Shaping circular light three differential confocal microscope

A differential confocal and ring light technology, applied in the direction of microscopes, optics, optical components, etc., can solve problems such as side lobe increase, ambient temperature drift, and nonlinear error increase of axial response curve, so as to improve lateral resolution ability, extended axial range, and improved tomographic accuracy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

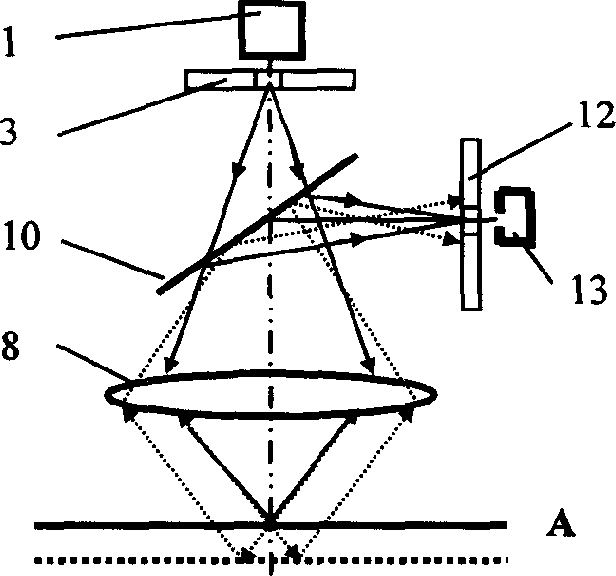

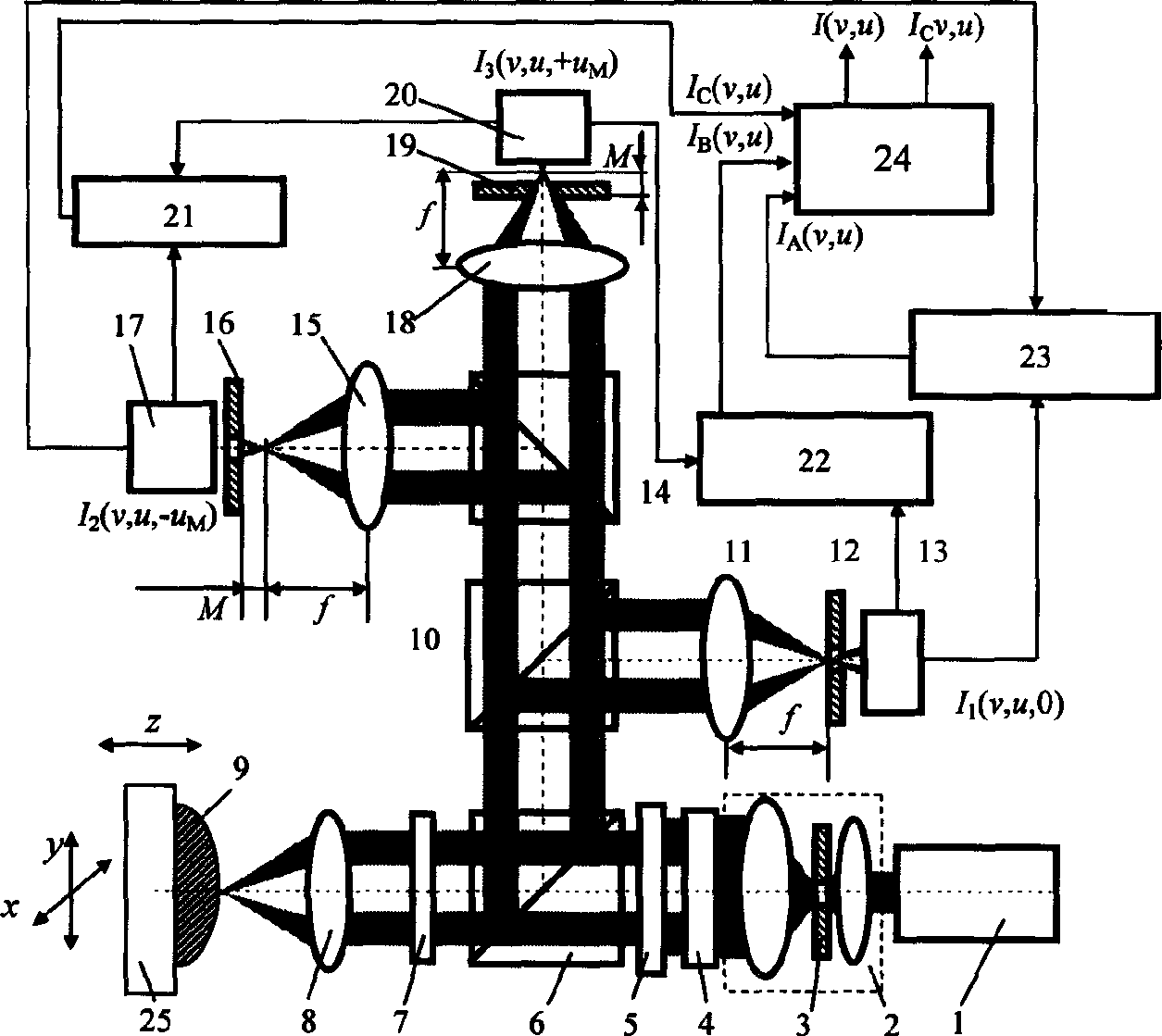

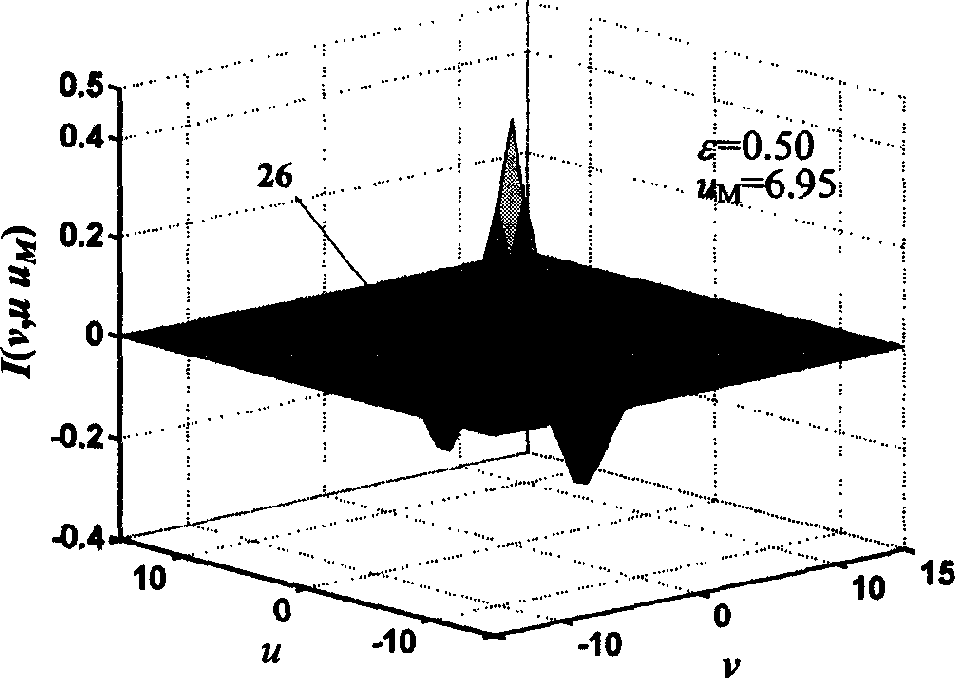

[0032]The technical principle of the present invention is: using the three-differential confocal microscopic imaging technology, the receiving optical path of the confocal microscope is arranged as a three-way detection light path of far focus, focal plane and near focus, and the three-way intensities with different phases detected by the three-way detection system Response signals are differentially subtracted in pairs to achieve the purpose of improving axial resolution and anti-interference ability; in addition, by increasing the proportion of high-frequency light in the laser beam irradiation system, the main Airy disk of the three-differential confocal microscope system The petal becomes smaller, so as to improve the spatial resolution of the confocal microscope system, and integrate the lateral super-resolution characteristics of the shaped ring light with the axial high-resolution characteristics of the differential confocal microscopy technology, so as to achieve high pe...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com