Sewage treatment process

A sewage treatment and sewage technology, applied in the direction of water/sewage multi-stage treatment, water/sludge/sewage treatment, chemical instruments and methods, etc., can solve the problems of incomplete equipment, long hydraulic retention time, low back pressure rate, etc. problems, to achieve the effect of increasing the separation efficiency of sewage, the effect of nitrogen and phosphorus removal, and the improvement of reaction rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

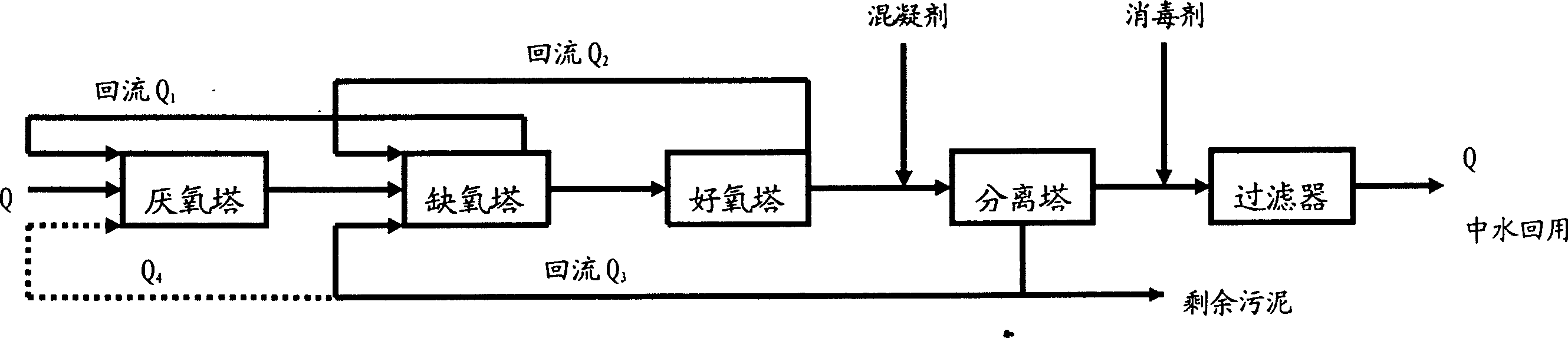

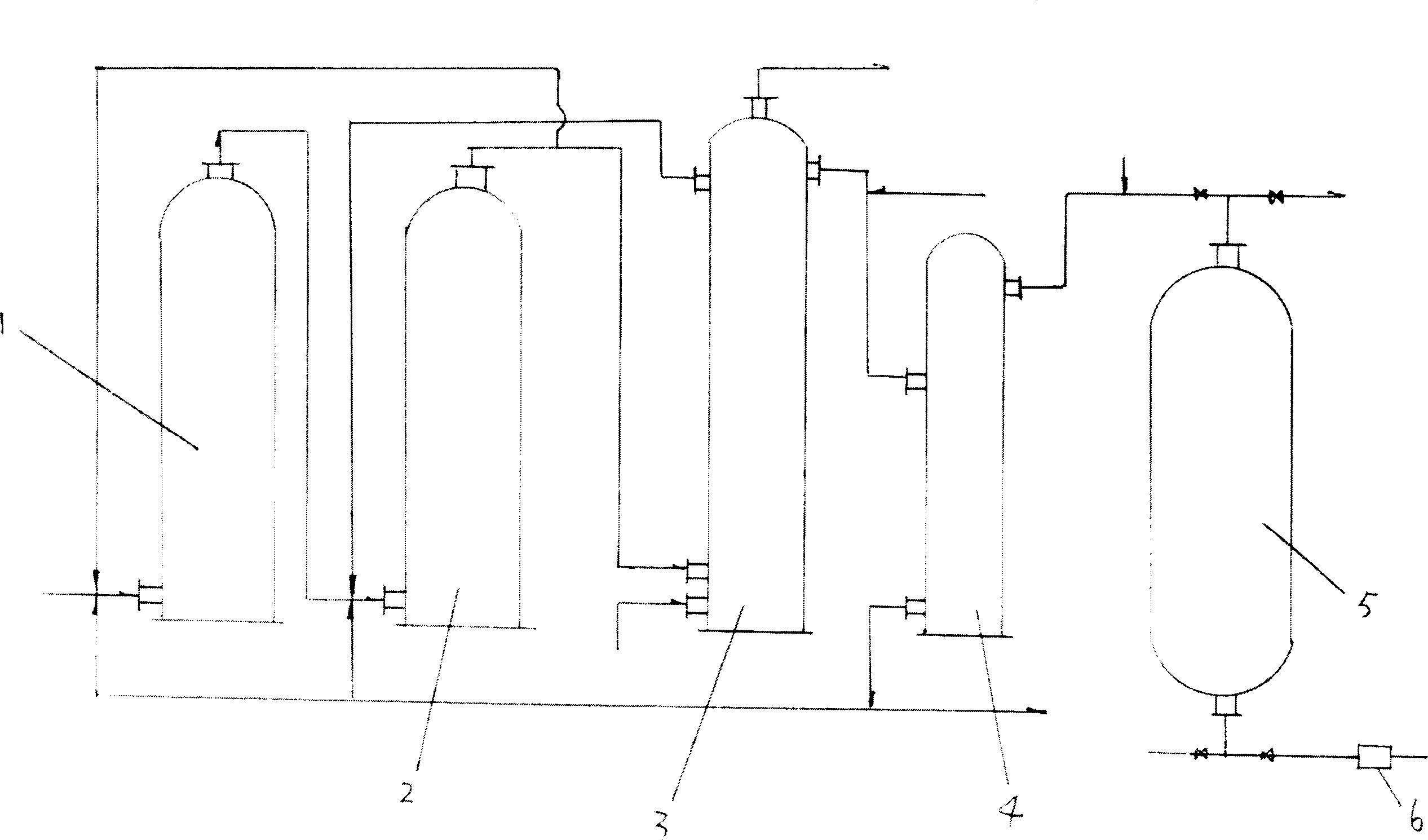

[0019] see figure 1 and figure 2 , the sewage enters from the bottom of the anaerobic tower 1, reacts under anaerobic conditions in the anaerobic tower 1, and the sewage comes out from the top of the anaerobic tower 1 and enters the bottom of the anoxic tower 2, and the anoxic condition in the anoxic tower 2 After the sewage comes out from the top of the anoxic tower 2, it enters the bottom of the aerobic tower 3 together with the air to carry out biochemical reactions under aerobic conditions. After coming out, add coagulant and enter the tower separator 4 for separation. After the sewage comes out of the tower separator 4, add disinfectant and enter the filter 5 for filtration. After being filtered by the filter 5, it becomes reused water.

[0020] In the above treatment process, the sewage from the anoxic tower 2 can also be returned to the sewage inlet of the anaerobic tower 1 to improve the sewage treatment effect.

[0021] In the above treatment process, the sewage at...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com