Coiled material finish coating and preparing method thereof

A technology of topcoat and coil, applied in the field of coatings, can solve the problems of difficulty in high-speed roller coating construction, poor adaptability, slow drying and curing speed, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

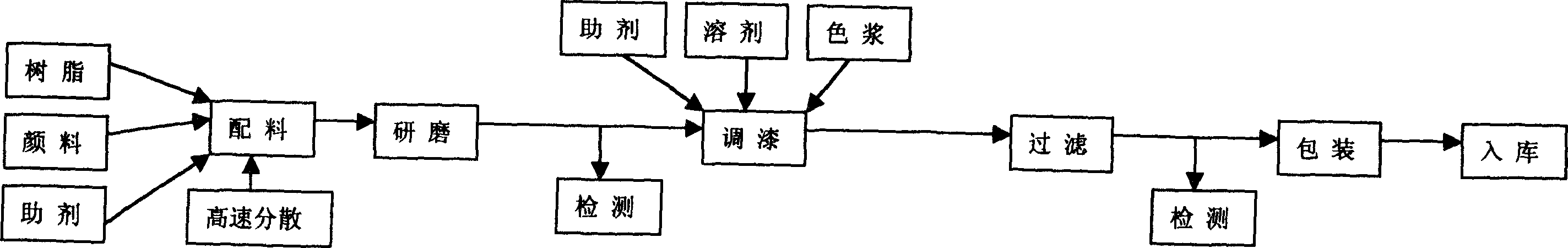

Method used

Image

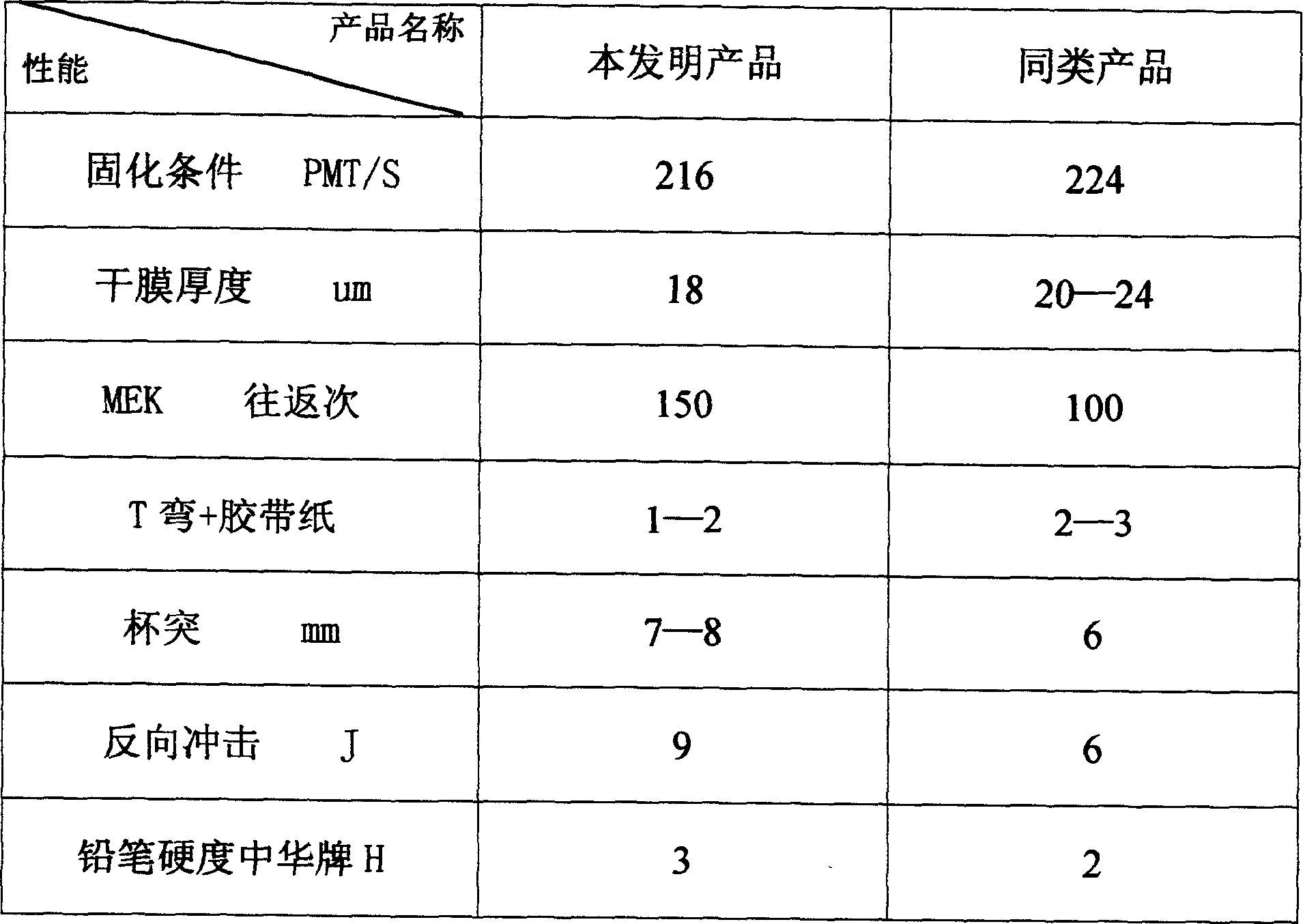

Examples

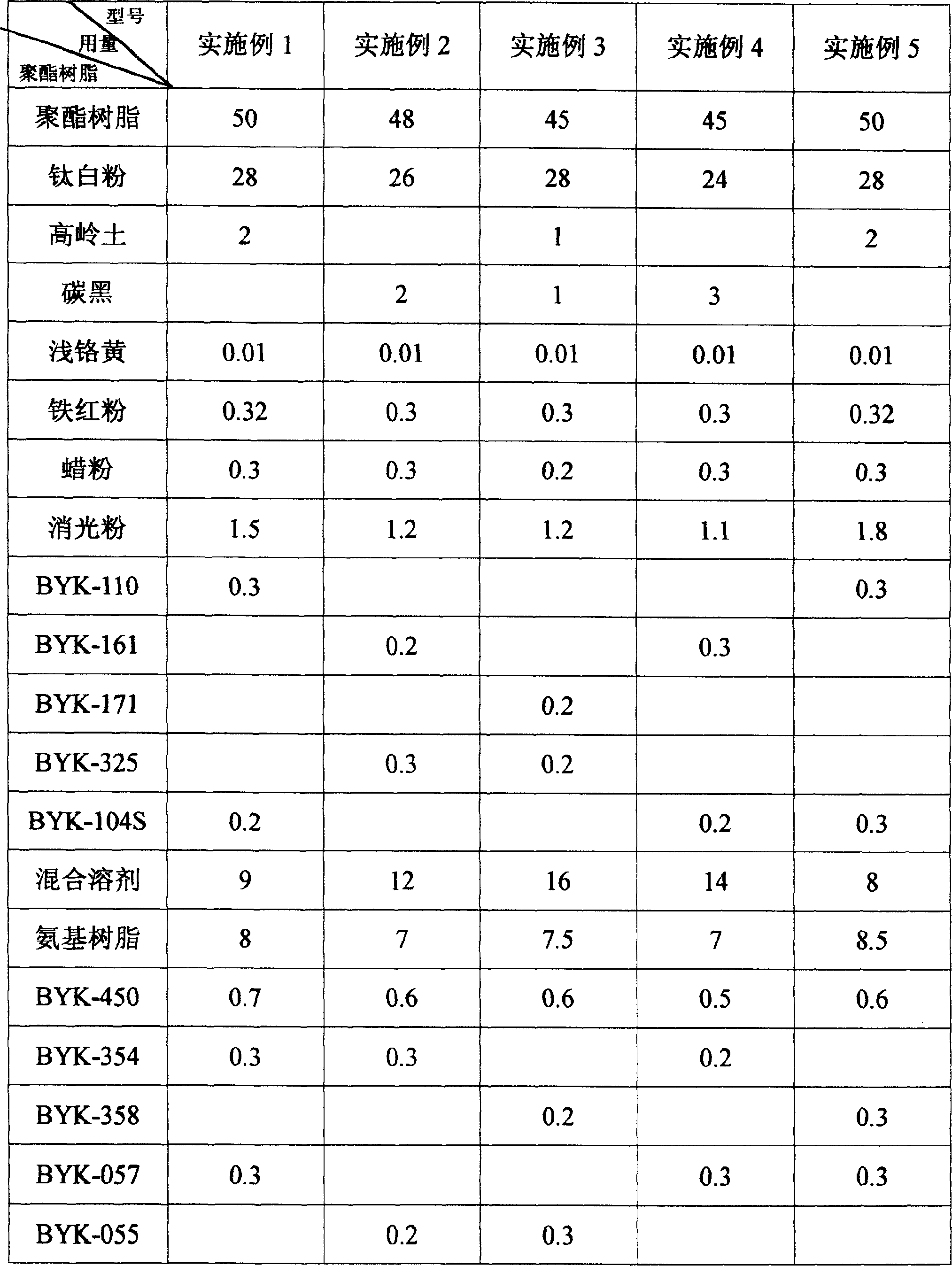

Embodiment 1

[0019] Preparation of linear polyester resin: First, check the running condition of the equipment, the heating system is normal, check the materials according to the following formula, and the measurement is accurate, that is, neopentyl glycol 20kg, propylene glycol 10kg, trimethylolpropane 6kg, hydroxyterol 11kg, ethanol Diacid 15kg, isophthalic acid 35kg, catalyst 0.05kg, ethylene dibutyl ether 10kg, 150#34kg, DBE10kg; put the materials into the reaction equipment, fill the water separator with xylene, seal the reaction kettle, open the vent valve, Start to heat up, stir, heat up to 200°C, reflux for 2 hours, continue to heat up to 230°C, dehydration polycondensation until the acid value is less than 5mgKOH / g, cool down to below 190°C, add ethylene glycol butyl ether and 150# to adjust the viscosity to 20- 30C / 25°C, filter and test below 150°C to obtain a clear and transparent linear polyester resin, which is ready for use.

[0020] Preparation of white-ash coil topcoat: che...

Embodiment 2-5

[0022] According to the material proportioning described in table 3, the method described in embodiment 1 produces lime coil topcoat paint, the product performance of gained is shown in table 4, and wherein linear polyester resin can be the product that supplies on the market, also can be our company homemade products.

Embodiment 6-10

[0024] According to the material ratio described in Table 5, the method described in Example 1 is used to produce crimson coil topcoat paint, and the properties of the product obtained are shown in Table 6, wherein the linear polyester resin can be the product supplied on the market, or it can be produced by our company. homemade products.

PUM

| Property | Measurement | Unit |

|---|---|---|

| acid value | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com