Nano composite of polypyrrole/organic montmori and its preparation process and application

A nano-composite material, organic montmorillonite technology, applied in the application of the nano-composite material, conductive polypyrrole/organic montmorillonite nano-composite material, the preparation field of the nano-composite material, can solve the coating adhesion , impact resistance, bending resistance and other physical and mechanical properties have a great influence, the antistatic effect has a great influence on dry and humidity, and the polymer structure varies greatly, so as to achieve the effects of low price, good application and promotion prospects, and simple equipment and process.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0056] Embodiment 1 Preparation of organomontmorillonite

[0057] First, add 10.0g of sodium montmorillonite to 300ml of water, stir and heat up to 80°C to form a water dispersion, then add 100ml of polyvinylpyrrolidone (K30, Shanghai Boao Biotechnology Co., Ltd.) The aqueous solution of the sodium montmorillonite was slowly added to the aqueous dispersion of sodium montmorillonite, and stirred at 80°C for 12h. Let stand to cool to room temperature, discharge the material, centrifuge and wash to remove impurities 3-5 times, then vacuum-dry at 80°C to constant weight, then grind and refine to obtain polyvinylpyrrolidone-modified organic montmorillonite in the form of white powder .

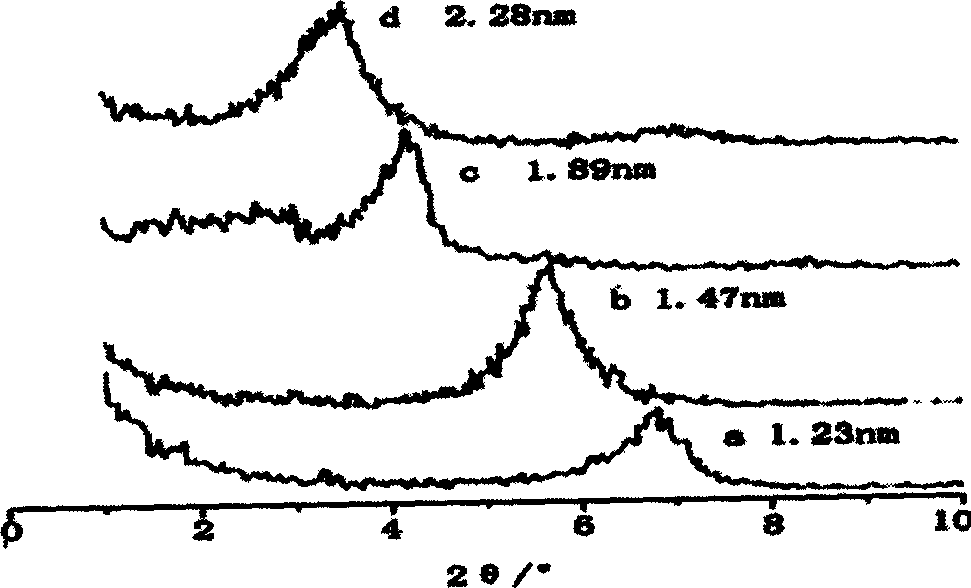

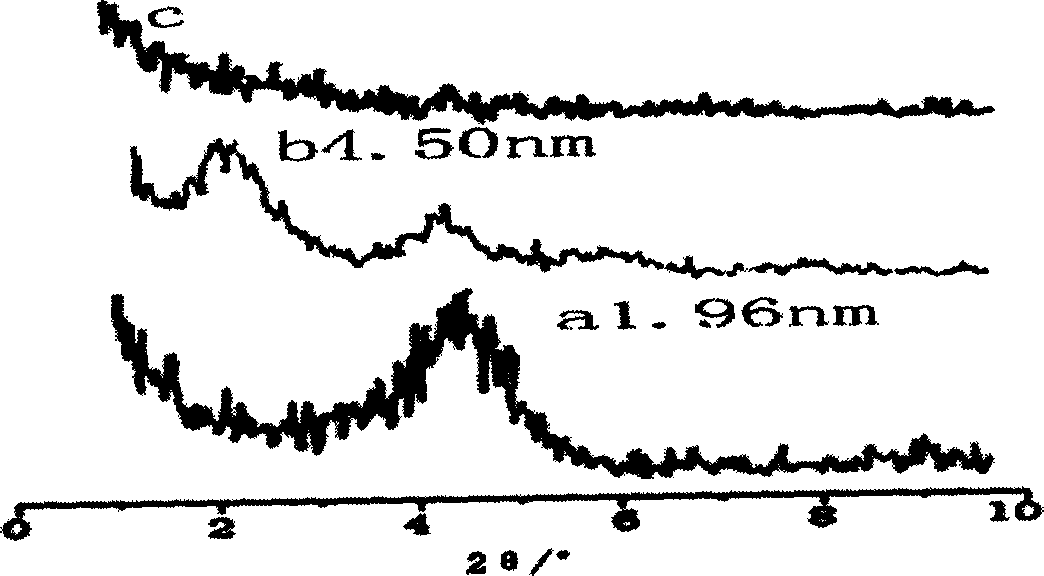

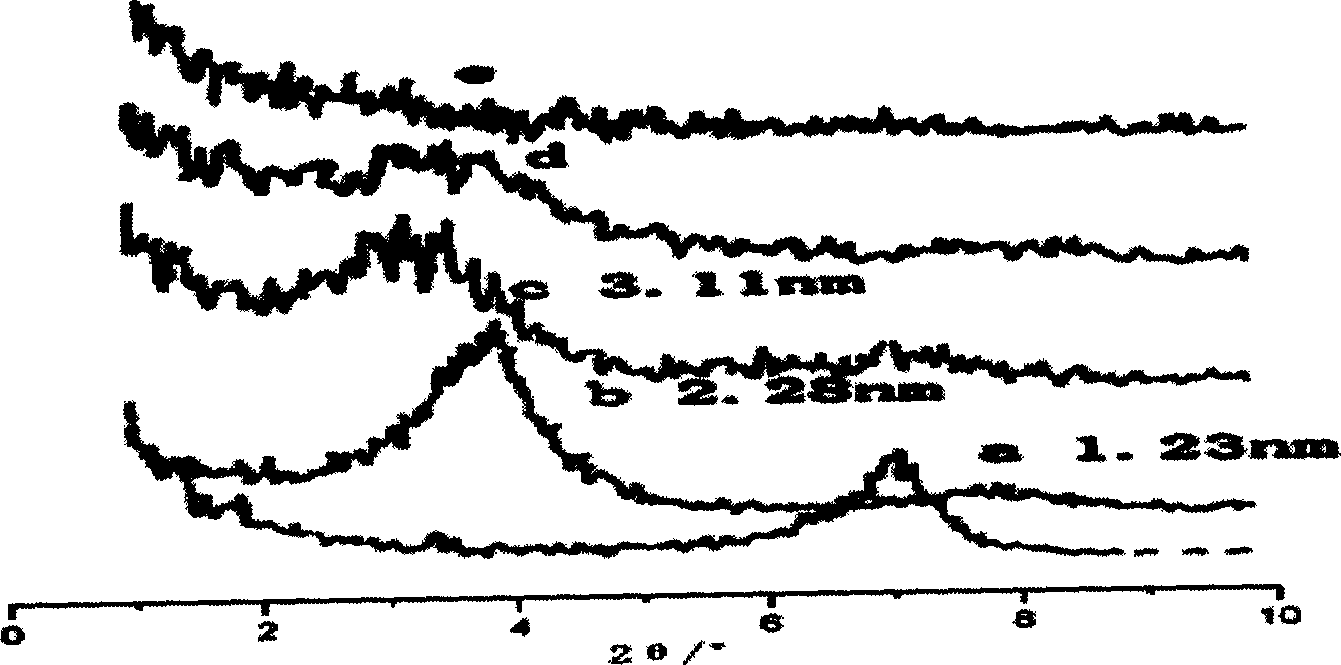

[0058] figure 1 They are sodium montmorillonite (MMT), cetyltrimethylammonium chloride modified montmorillonite (CMMT), cetyltrimethylammonium bromide modified montmorillonite (BMMT) and this X-ray diffraction spectrum of the invented organic montmorillonite (PMMT). In the figure, (a) MMT, (b) ...

