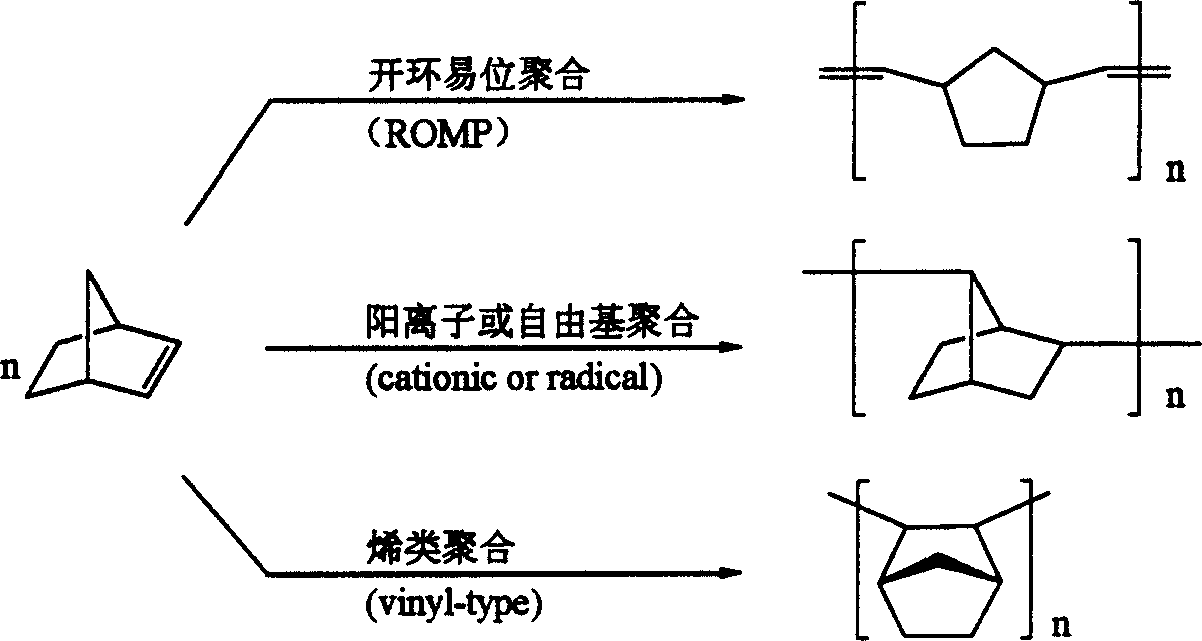

Catalysis system of nitrogen-accessory ingredient of oxygen and nickel in use for polymerizaton of norborene and ramification, preparation method and application

A norbornene and catalytic system technology, applied in the field of nitrogen-oxygen nickel complex catalytic system and preparation thereof, can solve problems such as waste of norbornene resources, and achieve the effects of easy availability of raw materials, simple preparation and high catalytic activity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0027] 1.N, the preparation of O ligand: 3 millimoles (mmol) 4,5-diazafluoren-9-ketones are dissolved in 30 milliliters (ml) absolute ethanol, and add the p-toluene of catalytic amount Sulfonic acid, reflux and stir for 10 minutes; add 3 mmoles of benzoylhydrazide to the absolute ethanol solution of 4,5-diazafluoren-9-one; reflux and stir for 5 hours, concentrate the solution to the original 1 / 3. Filter to obtain a yellow-white precipitate. The yellow-white precipitate was recrystallized in absolute ethanol to obtain yellow-white crystals. Yield: 90%, product confirmation: EI-MS (m / z): 30O (M + , 61.0%), 197 (15.7%), 181 (16.9%), 169 (13.7%), 154 (7.9%), 139 (3.6%), 122 (10.1%), 105 (100%), 94 (5.6 %), 77 (33.7%).

[0028] 2. Preparation of catalyst: under reflux, dissolve 1 mmol of the above-mentioned yellow Schiff base in 15 milliliters of absolute ethanol, then add dropwise 10 milliliters of absolute ethanol solution with 0.5 mmol of nickel acetate tetrahydrate, and rea...

Embodiment 2-7

[0031] Embodiment 2-embodiment 7 N, the preparation of O ligand and catalyst are identical with embodiment 1, and the conditions and the result of norbornene polymerization are shown in Table 1:

[0032] Reality

Embodiment 8

[0034] 1, the preparation of catalyst: preparation method is with embodiment one.

[0035] 2. Norbornene polymerization: Vacuumize the dry 100 ml Schlenk bottle with a stirring magnet, and replace it with nitrogen three times, so that the reaction system is in a nitrogen environment, add 5 μmol of the catalyst described in step 2, and 19.32 ml of toluene , then add 3.89 milliliters of toluene solution containing 2.3538 grams of norbornene (norbornene monomer and catalyst molar ratio is 5000), after stirring for 5 minutes at 25 ℃, add 1.79 milliliters of procatalyst MAO (MAO / catalyst molar ratio is 500), after reacting for 240 minutes at 25°C, add 15 milliliters of isobutanol to terminate the polymerization, then add 80 milliliters of 5‰ hydrochloric acid ethanol (volume ratio), stir at room temperature for 10 hours, then filter after standing for 2 hours, Gained polymer was vacuum-dried at 80° C. for 48 hours to obtain 1.54 grams of polymer, with a conversion rate of 65.6%, an...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Conversion rate | aaaaa | aaaaa |

| Active | aaaaa | aaaaa |

| Active | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com