Embodiment 2

[0068] The preparation method and reaction condition of organic montmorillonite of the present invention, polypyrrole / organic montmorillonite nanocomposite material are as embodiment 1, adopt the mol ratio of different iron trichloride and pyrrole monomer, gained nanocomposite electrical conductivity As shown in Table 1. It can be seen that too little or too much ferric chloride has an adverse effect on the conductivity of the nanocomposite material. In combination with Example 1, the optimum molar ratio of ferric chloride to pyrrole is about 2.48.

Embodiment 3

[0071] The preparation method and reaction condition of organic montmorillonite of the present invention, polypyrrole / organic montmorillonite nanocomposite material are as embodiment 1, adopt the mass ratio of different pyrrole (Py) and organic montmorillonite, gained nanocomposite material conductivity The rates are shown in Table 2. It can be seen that with the increase of the amount of pyrrole monomer, the electrical conductivity of the composite material increases. In combination with the results of Example 1, it can be known that the electrical conductivity of the composite material can be controlled at 10% by adjusting the amount of pyrrole monomer. -10 S cm -1 -15.30S·cm -1 between.

[0072] pyrrole and organic

quality of montmorillonite

volume ratio

0.00

0.02

0.05

0.10

0.15

0.20

(S cm -1 )

2.86×10 -10

2.15×10 -9

1.31...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Conductivity | aaaaa | aaaaa |

| Conductivity | aaaaa | aaaaa |

| Conductivity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com